Product

BLMP fast feed to milling cutter

China Lizhou Hard Alloy Source Factory

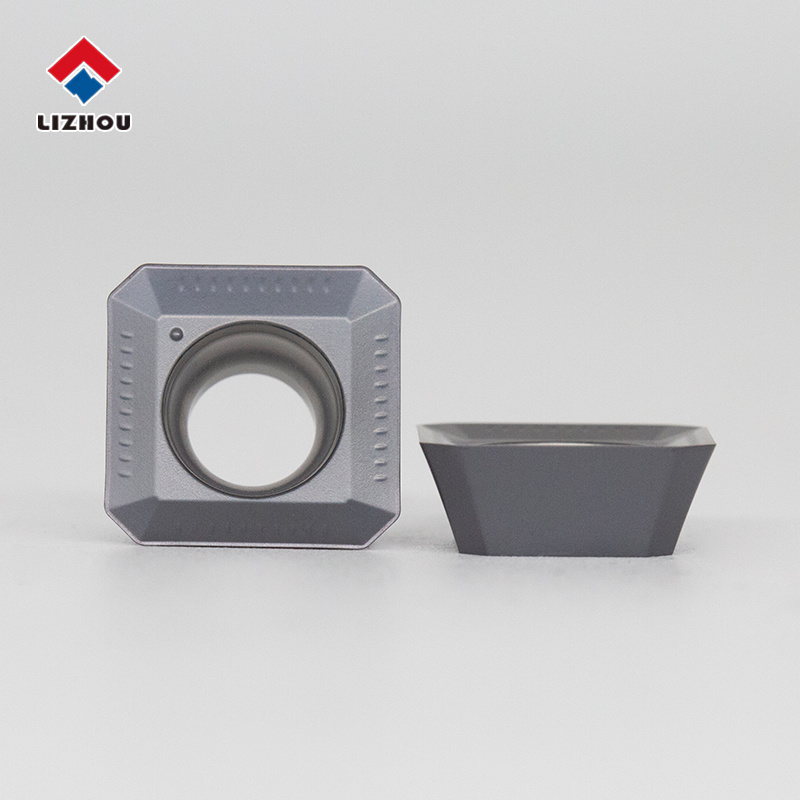

Product Name: milling insert

Coating : PVD

Material:Tungsten steel

Classification :

Milling insert

keyword:

lizhou

BLMP0603R-M Carbide Milling Inserts: High-Precision Cutting Tools for Modern Machining

Introduction

In the ever-evolving field of machining, hard alloy (carbide) inserts have become indispensable for manufacturers seeking high precision, durability, and efficiency. Among the most widely used inserts in high-performance milling applications is the BLMP0603R-M carbide milling insert. Known for its superior cutting efficiency, extended tool life, and excellent adaptability to a wide range of materials, this insert has become a staple in industries such as automotive, aerospace, mold-making, and general engineering.

As a professional carbide manufacturer, our company specializes in producing cutting tools that combine innovation, quality, and performance. The BLMP0603R-M is designed to deliver unmatched results in both roughing and finishing operations, ensuring higher productivity and reduced machining costs. This article provides a detailed overview of the product, covering its advantages, technical specifications, performance parameters, applications, features, precautions, and innovation highlights.

1. Advantages of BLMP0603R-M Carbide Inserts

Carbide inserts like the BLMP0603R-M are developed to meet the increasing demands of modern machining centers and CNC milling machines. Here are the core advantages:

High Wear Resistance

Manufactured from premium tungsten carbide with cobalt binder, the insert ensures maximum resistance against abrasive wear.

This property is particularly critical in high-speed milling operations where cutting temperatures rise significantly.

Extended Tool Life

Thanks to advanced PVD/CVD coatings (e.g., TiAlN, AlTiN, or multilayer coatings), the insert maintains hardness even at elevated temperatures.

Users benefit from longer tool life, reducing downtime for insert changes.

High Cutting Efficiency

The optimized geometry of BLMP0603R-M enables smooth chip evacuation and reduced cutting resistance.

This translates to higher feed rates and better material removal efficiency.

Versatility Across Materials

Suitable for machining steel, stainless steel, cast iron, hardened alloys, and non-ferrous metals.

One insert can handle a variety of jobs, reducing inventory requirements.

Dimensional Accuracy & Surface Finish

Designed for precision milling, the insert produces excellent surface finishes and dimensional accuracy, critical in aerospace and mold-making industries.

2. Performance Analysis & Technical Parameters

The designation BLMP0603R-M is not just a random code but a technical standard that reveals key insert specifications:

B – Insert shape designation

L – Relief angle

M – Tolerance class (medium)

P – Insert type (specific cutting geometry)

0603 – Size code

06 → Insert length/size (approx. 6 mm)

03 → Insert thickness (approx. 3 mm)

R – Corner radius (R) for smooth cutting and durability

M – Chipbreaker design (Medium cutting conditions)

Key Numerical Parameters

Insert Length: ~6.0 mm

Insert Thickness: ~3.0 mm

Corner Radius: typically 0.5–0.8 mm

Cutting Depth (ap): Up to 3.0 mm depending on toolholder and workpiece material

Feed Rate (fz): 0.05–0.25 mm/tooth (application-dependent)

Cutting Speed (Vc): 100–300 m/min for steel, lower for stainless/cast iron

These parameters allow machinists to fine-tune their milling operations based on workpiece requirements.

3. Application Scenarios

The BLMP0603R-M insert is widely used across industries requiring high-performance milling solutions:

Automotive Industry

Machining engine components, transmission housings, and brake system parts.

High accuracy ensures better assembly fit and long-lasting parts.

Aerospace Industry

Milling titanium alloys, Inconel, and stainless steels used in aircraft engine parts.

The insert’s heat resistance ensures stable cutting under extreme conditions.

Mold & Die Industry

Used in finishing operations of molds where surface quality is critical.

Capable of machining hardened tool steels with minimal wear.

General Engineering

Suitable for machining shafts, plates, flanges, and custom mechanical components.

Handles both roughing and finishing in a single setup.

Energy & Heavy Machinery

Used in manufacturing turbine components, oil & gas equipment, and mining machinery.

Resistant to heavy-duty cutting forces and vibration.

4. Key Features

Optimized Chipbreaker Design: Ensures smooth chip evacuation, preventing tool clogging and protecting workpiece surface quality.

Tough Substrate: Made from ultra-fine grain carbide, balancing hardness and toughness for superior cutting stability.

Coating Options:

TiAlN: Excellent heat resistance and oxidation resistance.

AlTiN: Superior toughness for dry machining.

Multilayer Coating: Balanced wear resistance for a wide range of applications.

High Stability: Insert geometry minimizes vibration, improving toolholder life and spindle stability.

Compatibility: Designed to fit common indexable milling cutters, making it versatile for multiple setups.

5. Precautions for Use

To maximize the performance of BLMP0603R-M inserts, machinists should observe the following precautions:

Correct Insert Selection

Choose the appropriate corner radius and chipbreaker based on the material and cutting conditions.

Proper Toolholder Clamping

Ensure the insert is securely mounted to prevent vibration and insert breakage.

Cutting Parameters

Avoid exceeding the recommended cutting depth and feed rate. Overloading leads to premature wear.

Coolant Use

For stainless steel and high-temperature alloys, apply coolant to prevent overheating.

For cast iron and dry machining applications, minimal coolant or dry cutting may be preferable.

Regular Inspection

Inspect inserts after each cycle for flank wear, chipping, or crater wear.

Replace inserts before failure to protect the workpiece and toolholder.

6. Technical Innovations & Patent Highlights

Our BLMP0603R-M carbide inserts integrate several technological advancements:

Nano-Coating Technology:

Increases hardness at high temperatures, prolonging tool life by 20–40%.

Advanced Edge Preparation:

Controlled honing and polishing improve sharpness and reduce cutting resistance.

Multi-Layer Gradient Substrate:

Tougher core with harder outer layer resists both fracture and wear.

Patent Chipbreaker Design:

Unique groove patterns reduce cutting forces and enhance chip flow.

Sustainable Manufacturing:

Inserts are produced with recycling and green carbide technology, reducing environmental impact.

7. Why Choose Our Carbide Inserts?

As a dedicated hard alloy manufacturer, we combine R&D strength, strict quality control, and customer-focused solutions to deliver cutting tools that outperform generic inserts. Our BLMP0603R-M is trusted by machining shops worldwide because it offers:

Competitive pricing with premium quality

Custom solutions (OEM/ODM available)

Consistency across large-volume production

Compliance with ISO standards

Proven performance in demanding industries

Conclusion

The BLMP0603R-M carbide milling insert is a high-performance cutting tool engineered for efficiency, durability, and precision. With its superior wear resistance, advanced coatings, optimized chipbreaker design, and wide application range, it has become an essential solution for modern machining industries.

By choosing our carbide inserts, manufacturers can achieve:

Higher productivity

Lower machining costs

Consistent surface quality

Extended tool life

Whether you are in automotive, aerospace, mold-making, or heavy machinery, the BLMP0603R-M delivers the cutting-edge performance required to stay competitive in today’s fast-paced manufacturing world.

Previous page

Use equipment

CNC machining centre

CNC machine tools

Carved machine

Factory Board

Factory Board

Factory Board

Factory Board

Factory Board

Recommended products

FAQ

2025-05-29

The naming conventions for turning inserts generally follow international standards (such as ISO standards). The model number consists of a series of letters and numbers, each character representing different geometric parameters or functional characteristics, such as the naming convention for the TNMG160404R-PV turning insert from Lizhou.

2025-05-26

What types of end mills are there?

Materials can be processed according to different types of end mills, categorized by the types of milling tools, including flat end mills, ball end mills, radius end mills, chamfer end mills, and end mills with chip breakers.

2025-05-23

PCD milling cutter is a polycrystalline diamond (PCD) milling cutter, which has a wide range of applications in the field of machining.

2025-05-08

End mill for machining aluminum materials

Many customers have told us that ordinary end mills frequently stick when machining aluminum, and the accumulation of chips affects the accuracy, so they always change the tools. LIZHOU editor suggests that coated end mills are not recommended for aluminum materials, because some coatings contain aluminum elements. Therefore, it is better to choose uncoated end mills when selecting end mills for machining aluminum materials.