Product

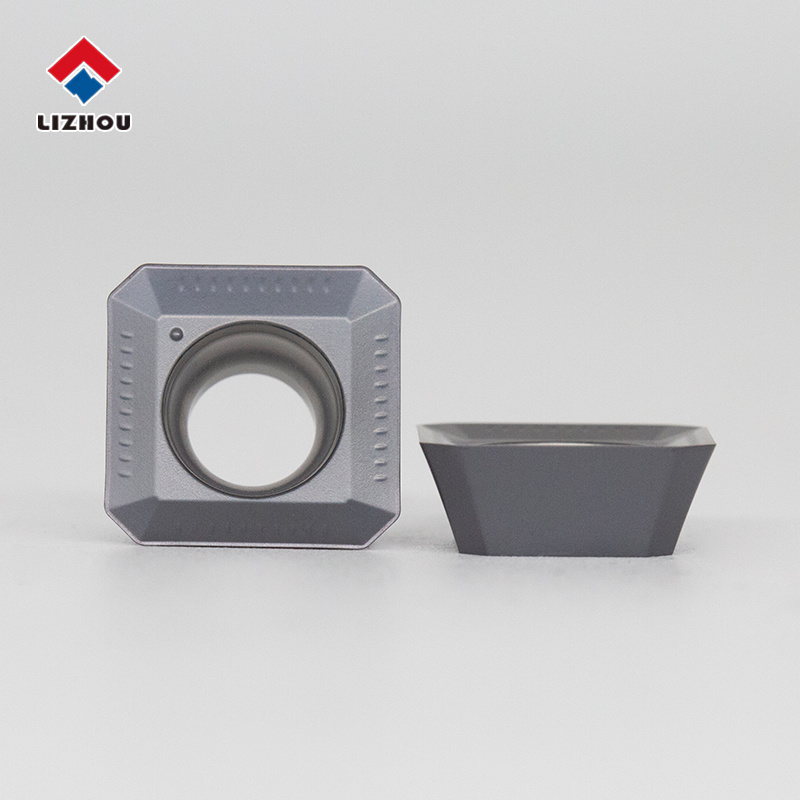

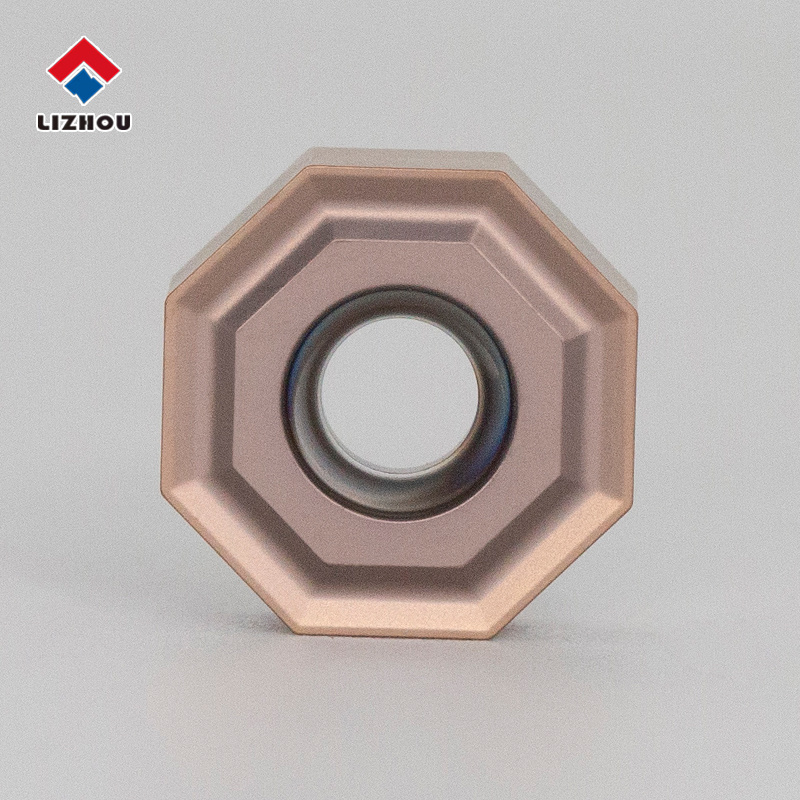

WNMU080608

China Lizhou Hard Alloy Source Factory

Product Name: Milling isnert

Coating : CVD

Material:Tungsten steel

Classification :

Milling Insert Hot Products

keyword:

lizhou

What does WNMU represent in milling inserts?

W represents : Code shape

N represents : Back rake code

M represents : Tolerance code ± 0.08- ± 0.18

U represents : Double-sided perforated groove

Features of WNMU indexable face milling cutters:

1. WNMU is a type of face milling insert. Milling inserts are usually measured by their cutting edges. Please help me write product page content and introduce the characteristics of WNMU products.

2. High metal removal rate: Suitable for rough machining, quickly removing large amounts of material, greatly improving production efficiency.

3. Compatible with various face milling cutters: Compatible with various tool systems, suitable for milling steel, cast iron, stainless steel and other materials.

Why choose our WNMU face milling inserts?

Stable cutting performance, adaptable to various cutting conditions

Various coatings and geometries can be provided according to processing requirements

Professional technical team support, providing selection suggestions and after-sales service

What services can we provide for WNMU milling inserts?

- Free samples

- OEM and ODM customization

- High-efficiency cutting

- Tungsten steel material

Use equipment

CNC machining centre

CNC machine tools

Carved machine

Factory Board

Factory Board

Factory Board

Factory Board

Factory Board

Recommended products

FAQ

2025-05-29

The naming conventions for turning inserts generally follow international standards (such as ISO standards). The model number consists of a series of letters and numbers, each character representing different geometric parameters or functional characteristics, such as the naming convention for the TNMG160404R-PV turning insert from Lizhou.

2025-05-26

What types of end mills are there?

Materials can be processed according to different types of end mills, categorized by the types of milling tools, including flat end mills, ball end mills, radius end mills, chamfer end mills, and end mills with chip breakers.

2025-05-23

PCD milling cutter is a polycrystalline diamond (PCD) milling cutter, which has a wide range of applications in the field of machining.

2025-05-08

End mill for machining aluminum materials

Many customers have told us that ordinary end mills frequently stick when machining aluminum, and the accumulation of chips affects the accuracy, so they always change the tools. LIZHOU editor suggests that coated end mills are not recommended for aluminum materials, because some coatings contain aluminum elements. Therefore, it is better to choose uncoated end mills when selecting end mills for machining aluminum materials.