Product

BNM ball-nose end mill

China Lizhou Hard Alloy Source Factory

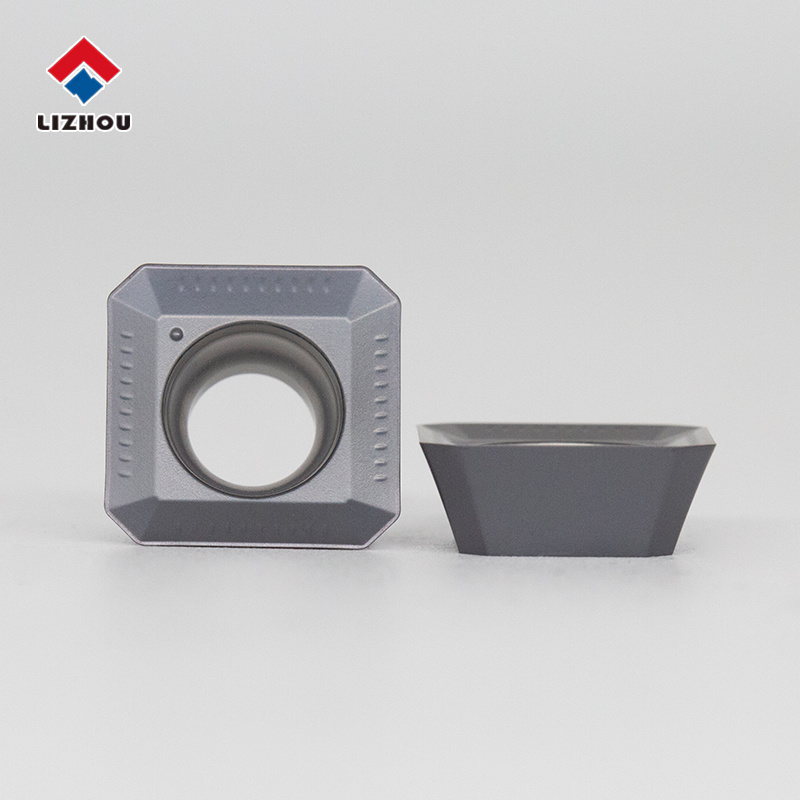

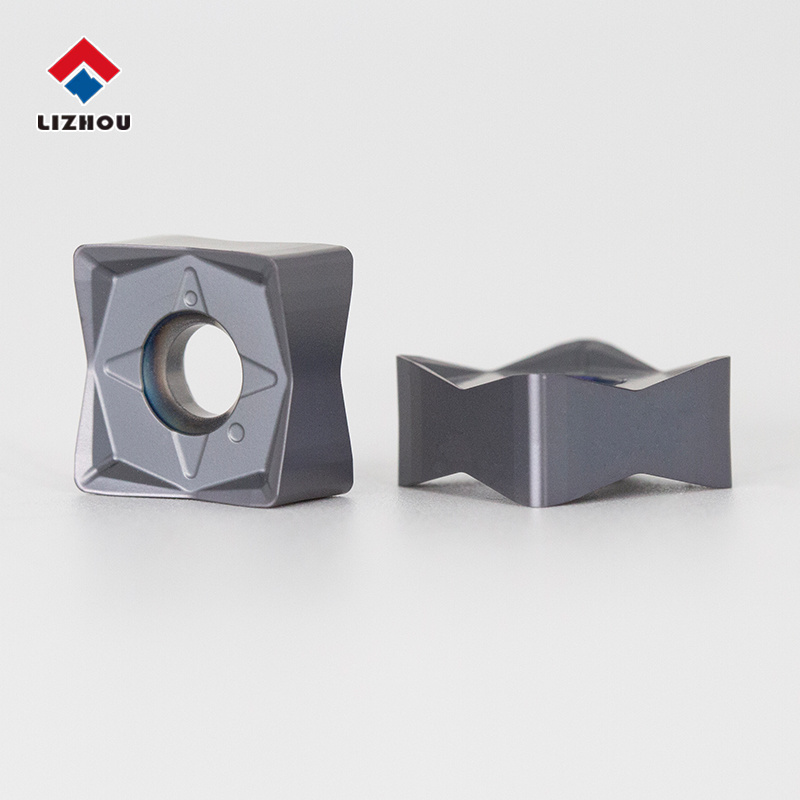

Product Name: milling insert

Coating : CVD

Material:Tungsten steel

Classification :

Milling insert

keyword:

lizhou

BNM100 Carbide Milling Insert – Advanced Performance for High-Precision Machining

Introduction

The BNM100 carbide milling insert is one of the flagship products developed by our company, a professional cemented carbide manufacturer with years of expertise in precision cutting tools. Designed for superior toughness, excellent wear resistance, and extended tool life, the BNM100 insert delivers optimal results in both high-speed and heavy-duty milling applications.

Whether used in automotive, aerospace, mold manufacturing, or general engineering, this insert provides the perfect balance between durability and precision.

This article provides a comprehensive overview of the advantages, specifications, features, applications, technical innovations, and operational guidelines of the BNM100 milling insert.

1. The Advantages of Carbide Inserts in Modern Milling

Carbide inserts such as the BNM100 are made from tungsten carbide (WC) combined with cobalt (Co) or other metallic binders, sintered under high temperature and pressure. Compared to traditional high-speed steel (HSS), carbide inserts offer:

High Hardness and Wear Resistance – Capable of cutting hardened steels, cast iron, stainless steel, and superalloys.

Superior Heat Resistance – Can withstand high cutting temperatures without losing hardness.

Extended Tool Life – Reduced downtime and lower tool change frequency.

Consistent Performance – Maintains precision and accuracy in long production runs.

Cost-Effectiveness – Although the initial investment is higher than HSS, the long-term savings in efficiency and productivity outweigh the cost.

2. Breaking Down the BNM100 Code

Every insert designation represents important geometry and application details. While BNM100 is the model name, it follows ISO-standardized coding rules. Here’s how to understand the parameters:

B – Insert shape (often indicates a round or specific edge design optimized for multi-directional milling).

N – Relief angle (usually 0°, providing high edge strength and longer life).

M – Tolerance class (medium precision, suitable for general and finishing operations).

100 – Grade designation (specific to coating and substrate combination).

This structured naming system ensures customers and engineers can quickly identify the insert’s geometry, precision level, and material properties.

3. Material Grade and Coating Technology

The BNM100 insert uses advanced nano-composite PVD/CVD coatings combined with an ultra-fine carbide substrate.

Substrate: Fine-grain tungsten carbide ensures excellent toughness and fracture resistance.

Coating Options:

TiAlN (Titanium Aluminum Nitride) – Provides superior oxidation resistance for high-speed cutting.

AlTiN (Aluminum Titanium Nitride) – Ideal for dry milling at elevated temperatures.

Multi-layer CVD Coatings – Designed for heavy-duty applications with better wear resistance.

This combination allows the BNM100 to perform exceptionally in high-speed, dry, and semi-dry cutting environments, while also maintaining long tool life under coolant-assisted machining.

4. Application Scenarios

The BNM100 milling insert is highly versatile and supports various machining operations:

Face Milling – Ensures smooth surface finishes with stable chip evacuation.

Shoulder Milling – Provides excellent wall accuracy and minimal vibration.

Slot Milling – Maintains cutting precision in narrow slots and grooves.

Profile Milling – Handles complex 3D contours and curved surfaces effectively.

High-Speed Machining (HSM) – Perfect for aerospace alloys and hardened tool steels.

Industries Served

Automotive Manufacturing – Cylinder heads, transmission housings, and brake components.

Aerospace – Turbine blades, titanium components, and high-strength alloys.

Mold & Die Industry – Precision cavity milling and surface finishing.

General Engineering – Steel fabrication, mechanical parts, and machine components.

5. Key Features of BNM100

Optimized Cutting Edge – Reduces cutting force and vibration for stable performance.

High Surface Finish Quality – Achieves smoother surfaces, reducing secondary finishing work.

Excellent Tool Life – Resistant to abrasion and thermal cracking.

Flexible Machining – Capable of both roughing and finishing in a single tool setup.

Chip Control – Special geometry ensures efficient chip breaking, preventing tool jamming.

6. Performance Benefits

High Productivity – Allows for faster feed rates and higher cutting speeds.

Lower Machining Costs – Reduced tool replacement frequency leads to cost savings.

Energy Efficiency – Smooth cutting reduces machine load and power consumption.

Dimensional Accuracy – Tight tolerances ensure consistent part quality.

7. Operational Considerations & Best Practices

When using BNM100 carbide milling inserts, following proper machining guidelines is essential:

Cutting Speed (Vc): Adjust based on material (e.g., 200–400 m/min for steels, 150–300 m/min for cast iron).

Feed Rate (fz): Optimize depending on insert size and workpiece hardness.

Depth of Cut (ap): Ensure balance between tool load and desired material removal rate.

Coolant Usage: Suitable for both dry and wet cutting; use coolant for heat-sensitive alloys.

Tool Holder Compatibility: Ensure secure clamping for maximum rigidity.

8. Technical Innovations and Patents

The BNM100 incorporates several innovations:

Nano-Coating Technology – Extends tool life by reducing friction and wear.

Micro-Geometry Optimization – Special edge preparation minimizes chipping.

Anti-Vibration Design – Improves stability in high-speed milling.

Proprietary Powder Metallurgy – Ensures uniform carbide grain size for balanced hardness and toughness.

Our R&D team continuously works on patented geometries and coating processes, ensuring the BNM100 remains competitive in global markets.

9. Why Choose Our BNM100 Carbide Insert?

As a professional hard alloy manufacturer, we provide not only premium-grade inserts but also technical support, OEM/ODM services, and customized solutions for different industries.

High-quality raw materials sourced from reliable suppliers.

Strict quality control from powder metallurgy to final inspection.

Global compatibility with major milling systems (ISO/ANSI standard).

Competitive pricing with direct factory supply.

Fast delivery and flexible order quantities.

Conclusion

The BNM100 carbide milling insert stands as a reliable and high-performance solution for modern machining industries. With its advanced substrate, innovative coating technology, and optimized geometry, it ensures long tool life, superior surface finish, and cost-efficient productivity. Whether you are working with steel, cast iron, stainless steel, titanium, or hardened alloys, the BNM100 is engineered to deliver consistent results across diverse milling applications.

By choosing BNM100, you invest in efficiency, reliability, and innovation, ensuring your manufacturing operations remain competitive in today’s demanding global markets.

Frequently Asked Questions

Q: 1. Are you a trading company or a manufacturer?

A: Our company is a professional manufacturer with over 32 years of experience in this field.

Q: 2. Do you provide samples? Is it free or extra?

A: Yes, we can provide free samples for testing support; customers only need to pay for the sample shipping cost.

Q: 3. Can you produce special cemented carbide tools?

A: Yes, we can. We have our own professional R&D team and can produce according to your drawings or samples.

Q: 4. What is your minimum order quantity?

A: 100 pieces.

Previous page

Next page

Use equipment

CNC machining centre

CNC machine tools

Carved machine

Factory Board

Factory Board

Factory Board

Factory Board

Factory Board

Recommended products

FAQ

2025-05-29

The naming conventions for turning inserts generally follow international standards (such as ISO standards). The model number consists of a series of letters and numbers, each character representing different geometric parameters or functional characteristics, such as the naming convention for the TNMG160404R-PV turning insert from Lizhou.

2025-05-26

What types of end mills are there?

Materials can be processed according to different types of end mills, categorized by the types of milling tools, including flat end mills, ball end mills, radius end mills, chamfer end mills, and end mills with chip breakers.

2025-05-23

PCD milling cutter is a polycrystalline diamond (PCD) milling cutter, which has a wide range of applications in the field of machining.

2025-05-08

End mill for machining aluminum materials

Many customers have told us that ordinary end mills frequently stick when machining aluminum, and the accumulation of chips affects the accuracy, so they always change the tools. LIZHOU editor suggests that coated end mills are not recommended for aluminum materials, because some coatings contain aluminum elements. Therefore, it is better to choose uncoated end mills when selecting end mills for machining aluminum materials.