Product

APKT1705 square shoulder milling cutter series

China Lizhou Hard Alloy Source Factory

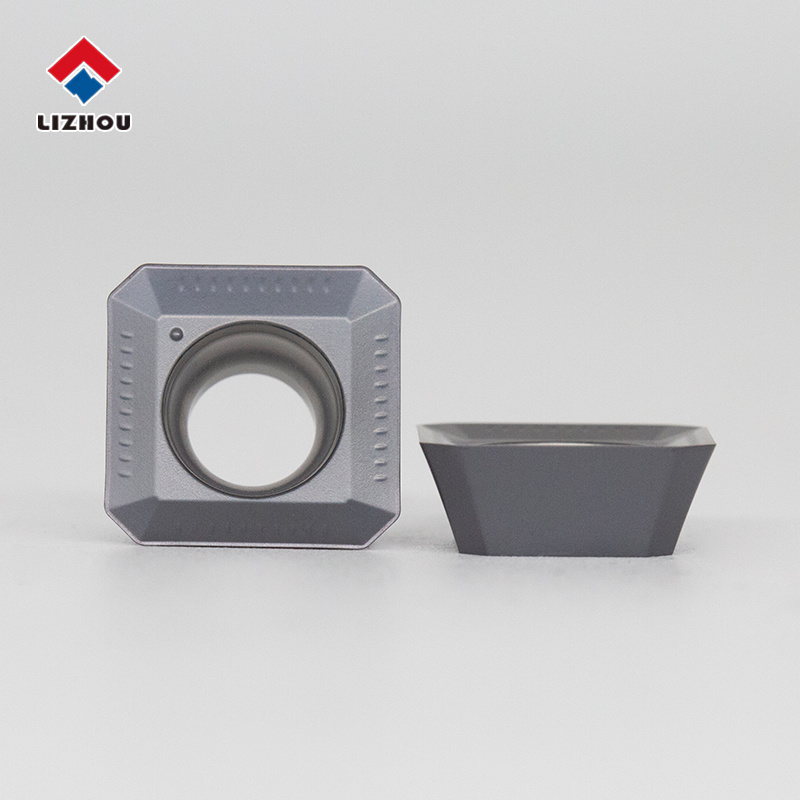

Product Name: milling insert

Coating : PVD

Material:Tungsten steel

Classification :

Milling insert

keyword:

lizhou

APKT170508R-EM Carbide Milling Insert: Comprehensive Guide to Performance, Applications, and Innovations

Introduction

The APKT170508R-EM is a high-performance carbide milling insert designed for precision machining across industries such as automotive, aerospace, mold-making, and general metalworking. Manufactured with advanced tungsten carbide substrate and optimized coating technologies, this insert ensures durability, heat resistance, and excellent cutting performance.

As part of our hard alloy (cemented carbide) tooling solutions, the APKT170508R-EM has become a preferred choice among machinists and engineers who require high efficiency, stability, and long tool life during milling operations. In this article, we will explore the product’s advantages, technical parameters, performance analysis, application fields, usage guidelines, and innovation aspects.

1. Understanding the Naming System: APKT170508R-EM

The product code APKT170508R-EM follows the ISO standard nomenclature used in carbide inserts. Each letter and number provides key insights into its geometry and usage:

A – Insert shape: 85° parallelogram shape

P – Relief angle: 11° clearance

K – Tolerance class: molded tolerance with precision finish

T – Type of insert: single-sided with a hole

17 – Insert size (length = 17 mm nominal dimension)

05 – Insert thickness (5.0 mm)

08 – Cutting edge length (8.0 mm)

R – Corner radius (in this case, R = 0.8 mm)

EM – Chipbreaker style: optimized for medium cutting operations

This system makes the APKT170508R-EM a versatile and reliable insert suitable for a wide range of milling applications.

2. Advantages of Carbide Inserts in Milling Operations

As a cemented carbide manufacturer, we utilize the highest quality raw materials and precision grinding processes to produce inserts like the APKT170508R-EM. The advantages include:

Exceptional Hardness and Wear Resistance

Made from tungsten carbide, hardness levels reach above 90 HRA.

Ensures excellent resistance against abrasive wear.

High Red Hardness

Carbide maintains cutting performance even at elevated temperatures (up to 1000°C).

Suitable for high-speed and dry machining.

Long Tool Life

Optimized PVD or CVD coatings enhance tool lifespan.

Reduces downtime for tool changes, improving productivity.

Precision and Stability

Tight tolerance guarantees dimensional accuracy.

Stable insert clamping reduces vibration and ensures better surface finish.

Cost-Effectiveness

Though the initial cost of carbide is higher than HSS, the tool’s extended life and efficiency result in a lower cost per part.

3. Performance Analysis of APKT170508R-EM

3.1 Cutting Efficiency

The APKT170508R-EM insert is designed for high material removal rates with reduced cutting forces. Its chipbreaker geometry allows smoother chip evacuation, preventing chip clogging during continuous cutting.

3.2 Versatility in Materials

Steel (P-class): Stable performance under medium to high cutting speeds.

Cast Iron (K-class): Excellent wear resistance against abrasive materials.

Stainless Steel (M-class): Coating prevents built-up edge formation.

Non-ferrous alloys (N-class): Capable of machining aluminum and copper alloys with high precision.

3.3 Surface Quality

The optimized rake angle and precision-ground edges reduce cutting pressure, improving surface roughness (Ra 0.8–1.6 achievable).

3.4 Tool Life & Heat Resistance

With multilayer coatings (TiAlN, AlTiN, or CVD TiCN/Al2O3/TiN), the APKT170508R-EM maintains thermal stability and resists crater wear, ensuring longer tool life.

4. Applications of APKT170508R-EM

The APKT170508R-EM is widely used in indexable milling cutters, including:

Face milling cutters

End mills

Shoulder milling cutters

Chamfering cutters

Copy milling cutters

Industry Applications:

Automotive – Cylinder blocks, engine housings, gearboxes

Aerospace – Titanium alloy components, turbine housings, aluminum structures

Die and Mold – Tool steels, hardened steels, cavity finishing

General Engineering – Flanges, shafts, machine bases

5. Key Features of APKT170508R-EM

Universal application: One insert can cover multiple cutting conditions.

Optimized chipbreaker design: Reduces cutting resistance, enhances chip evacuation.

Multi-layer coating: Improves tool hardness and oxidation resistance.

Precision-ground edges: Prevents microchipping and improves part quality.

Compatibility: Fits multiple milling cutter bodies (ISO-standard insert pockets).

6. Precautions and Best Practices

To maximize the performance of APKT170508R-EM inserts, machinists should observe the following:

Correct Cutting Parameters

Recommended cutting speed: 180–300 m/min (steel)

Feed rate: 0.1–0.3 mm/tooth

Depth of cut: 0.5–4.0 mm (depending on setup)

Proper Clamping

Ensure insert pocket is clean and free of debris.

Apply correct torque to screws to prevent insert breakage.

Coolant Usage

For steels and stainless steels, coolant improves tool life.

For cast iron, dry cutting is often recommended.

Avoid Interrupted Cuts at High Speed

Can cause chipping or premature failure of carbide inserts.

Regular Inspection

Replace inserts before catastrophic failure to protect cutter body.

7. Technical Innovations & Patents

Our carbide inserts integrate proprietary technologies that differentiate them from conventional products:

Nano-structured Coatings: Improved adhesion and hardness for longer tool life.

Advanced Powder Metallurgy: Ensures uniform carbide grain size (0.5–0.8 µm).

Patented Chipbreaker Design: Reduces vibration and enhances chip evacuation.

Surface Treatment Technology: Provides smoother coating layers, reducing friction.

These innovations allow the APKT170508R-EM to achieve 30–50% higher performance compared to standard milling inserts.

8. Why Choose Our Carbide Inserts?

As a professional hard alloy manufacturer, we provide:

OEM/ODM customization for different milling applications.

Strict quality control from raw materials to finished inserts.

Competitive pricing with stable supply.

Technical support for parameter optimization.

Conclusion

The APKT170508R-EM carbide milling insert represents the perfect combination of hardness, toughness, and innovation. With superior wear resistance, optimized chipbreaker geometry, and multi-layer coatings, it offers unmatched performance in various milling operations.

By selecting APKT170508R-EM, manufacturers can improve productivity, cost efficiency, and machining precision. Whether you are in automotive, aerospace, mold-making, or general engineering, this insert delivers reliable results.

Frequently Asked Questions

Q: 1. Are you a trading company or a manufacturer?

A: Our company is a professional manufacturer with 32 years of industry experience.

Q: 2. Do you provide samples? Is it free or extra?

A: Yes, we can provide free samples for testing support; customers only need to pay for the sample shipping cost.

Q: 3. Can you produce special cemented carbide tools?

A: Yes, we can. We have our own professional R&D team and can produce according to your drawings or samples.

Q: 4. What is your minimum order quantity?

A: 100 pieces.

Previous page

Next page

Use equipment

CNC machining centre

CNC machine tools

Carved machine

Factory Board

Factory Board

Factory Board

Factory Board

Factory Board

Recommended products

FAQ

2025-05-29

The naming conventions for turning inserts generally follow international standards (such as ISO standards). The model number consists of a series of letters and numbers, each character representing different geometric parameters or functional characteristics, such as the naming convention for the TNMG160404R-PV turning insert from Lizhou.

2025-05-26

What types of end mills are there?

Materials can be processed according to different types of end mills, categorized by the types of milling tools, including flat end mills, ball end mills, radius end mills, chamfer end mills, and end mills with chip breakers.

2025-05-23

PCD milling cutter is a polycrystalline diamond (PCD) milling cutter, which has a wide range of applications in the field of machining.

2025-05-08

End mill for machining aluminum materials

Many customers have told us that ordinary end mills frequently stick when machining aluminum, and the accumulation of chips affects the accuracy, so they always change the tools. LIZHOU editor suggests that coated end mills are not recommended for aluminum materials, because some coatings contain aluminum elements. Therefore, it is better to choose uncoated end mills when selecting end mills for machining aluminum materials.