Blog

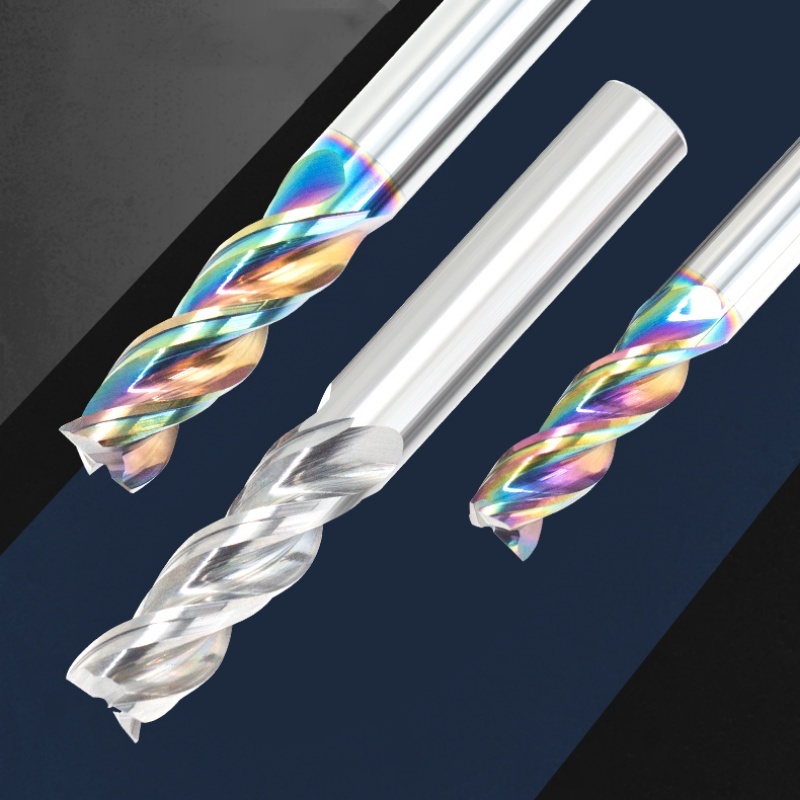

End mill for machining aluminum materials

End mills for machining aluminum materials:

Many customers tell us: Ordinary end mills frequently stick when machining aluminum, and the accumulation of chips affects the accuracy, so they always change tools.

Lizhou editor suggests that end mills for aluminum materials are not recommended to use coated end mills. Some coatings contain aluminum elements, so it is better to choose uncoated end mills when choosing end mills for machining aluminum materials.

I. Core advantages and applicable scenarios of uncoated end mills

- Cost advantage : Saves the coating process, and the price is lower than coated tools 30%-50%

- Extremely sharp cutting edge : No coating interference, suitable for processing ultra-soft aluminum (such as 1050/1060 )

- Fast regrinding and reuse : After wear, the cutting edge can be directly sharpened without removing the coating

Suitable working conditions :

Short-term small-batch production

Aluminum parts trial production or prototype processing

Surface finish requirements are not high ( Ra > 1.6μm )

Recommended intelligent chip removal system in end mills:

Front end 15° Spiral angle strong chip breaking

Middle section 25° Spiral angle accelerates chip removal

End 35° Spiral angle prevents secondary scratching

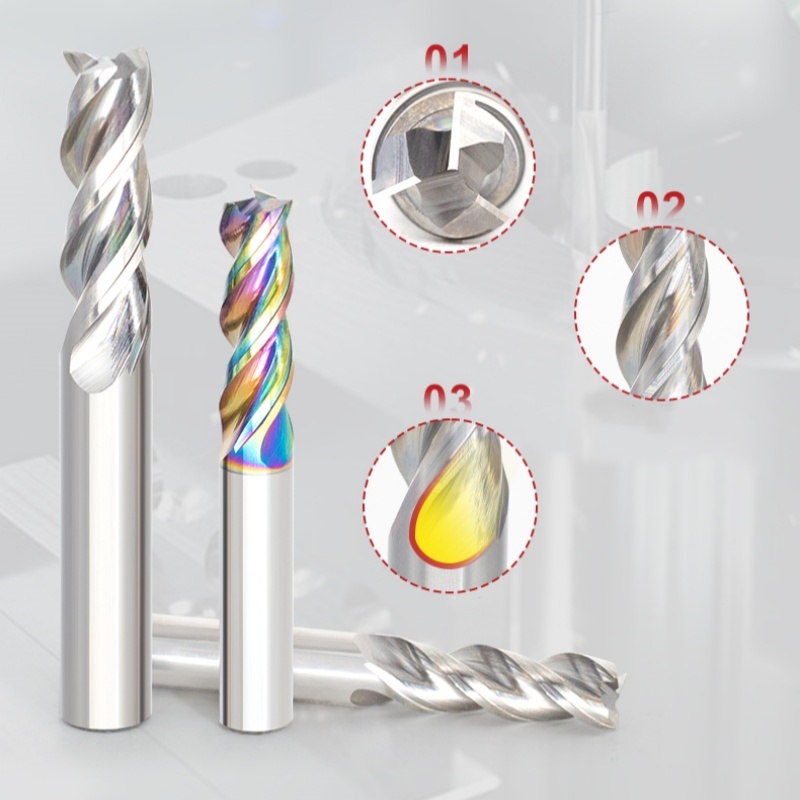

II. Selection points for uncoated end mills

Key parameters

|

Recommended value

|

Function

|

|---|---|---|

Material

|

Ultra-fine grain cemented carbide (grain size ≤0.5μm )

|

Improve cutting edge sharpness and anti-chipping performance

|

Rake angle

|

18°-25°

|

Reduce cutting resistance and suppress built-up edge

|

Spiral angle

|

45°-60° (High helix)

|

Forced chip removal, reduce sticking

|

Number of blades

|

2 Blades (roughing) |

Balance cutting efficiency and surface quality

|

III. Why choose Lizhou cemented carbide:

Manufacturing strength: German Sauer Five-axis grinding machine + Swiss Agie Slow wire EDM, cutting edge runout ≤0.005mm

Scenario verification: Covers mobile phone CNC Machining, aerospace components, automotive die castings, etc. 12 Sub-fields

Recommended aluminum end mills:

IV. Usage tips for uncoated end mills

1. Cooling scheme :

Air cooling is required : Air pressure ≥6bar ,Directly blow to the cutting point

Optional cutting fluid : Water-soluble emulsion (concentration 5%-8% ), Oily liquid is prohibited (easy to stick chips)

2. Parameter optimization (With φ6mm tool as an example):

Processing type

|

Speed ( RPM )

|

Feed ( mm/min )

|

Cutting depth (axial)

|

|---|---|---|---|

Roughing

|

15,000-20,000

|

1,200-1,800

|

0.8-1.2×D

|

Fine machining

|

20,000-25,000

|

600-1,000

|

0.1-0.3×D

|

3. Anti-sticking knife measures :

Per machining 30 Minutes used WD-40 Spray cleaning blade

Fine machining uses a "high speed + low feed" strategy (such as 25,000RPM + 800mm/min )

Summary:

Aluminum end mills and milling inserts generally do not use coatings. You can also contact Lizhou Cemented Carbide for more details on aluminum milling inserts.

previous page

Recommended products

undefined