Product

FAQ

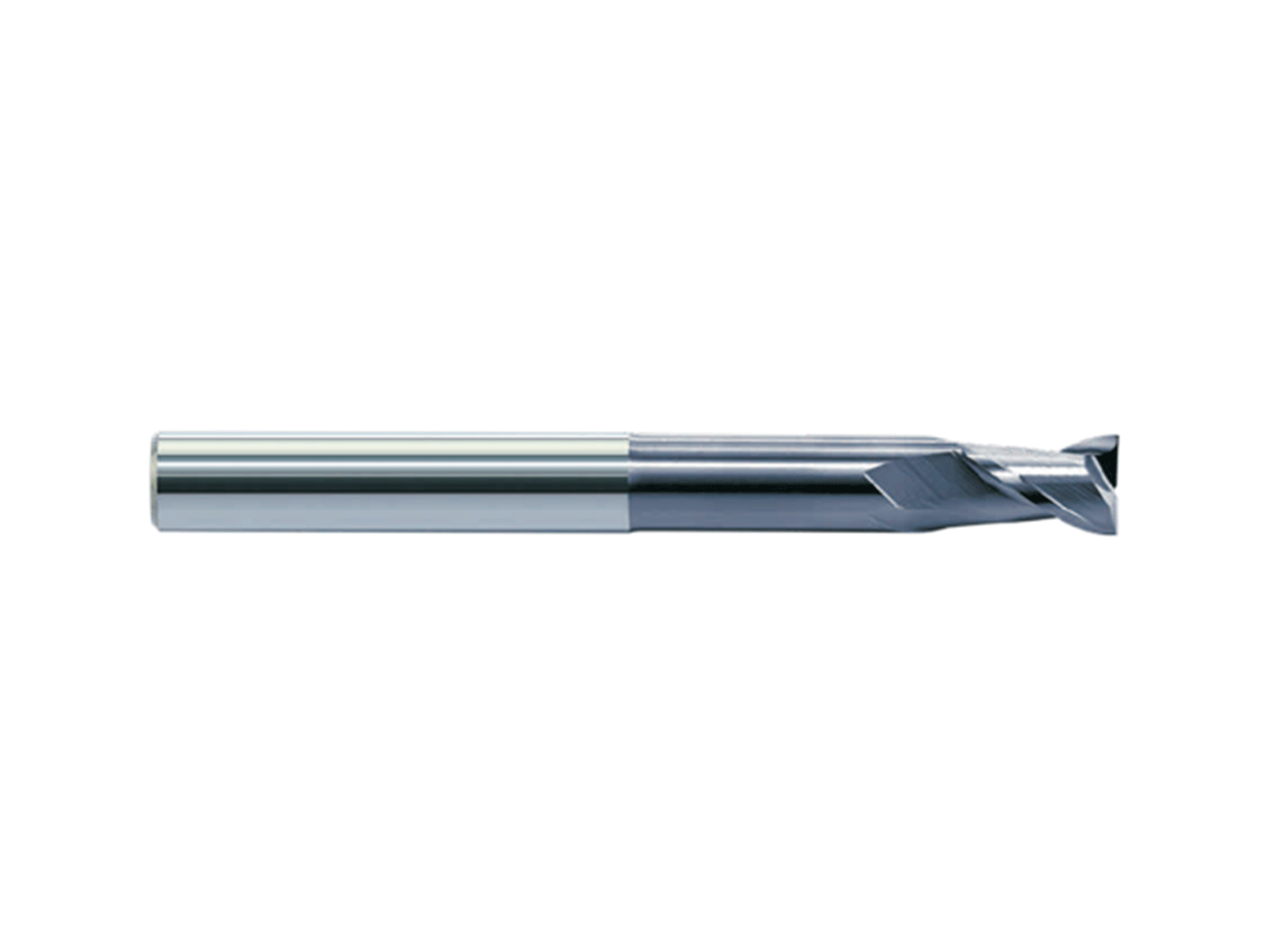

Chamfered LBC15S grade cemented carbide rod - metric (h5\h6)

China Lizhou Hard Alloy Source Factory

Grade:LBC15S

Classification :

Carbide Rod

keyword:

lizhou

LBC15s Tungsten Carbide Rods – High-Performance Carbide Solutions by Lizhou Carbide

Introduction to LBC15s Carbide Rods

As a leading carbide manufacturer with more than 30 years of expertise, Lizhou Carbide specializes in producing premium tungsten carbide rods for a wide range of cutting and wear-resistance applications. Among our advanced product grades, LBC15s carbide rods stand out for their balanced cobalt content, exceptional strength, and fine-grained microstructure. These rods are designed to meet the increasing demands of high-speed machining, precision cutting tools, and tough industrial environments.

2、Product Properties

Grade: LBC15S

Cobalt Content: 12%

Tungsten Carbide Content: 88%

Grain Size: 0.5μm

Density: 14.15g/cm3

Vickers Hardness: 1600Kg/mm2

Rockwell Hardness: 92.3

Bending Strength: 4300N/mm2

3、Meaning of Parameters & Their Technical Significance

Understanding the parameters of LBC15s carbide rods helps engineers and buyers select the right grade for specific machining needs:

Cobalt Content: Higher cobalt means greater toughness but lower wear resistance. At 10%, LBC15s offers balanced properties suitable for both roughing and finishing.

Flexural Strength: Indicates the maximum stress the rod can withstand before breaking; essential for tools subject to bending loads.

Hardness: Determines wear resistance. With 91.5 HRA, LBC15s can maintain sharp edges even during prolonged machining.

Density: Reflects material integrity; higher density means fewer internal defects.

Grain Size: Smaller grain sizes improve hardness and wear resistance while maintaining toughness. The 0.7 μm grains ensure a superior balance for demanding tool applications.

4. Applications of LBC15s Carbide Rods

LBC15s rods are engineered to perform in high-demand machining industries. Key applications include:

Cutting Tools

Solid carbide end mills

Twist drills and micro drills

Reamers, taps, and burrs

Router bits for wood and composite materials

Wear-Resistant Components

Punches and dies

Valve seats and nozzles

Precision measuring tools

Industries Served

Automotive: Engine parts, transmission components, and molds

Aerospace: High-temperature alloys, titanium machining

Mold-making: Injection molds, die-casting molds

General Engineering: Machining of stainless steel, carbon steel, cast iron, and non-ferrous alloys

Plastic & Composite Machining

Thanks to its fine grain structure, LBC15s performs well in machining composite and plastic materials where precision and surface finish are critical.

5. Features & Advantages

Compared to conventional carbide grades, LBC15s offers unique advantages:

Excellent balance of toughness and hardness – suitable for both interrupted and continuous cutting.

Fine-grain structure (0.7 μm) ensures sharp cutting edges and improved surface finish.

Extended tool life due to high wear resistance.

Resistance to thermal cracking, making it ideal for high-speed machining and dry cutting conditions.

High flexural strength (4200 MPa) enables stability in aggressive cutting operations.

Versatile grade – can handle a wide range of workpiece materials from hardened steels to non-ferrous alloys.

6. Precautions & Best Practices

To maximize the performance and service life of LBC15s carbide rods, users should follow best practices:

Proper Grinding Techniques

Use diamond wheels for grinding to maintain sharpness.

Ensure adequate coolant flow to prevent overheating.

Correct Coating Selection

Applying PVD or CVD coatings further enhances wear resistance and tool life depending on application.

Machining Parameters

Optimize feed rate and cutting speed according to the hardness of the workpiece.

Avoid excessive vibration or interrupted cuts that may cause edge chipping.

Storage and Handling

Store rods in a dry environment to prevent oxidation of cobalt binder.

Handle carefully to avoid micro-cracks before grinding or coating.

7. Technological Innovations at Lizhou Carbide

Lizhou Carbide has developed proprietary sintering and material refinement techniques that set LBC15s rods apart:

Ultra-fine grain technology: Achieved through advanced powder preparation, ensuring uniform microstructure.

Vacuum sintering processes: Improves density and reduces porosity for consistent mechanical strength.

Customized compositions: Ability to adjust cobalt content, grain size, and binder types for client-specific applications.

Coating compatibility: LBC15s rods are optimized for various coatings like TiAlN, AlCrN, and DLC, enhancing performance across industries.

Our 33 years of manufacturing expertise allow us to continuously refine carbide grades, providing global customers with reliable, high-performance solutions.

Conclusion

The LBC15s tungsten carbide rods by Lizhou Carbide deliver a powerful combination of 10% cobalt toughness, 4200 MPa flexural strength, 91.5 HRA hardness, and 0.7 μm fine grains. These properties make them a reliable choice for manufacturers seeking durability, precision, and efficiency in toolmaking and industrial applications.

By selecting Lizhou Carbide’s LBC15s rods, customers benefit not only from advanced material science but also from the commitment of a professional carbide factory with decades of experience and international reach.

Previous page

Next page

Use equipment

CNC machining centre

CNC machine tools

Carved machine

Factory Board

Factory Board

Factory Board

Factory Board

Factory Board

Recommended products

FAQ

2025-12-12

Lizhou Indexable U-Drill Series | High-Speed Drilling Solution for Large-Hole U-Drills

The Lizhou U-drill series is suitable for large-hole drilling in a variety of materials, including steel, stainless steel, alloy steel, and titanium alloys. It offers two structural types: square U-drills and peach-shaped U-drills. These drills combine rigidity, centering accuracy, and chip-removal efficiency, enabling multi-process machining that includes drilling, boring, and chamfering. Featuring high-quality carbide inserts and a stable tool body design, this series ensures more efficient batch drilling at lower costs.

2025-12-12

Lizhou Carbide Turning Inserts Series | Cemented Carbide CNC Turning Solutions

The Lizhou carbide turning blade series specializes in CNC turning applications using cemented carbide, covering common machining operations such as external cylindrical turning, end-face turning, roughing, and finishing. We offer diamond-shaped blades, square blades, triangular blades, peach-shaped blades, and peel-off blades, each tailored with specific grades and flute geometries for materials including cast iron, steel, stainless steel, high-hardness steel, and copper and aluminum. These blades help workshops enhance tool life and improve machining stability.

2025-12-12

Lizhou Threaded Blade Series | High-Precision, Stable Thread-Machining Solution

The Lizhou thread cutting blades are made from high-quality cemented carbide materials, combined with advanced coatings and precise tooth profile grinding, enabling them to meet the machining requirements of various thread standards. Whether working with steel, stainless steel, or high-temperature alloys, these blades maintain excellent wear resistance and cutting stability, making them ideal for mass production and thread machining applications that demand high consistency.

2025-12-12

Lizhou Solid Carbide End Mill Series | GX GG BS TS AL Milling Solutions

The Lizhou end-mill series covers a wide range of materials, including steel, stainless steel, quenched and tempered steel, aluminum alloys, and titanium alloys, and corresponds to five major carbide end-mill lines: GX, GG, BS, TS, and AL. Available in flat-end, round-nose, ball-nose, and multi-flute configurations, these end mills are suitable for roughing, finishing, and high-speed machining. Featuring an ultra-fine-grain matrix and comprehensive quality control throughout the entire manufacturing process, these tools deliver more stable tool life and smoother machining performance.