Product

PNMU face milling cutter

China Lizhou Hard Alloy Source Factory

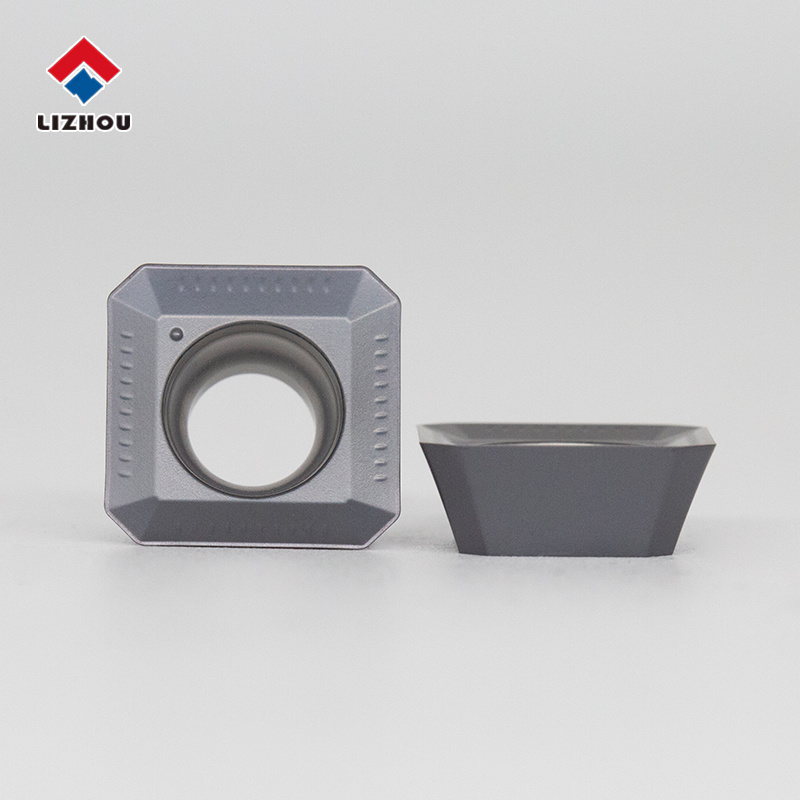

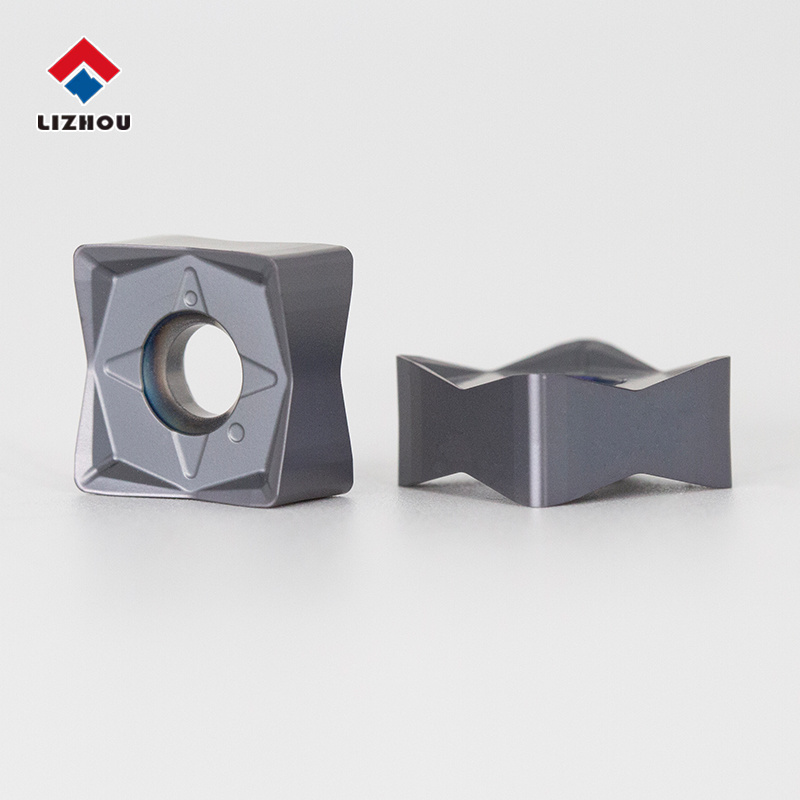

Product Name: milling insert

Coating : CVD

Material:Tungsten steel

Classification :

Milling insert

keyword:

lizhou

PNMU0905XNZR-GM Carbide Milling Insert: Performance, Applications, and Technical Insights

Introduction

The PNMU0905XNZR-GM carbide milling insert is a high-performance cutting tool engineered for modern CNC machining. As one of the most reliable solutions for heavy-duty face milling and shoulder milling, this insert combines the strength of premium tungsten carbide substrates with the durability of multi-layer PVD/CVD coatings.

Manufactured by our company—a professional carbide manufacturer with years of experience in precision tooling—this insert provides outstanding wear resistance, cutting stability, and versatility across a wide range of materials, including steels, stainless steels, cast irons, and exotic alloys.

This article explores the advantages, parameters, applications, and innovations of the PNMU0905XNZR-GM insert, providing a comprehensive guide for manufacturers and engineers seeking high-quality carbide tooling solutions.

1. Advantages of PNMU0905XNZR-GM Carbide Insert

The PNMU0905XNZR-GM milling insert offers numerous advantages compared to conventional inserts:

High Material Removal Rates (MRR) – Optimized chipbreaker geometry allows aggressive cutting without sacrificing stability.

Superior Edge Strength – Engineered for heavy-duty milling, the insert withstands high cutting forces.

Wear Resistance – Multi-layer coatings minimize flank wear, crater wear, and adhesion.

Extended Tool Life – Carbide substrate maintains hardness at elevated cutting temperatures.

Excellent Surface Finish – The insert produces smoother surfaces with reduced vibration.

Versatility – Suitable for steels, stainless steels, cast irons, and even hardened alloys.

2. Decoding PNMU0905XNZR-GM: Parameters and Nomenclature

Every part of the designation PNMU0905XNZR-GM provides insight into its geometry, dimensions, and function.

P – Insert Type (indicating milling insert family).

N – Insert Shape (N usually refers to a 90° cutting edge or neutral geometry).

M – Tolerance Class (M = medium tolerance, balancing accuracy and flexibility).

U – Hole/Chipbreaker Design (special universal chipbreaker design).

0905 – Size Code:

09 = Insert length (9mm nominal).

05 = Insert thickness (5mm nominal).

XNZR – Edge and Geometry Code:

X = Special edge preparation.

N = Neutral rake angle.

Z = Specific clamping system compatibility.

R = Right-hand cutting.

GM – Application Chipbreaker (GM = General Milling, suitable for steels and stainless steels).

This nomenclature ensures machinists can quickly identify the insert’s geometry, size, and application suitability.

3. Performance Analysis

The PNMU0905XNZR-GM insert excels in precision, durability, and cutting efficiency.

Cutting Performance

Capable of high-feed milling with stable chip formation.

Reduces power consumption due to optimized rake angles.

Supports both roughing and semi-finishing operations.

Durability

High cobalt content in the carbide substrate improves fracture toughness.

Advanced PVD/CVD coatings resist abrasive wear and thermal cracking.

Stability

Rigid seating prevents insert movement during aggressive milling.

Reduced cutting vibrations ensure dimensional accuracy.

4. Applications of PNMU0905XNZR-GM Inserts

The versatility of this insert makes it an essential tool in industries such as automotive, aerospace, mold & die, energy, and heavy machinery.

Application Areas

Face Milling – Produces high-quality flat surfaces.

Shoulder Milling – Achieves accurate 90° shoulders.

High-Efficiency Roughing – Ideal for removing large stock rapidly.

Profile Milling – Smooth cutting in contouring and 3D shapes.

Slotting and Grooving – Precise groove machining with reliable chip evacuation.

Suitable Materials

Steels (low to high carbon steels, alloy steels).

Stainless Steels (austenitic, martensitic, duplex).

Cast Irons (gray, ductile, compacted graphite).

Hardened Materials (up to HRC 55 with optimized coating).

Non-Ferrous Alloys (limited with polished edge variants).

5. Features and Technical Characteristics

General Purpose GM Chipbreaker – Ensures efficient chip control across materials.

Robust Geometry – Withstands interrupted cuts and high cutting forces.

High-Precision Tolerance – Maintains dimensional accuracy for interchangeable inserts.

Coating Variants – TiAlN, AlTiN, or CVD multilayers for specific material applications.

Optimized Edge Prep – Enhances tool life and prevents chipping.

6. Precautions and Best Practices

To achieve maximum efficiency and insert longevity, users should follow these best practices:

Correct Cutting Parameters – Adjust cutting speed (Vc), feed per tooth (fz), and depth of cut (ap) based on material.

Coolant Usage – Apply coolant when machining stainless steels and superalloys; dry milling works for cast irons.

Secure Clamping – Ensure proper seating to prevent micro-movements.

Regular Replacement – Replace before excessive wear to protect the cutter body.

Avoid Excessive Vibration – Optimize toolpath and rigidity to extend insert life.

7. Technological and Patent Innovations

The PNMU0905XNZR-GM insert integrates several innovations:

Nano-Coating Technology – Extends tool life through enhanced heat resistance.

Advanced Powder Metallurgy – Ensures uniform carbide grain size for toughness.

Edge Honing Techniques – Strengthens edges against chipping.

Chipbreaker Design Patents – GM geometry provides stable chip evacuation.

Eco-Friendly Manufacturing – Sustainable production methods reduce emissions.

8. Why Choose Our PNMU0905XNZR-GM Insert?

As a leading carbide manufacturer, our factory offers:

Direct Factory Supply – Competitive pricing with no middlemen.

OEM/ODM Services – Custom geometries, grades, and coatings.

Consistent Quality – ISO-certified processes with strict QC.

Technical Support – Machining parameter guidance from experts.

Global Reach – Exported to over 50 countries worldwide.

Conclusion

The PNMU0905XNZR-GM carbide milling insert is an advanced solution for modern milling operations, offering strength, versatility, and extended tool life. Its optimized GM chipbreaker, robust carbide substrate, and advanced coatings make it suitable for machining steels, stainless steels, and cast irons with superior efficiency.

By choosing our hard alloy carbide inserts, manufacturers gain access to reliable, cost-effective, and high-performance solutions that improve machining productivity and reduce overall tooling costs.

Previous page

Next page

Use equipment

CNC machining centre

CNC machine tools

Carved machine

Factory Board

Factory Board

Factory Board

Factory Board

Factory Board

Recommended products

FAQ

2025-05-29

The naming conventions for turning inserts generally follow international standards (such as ISO standards). The model number consists of a series of letters and numbers, each character representing different geometric parameters or functional characteristics, such as the naming convention for the TNMG160404R-PV turning insert from Lizhou.

2025-05-26

What types of end mills are there?

Materials can be processed according to different types of end mills, categorized by the types of milling tools, including flat end mills, ball end mills, radius end mills, chamfer end mills, and end mills with chip breakers.

2025-05-23

PCD milling cutter is a polycrystalline diamond (PCD) milling cutter, which has a wide range of applications in the field of machining.

2025-05-08

End mill for machining aluminum materials

Many customers have told us that ordinary end mills frequently stick when machining aluminum, and the accumulation of chips affects the accuracy, so they always change the tools. LIZHOU editor suggests that coated end mills are not recommended for aluminum materials, because some coatings contain aluminum elements. Therefore, it is better to choose uncoated end mills when selecting end mills for machining aluminum materials.