Product

R5R6

China Lizhou Hard Alloy Source Factory

Product Name: milling insert

Coating : PVD

Material:Tungsten steel

Classification :

Milling Insert Hot Products

keyword:

lizhou

RDMW(R5R6) Carbide Milling Inserts: Performance, Applications, and Advantages

Introduction

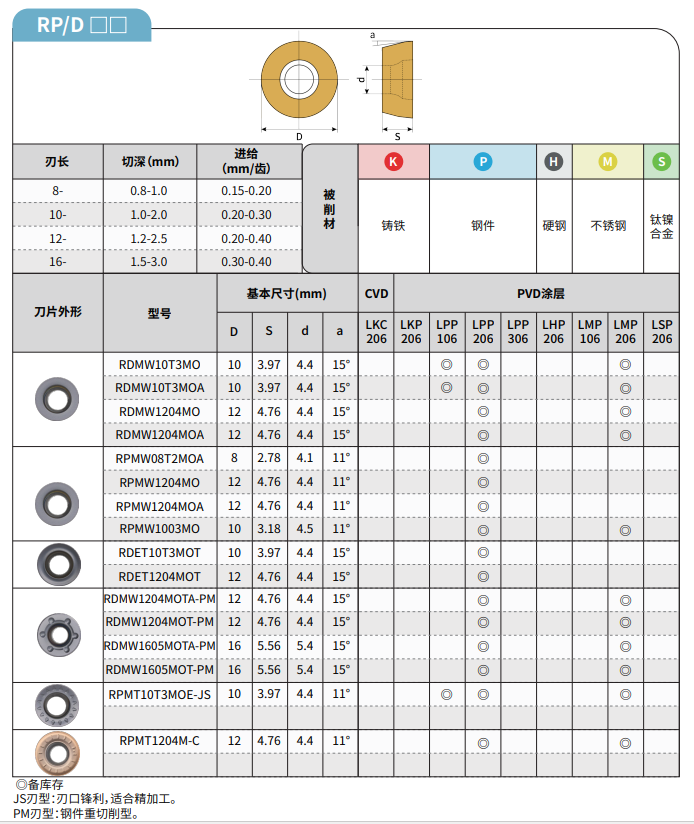

Milling inserts are the core components of modern machining, directly influencing cutting efficiency, surface finish, and tool life. Among them, RDMW(R5R6) carbide inserts (including RDMW10T3MO, RDMW10T3MOA, RDMW1204MO, RDMW1204MA, RPMW08T2MOA, RPMW1204MO, RPMW1204MOA, RPMW1003MO, RPMW10T3MO, RDET10T3MOT, RDET1204MOT, RDMW1204MOTA-PM, RDMW1204MOT-PM, RDMW1605MOTA-PM, and RDMW1605MOT-PM) are widely recognized for their high performance and versatility.

Manufactured from premium carbide material, these inserts are specially engineered for high-speed milling, roughing, semi-finishing, and finishing applications across industries such as aerospace, automotive, mold-making, and general machining.

This article provides a comprehensive overview of RDMW(R5R6) carbide milling inserts, covering their advantages, performance parameters, applications, key features, precautions, and innovative technologies.

1. Advantages of Carbide Inserts in Milling

Carbide milling inserts, compared with high-speed steel (HSS) or ceramic tools, offer unmatched advantages:

Superior Hardness & Wear Resistance

Tungsten carbide, with hardness levels around 92 HRA, ensures long service life.

Excellent wear resistance even under high-speed and heavy-load cutting.

Thermal Stability

Can withstand cutting temperatures above 800°C.

Minimizes tool deformation and maintains sharp cutting edges.

High Efficiency

Supports high-speed machining (HSM), increasing productivity.

Allows deeper cutting depths and higher feed rates.

Versatility

Suitable for a wide range of materials: steel, stainless steel, cast iron, titanium alloys, and non-ferrous metals.

Cost-Effectiveness

Indexable inserts allow multiple cutting edges per insert, reducing tool replacement cost.

RDET10T3MOT-LHP116 (R5) RPMT10T3MOE-JS -LHP106H (R5)

2. Understanding RDMW(R5R6) Parameters

The nomenclature (letters and numbers) of carbide inserts provides critical information for engineers:

R = Round insert shape (offers high strength and durability).

D / P = Insert style or clearance angle.

M / T = Tolerance class and chipbreaker design.

W = Double-sided insert, more cutting edges for economy.

Numbers (10T3, 1204, 1605, etc.) = Insert size: diameter, thickness, corner radius.

Example: RDMW1204 → Diameter 12 mm, thickness 4 mm.

MO, MA, PM = Chipbreaker types for different cutting conditions:

MO: General-purpose medium cutting.

MA: Finishing application with excellent surface finish.

PM: Optimized for steel with balanced performance.

These parameters allow precise selection based on workpiece material, cutting depth, and feed rate.

3. Performance Analysis of RDMW(R5R6) Inserts

The RDMW(R5R6) family offers multiple cutting solutions:

RDMW10T3MO / RDMW10T3MOA

Small-sized inserts for precision milling and fine finishing.

RDMW1204MO / RDMW1204MA

Medium-sized inserts for general-purpose milling in steel and cast iron.

RDMW1605MOT / RDMW1605MOTA-PM

Larger inserts for heavy-duty roughing, ideal for molds and large workpieces.

RPMW08T2MOA / RPMW1204MOA / RPMW1003MO

Round milling inserts for profile milling and copy milling.

RDET10T3MOT / RDET1204MOT

For high-feed milling applications, excellent chip evacuation.

Key Performance Highlights:

Strong cutting edge geometry resists chipping.

Optimized chipbreaker design ensures smooth chip evacuation.

Multi-edge design reduces overall tooling cost.

Capable of machining at speeds up to 250–400 m/min depending on material.

4. Applications and Use Cases

RDMW(R5R6) inserts are widely applied in different machining industries:

Automotive Industry

Cylinder head machining, gear housings, engine blocks.

Aerospace Industry

Titanium alloy structural parts, turbine blades, landing gear.

Mold & Die Manufacturing

Copy milling of molds, die cavities, and 3D contour machining.

General Engineering

Slotting, side milling, face milling of steel and stainless steel parts.

Heavy-Duty Cutting

Large casting and forging components, roughing applications.

5. Key Features of RDMW(R5R6) Inserts

High toughness substrate to resist chipping in interrupted cuts.

Coated grades (CVD / PVD TiAlN, AlTiN, etc.) for extended tool life.

Versatile chipbreakers for stable machining in roughing and finishing.

Indexable design: multiple edges per insert reduce cost.

Round cutting edge geometry provides smoother cutting and longer life.

6. Precautions for Using Carbide Inserts

To maximize insert performance:

Select correct grade: Use wear-resistant grades for cast iron, tougher grades for stainless steel.

Optimize cutting parameters: Follow recommended cutting speed, feed, and depth.

Coolant usage: Apply appropriate coolant in high-temperature materials.

Tool holder inspection: Ensure proper clamping to avoid insert breakage.

Edge utilization: Rotate insert edges to fully use all cutting edges.

7. Technological Innovations & Patents

Modern carbide inserts like the RDMW(R5R6) family integrate advanced manufacturing technologies:

Powder Metallurgy (PM) Technology

Produces ultra-fine carbide grains for higher toughness.

CVD & PVD Coating Innovation

Multi-layer coatings improve wear resistance, reduce friction.

Chipbreaker Design Patents

Specially engineered grooves ensure controlled chip flow, minimizing tool wear.

Finite Element Analysis (FEA) in design stage

Optimized cutting edge geometry for lower cutting forces.

These innovations ensure RDMW(R5R6) carbide inserts deliver superior machining efficiency, stability, and cost savings.

Conclusion

The RDMW(R5R6) series carbide milling inserts are engineered for precision, strength, and versatility. With advanced chipbreaker design, superior carbide substrates, and cutting-edge coating technologies, these inserts excel in high-speed milling, copy milling, heavy-duty roughing, and finishing applications.

By offering excellent wear resistance, thermal stability, and multi-edge economy, RDMW(R5R6) inserts help manufacturers achieve higher productivity, better surface finish, and reduced tool costs.

For industries such as automotive, aerospace, mold-making, and general machining, RDMW(R5R6) carbide inserts remain a trusted solution for efficient and reliable milling operations.

Previous page

Next page

Use equipment

CNC machining centre

CNC machine tools

Carved machine

Factory Board

Factory Board

Factory Board

Factory Board

Factory Board

Recommended products

FAQ

2025-05-29

The naming conventions for turning inserts generally follow international standards (such as ISO standards). The model number consists of a series of letters and numbers, each character representing different geometric parameters or functional characteristics, such as the naming convention for the TNMG160404R-PV turning insert from Lizhou.

2025-05-26

What types of end mills are there?

Materials can be processed according to different types of end mills, categorized by the types of milling tools, including flat end mills, ball end mills, radius end mills, chamfer end mills, and end mills with chip breakers.

2025-05-23

PCD milling cutter is a polycrystalline diamond (PCD) milling cutter, which has a wide range of applications in the field of machining.

2025-05-08

End mill for machining aluminum materials

Many customers have told us that ordinary end mills frequently stick when machining aluminum, and the accumulation of chips affects the accuracy, so they always change the tools. LIZHOU editor suggests that coated end mills are not recommended for aluminum materials, because some coatings contain aluminum elements. Therefore, it is better to choose uncoated end mills when selecting end mills for machining aluminum materials.