Blog

FAQ

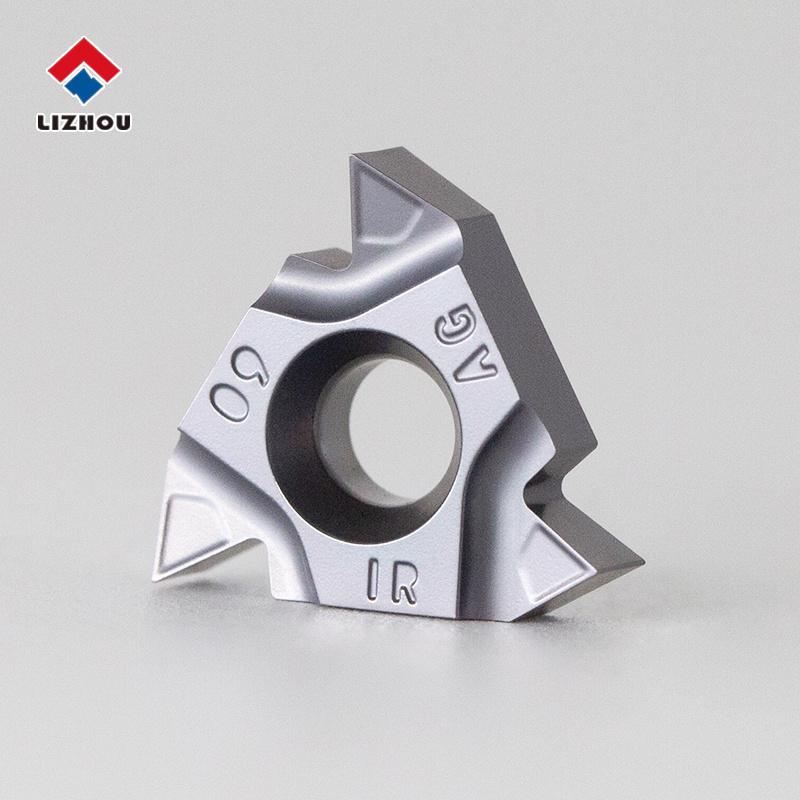

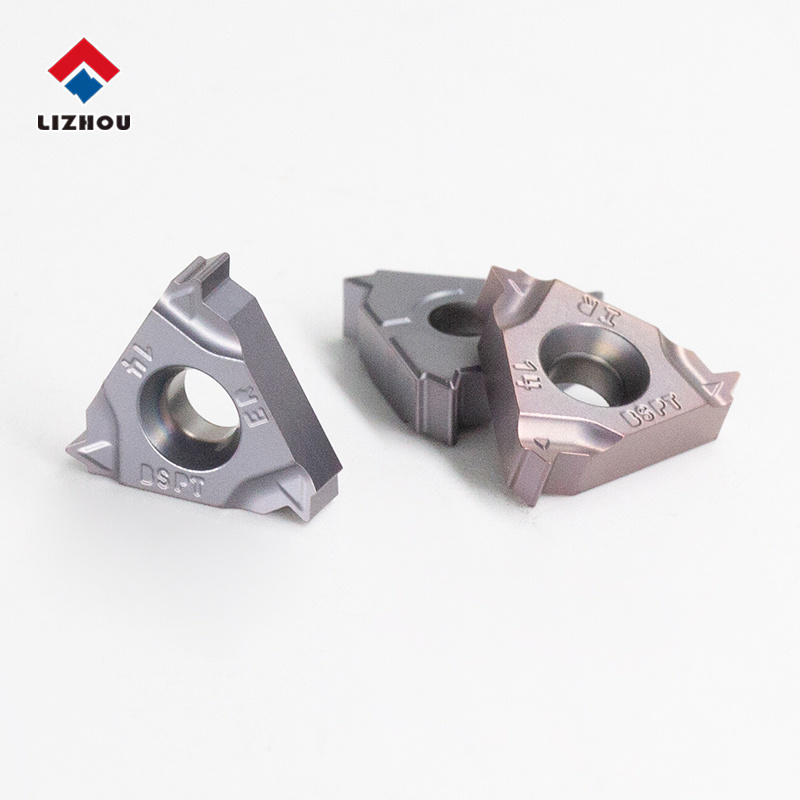

Lizhou Threaded Blade Series | High-Precision, Stable Thread-Machining Solution

Lizhou Threaded blade Series—The Reliable Choice for High-Precision Thread Machining

In today’s highly competitive manufacturing industry, the quality and efficiency of thread machining often directly affect part performance as well as the cycle time of the entire production line. Whether it’s small-batch mold components or large-scale mechanical structural parts, the stability, wear resistance, service life, and machining consistency of threading inserts are the key metrics that machining companies pay the most attention to.

For over thirty years, Lizhou Cemented Carbide has been deeply rooted in the industry, independently mastering the entire process—from raw material selection and powder metallurgy and coating technologies to blade forming—providing customers with more reliable and efficient threading tool solutions.

1. A comprehensively covered thread-machining system that adapts to a wider range of production needs.

There are many types of threads, and different industries have completely different requirements for precision, thread form, tooth depth, and surface finish.

Lizhou thread blades cover mainstream market standards, including:

British Standard Conical Pipe Thread BSPT )

American Standard Taper Pipe Thread ( NPT )

Whitworth thread ( Whitworth )

Metric thread ( ISO Metric )

General-purpose thread ( UN/UNF/UNC )

Whether customers need external thread blades, internal thread blades, precision blades, or coarse-thread blades, they can find the corresponding blade types and grooves at Lizhou.

2. A high-quality tungsten steel matrix delivers longer tool life and greater stability.

The cutting amount in thread machining is not large, but the blade’s resistance to chipping and wear must be extremely high.

Lizhou insists on using high-density, high-uniformity, premium tungsten steel powder as its raw material, which offers the following advantages:

Higher red hardness

Strong resistance to chipping, suitable for continuous machining.

High toughness, less likely to cause chipping at the blade tip.

Longer service life and more stable blade patterns.

No matter whether the customer is machining steel parts, cast iron, stainless steel, high-hardness steel, copper and aluminum materials, titanium alloys, or high-temperature alloys, they can select the corresponding grade and flute geometry to achieve optimal cutting performance.

III. Advanced Coating Technology—Reducing Cutting Friction and Extending Blade Life

The lifespan of threaded blades largely depends on the coating.

Lizhou uses a specialized coating with high wear resistance and a low coefficient of friction, giving the blades:

Reduce the cutting temperature at the tool tip

Reduce cutting adhesion and improve thread surface finish.

Enhance antioxidant capacity

Improve the consistency of thread profile.

Significantly extend blade life and reduce per-piece processing costs.

Particularly suitable for machining stainless steel, titanium alloys, and... Inconel Difficult-to-machine materials.

4. High thread accuracy and stable, standardized thread profiles reduce rework.

Lizhou thread blades undergo high-precision grinding and stringent quality control to ensure that the blade tooth profile meets industry standards.

For customers, this means:

The thread profile is more robust.

Better compliance, more stable go/no-go gauge testing.

Not easy to lose teeth or get strains.

High consistency in batch processing

For industries that pursue precision thread machining, pressure pipe threads, sealing threads, and mechanical structural threads, Lizhou blades can significantly improve the yield of good-quality products.

5. A wide variety of groove types to suit different machining scenarios.

Depending on the thread depth, material type, and toolpath method, Lizhou offers a variety of cutter groove designs, such as:

Sharp groove type (suitable for steel and cast iron)

Strengthened groove type (suitable for stainless steel and high-temperature alloys)

Low-resistance groove type (suitable for titanium and tough materials)

Wear-resistant groove type (suitable for large-scale processing)

Each knife groove has undergone extensive practical machining verification, allowing customers to confidently put it into production.

6. From cost to efficiency, delivering genuine processing value to our customers.

Choosing Lizhou thread blades means:

Longer blade life

The per-piece cost of the blade is lower.

Better thread stability, reducing rework.

Higher processing efficiency

Reducing the number of tool changes improves machine utilization.

For manufacturing enterprises that prioritize cost, efficiency, and delivery schedules, this represents a highly significant integrated advantage.

7. Lizhou—providing not just blades, but also comprehensive thread-machining solutions.

As a company with 30+ With years of experience in the R&D and manufacturing of cemented carbides, Lizhou not only offers standard threaded blades but also provides customers with:

Selection Recommendations for Different Thread Standards

Blade Grade Solutions for Special Materials

Customized groove type

OEM / ODM Customized services

Truly achieve: making thread machining simpler, more stable, and more efficient.

Recommended products