Product

FAQ

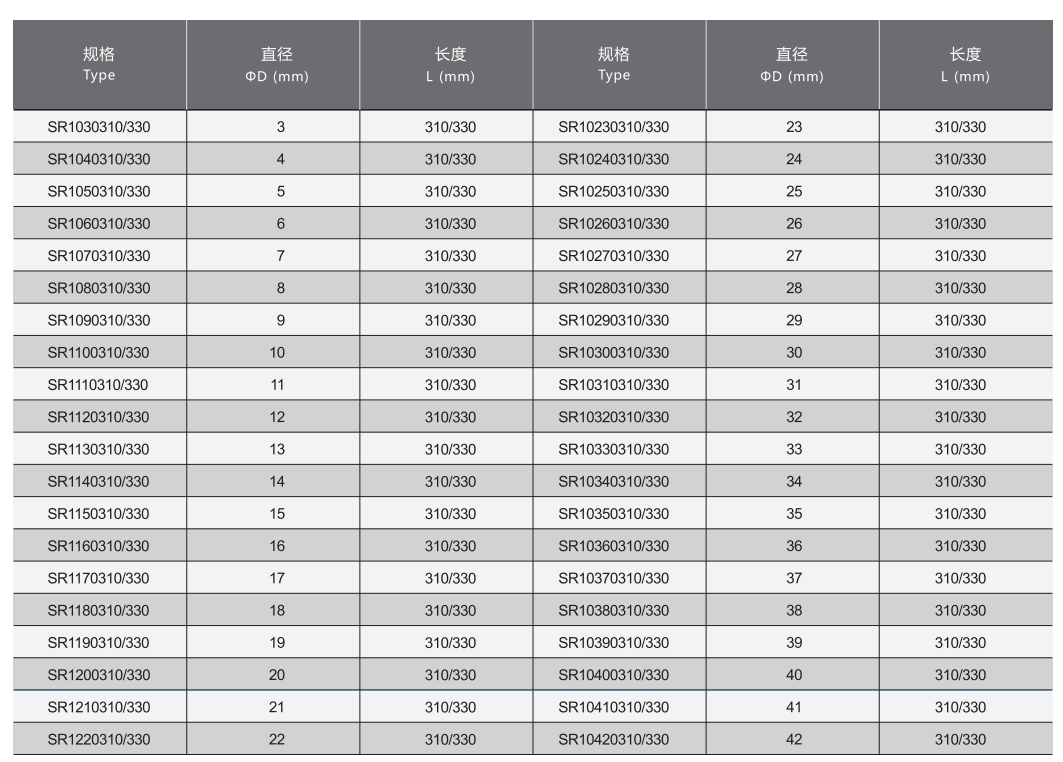

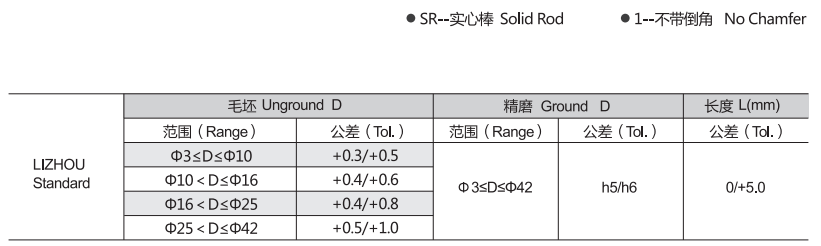

LBC12S grade metric solid round bar

China Lizhou Hard Alloy Source Factory

Grade:LBC12S

Classification :

Carbide Rod

keyword:

lizhou

LBC12s Tungsten Carbide Rods – Technical Introduction and Application Insights

Introduction

In the world of precision machining, cutting tools, and wear-resistant components, tungsten carbide rods play an irreplaceable role. Among the different grades of carbide available, LBC12s stands out as a highly reliable grade for producing high-performance cutting tools and industrial parts. Manufactured by LIZHOU Carbide Factory, the LBC12s tungsten carbide rod is engineered with optimized composition, advanced grain control, and superior mechanical properties.

This article provides a comprehensive overview of LBC12s carbide rods, including performance advantages, detailed technical parameters, application scenarios, features, precautions, and potential innovations. Whether you are a tool manufacturer, distributor, or end-user, this guide will help you better understand why LBC12s is a preferred grade in the global market.

1、Composition and Key Technical Parameters

Grade: LBC12S

Cobalt Content: 12%

Tungsten Carbide Content: 88%

Grain Size: 0.6μm

Density: 14.15g/cm3

Vickers Hardness: 1600Kg/mm2

Rockwell Hardness: 91.5

Bending Strength: 4400N/mm2

2、Performance Advantages of LBC12s Carbide Rods

Superior Wear Resistance

With a hardness of 91.5 HRA and ultrafine grains, LBC12s offers excellent wear resistance, reducing tool replacement frequency and lowering production costs.

High Strength and Toughness

The combination of 12% cobalt and a TRS of 4400 MPa makes LBC12s extremely strong. It withstands heavy cutting forces and impact loads, reducing tool breakage risks.

Thermal Stability

Carbide rods must endure high cutting temperatures. LBC12s retains hardness and edge stability under elevated temperatures, ensuring consistent performance in high-speed machining.

Dimensional Stability

The uniform microstructure guarantees minimal deformation, which is critical for producing precision cutting tools such as drills, reamers, and end mills.

Versatility

Its balanced properties make it suitable for multiple machining applications, from steel and stainless steel to cast iron and titanium alloys.

3、pplication Scenarios

The LBC12s tungsten carbide rod is widely used across industries due to its versatility and performance. Below are its primary application areas:

1. Cutting Tools Manufacturing

End Mills: For milling hardened steels, stainless steels, and non-ferrous metals.

Drills: For precision drilling with high feed rates and long tool life.

Reamers: For finishing operations requiring tight tolerances.

Taps: For threading applications where wear resistance is essential.

2. Wear-Resistant Components

Valve components in the oil & gas industry.

Nozzles in sandblasting and spraying equipment.

Punches and dies for precision stamping.

3. Aerospace and Automotive Industry

Machining high-strength alloys used in engines and structural components.

Cutting tools for producing precision automotive parts.

4. Medical and Electronics Applications

Micro-drilling tools for printed circuit boards (PCBs).

Precision cutting instruments in surgical equipment.

4、Features and Characteristics

Micro-Grain Technology: 0.6 μm ultrafine structure improves hardness without sacrificing toughness.

Uniformity in Quality: Controlled manufacturing process ensures consistent properties across batches.

High-Polish Capability: Smooth surface finish reduces friction and improves cutting efficiency.

Customization Available: Can be supplied as solid rods, coolant hole rods, or ground rods according to customer requirements.

5、Precautions and Best Practices

While LBC12s rods are robust, users should follow best practices to maximize tool life and ensure safety:

Proper Cutting Parameters: Avoid exceeding recommended cutting speeds and feed rates to prevent premature wear.

Coolant Usage: Use appropriate cutting fluids to control temperature and reduce thermal shock.

Grinding Considerations: Use diamond grinding wheels for re-sharpening to maintain edge precision.

Avoid Impact Loads: Even though the rods are tough, sudden impacts or incorrect tool clamping can cause breakage.

Storage and Handling: Store rods in a dry, clean environment to prevent corrosion of the cobalt binder.

6、Technological and Patent Innovations

LIZHOU Carbide Factory has invested in powder metallurgy innovations, ensuring precise grain control and homogeneous cobalt distribution. Some of the innovative aspects include:

Nano Powder Preparation: Enhances uniformity and reduces structural defects.

HIP (Hot Isostatic Pressing) Technology: Improves density and eliminates internal porosity, resulting in stronger rods.

Coolant Hole Technology: Special rod designs with internal cooling channels improve heat dissipation during high-speed cutting.

Surface Treatment Patents: Coating compatibility is enhanced by ultra-clean surface preparation, extending tool coating life.、

7、Why Choose LIZHOU LBC12s Carbide Rods?

Factory-Direct Supply: Ensures competitive pricing and stable quality.

Global Export Experience: Trusted by customers in Asia, Europe, and the Americas.

Custom Engineering: Tailored solutions for different cutting applications.

Strict Quality Control: Each batch undergoes density, hardness, and TRS testing.

Technical Support: Professional guidance for tool design and parameter optimization.

Conclusion

The LBC12s tungsten carbide rod represents a perfect balance of hardness, strength, and toughness, making it a versatile choice for tool manufacturers worldwide. With a cobalt content of 12%, hardness of 91.5 HRA, TRS of 4400 MPa, and ultrafine grain size of 0.6 μm, it is designed to meet the growing demand for precision and durability in modern machining.

From cutting tools to wear-resistant components, LBC12s delivers excellent performance, backed by advanced manufacturing technologies and strict quality standards. For companies seeking reliable carbide rods that enhance tool life, reduce costs, and improve machining quality, LBC12s is a proven solution.

Next page

Use equipment

CNC machining centre

CNC machine tools

Carved machine

Factory Board

Factory Board

Factory Board

Factory Board

Factory Board

Recommended products

FAQ

2025-12-12

Lizhou Indexable U-Drill Series | High-Speed Drilling Solution for Large-Hole U-Drills

The Lizhou U-drill series is suitable for large-hole drilling in a variety of materials, including steel, stainless steel, alloy steel, and titanium alloys. It offers two structural types: square U-drills and peach-shaped U-drills. These drills combine rigidity, centering accuracy, and chip-removal efficiency, enabling multi-process machining that includes drilling, boring, and chamfering. Featuring high-quality carbide inserts and a stable tool body design, this series ensures more efficient batch drilling at lower costs.

2025-12-12

Lizhou Carbide Turning Inserts Series | Cemented Carbide CNC Turning Solutions

The Lizhou carbide turning blade series specializes in CNC turning applications using cemented carbide, covering common machining operations such as external cylindrical turning, end-face turning, roughing, and finishing. We offer diamond-shaped blades, square blades, triangular blades, peach-shaped blades, and peel-off blades, each tailored with specific grades and flute geometries for materials including cast iron, steel, stainless steel, high-hardness steel, and copper and aluminum. These blades help workshops enhance tool life and improve machining stability.

2025-12-12

Lizhou Threaded Blade Series | High-Precision, Stable Thread-Machining Solution

The Lizhou thread cutting blades are made from high-quality cemented carbide materials, combined with advanced coatings and precise tooth profile grinding, enabling them to meet the machining requirements of various thread standards. Whether working with steel, stainless steel, or high-temperature alloys, these blades maintain excellent wear resistance and cutting stability, making them ideal for mass production and thread machining applications that demand high consistency.

2025-12-12

Lizhou Solid Carbide End Mill Series | GX GG BS TS AL Milling Solutions

The Lizhou end-mill series covers a wide range of materials, including steel, stainless steel, quenched and tempered steel, aluminum alloys, and titanium alloys, and corresponds to five major carbide end-mill lines: GX, GG, BS, TS, and AL. Available in flat-end, round-nose, ball-nose, and multi-flute configurations, these end mills are suitable for roughing, finishing, and high-speed machining. Featuring an ultra-fine-grain matrix and comprehensive quality control throughout the entire manufacturing process, these tools deliver more stable tool life and smoother machining performance.