Blog

What is a PCD milling cutter?

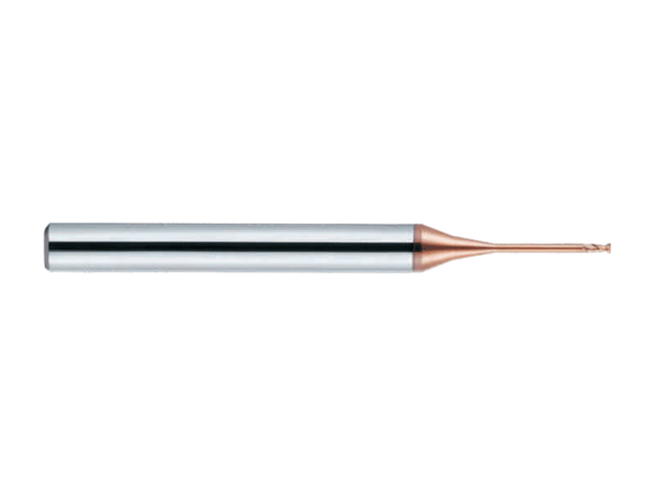

What is PCD end mill?

PCD An end mill is a polycrystalline diamond ( Polycrystalline Diamond ) end mill which has a wide range of applications in mechanical machining.

PCD Characteristics of end mills

- High hardness: PCD It is a polycrystalline material made by sintering diamond powder at high temperatures. Its hardness is extremely high, approaching that of natural diamond and far exceeding that of ordinary tool materials such as cemented carbide. This allows PCD effective cutting of various high-hardness materials

- Good thermal conductivity: Diamond has good thermal conductivity, PCD end mills can quickly conduct cutting heat away, reducing the temperature of the tool and workpiece, reducing thermal deformation and thermal damage, which helps improve processing accuracy and surface quality.

PCD What materials can end mills process?

Non-ferrous metals: such as aluminum alloys, copper alloys

Non-metallic hard and brittle materials: such as cemented carbide, ceramic materials, optical glass

Composite materials: fiber-reinforced composite materials, particle-reinforced composite materials

PCD Disadvantages of end mills:

- Higher cost

- Not suitable for processing iron-based materials

Performance advantages

High-precision machining: PCD End mills have high edge precision and can achieve micron-level machining accuracy, meeting the processing requirements of various precision parts

High-efficiency cutting: Due to PCD the high hardness and wear resistance of the material, the cutting speed and feed rate of the tool can be significantly increased to shorten the processing time and improve processing efficiency

Long tool life: PCD End mills have good wear resistance and long tool life, reducing the number of tool changes and downtime, and improving production efficiency.

previous page

Recommended products