Product

FAQ

LX25 grade cemented carbide rod

China Lizhou Hard Alloy Source Factory

Grade:LX25

Classification :

Carbide Rod

keyword:

lizhou

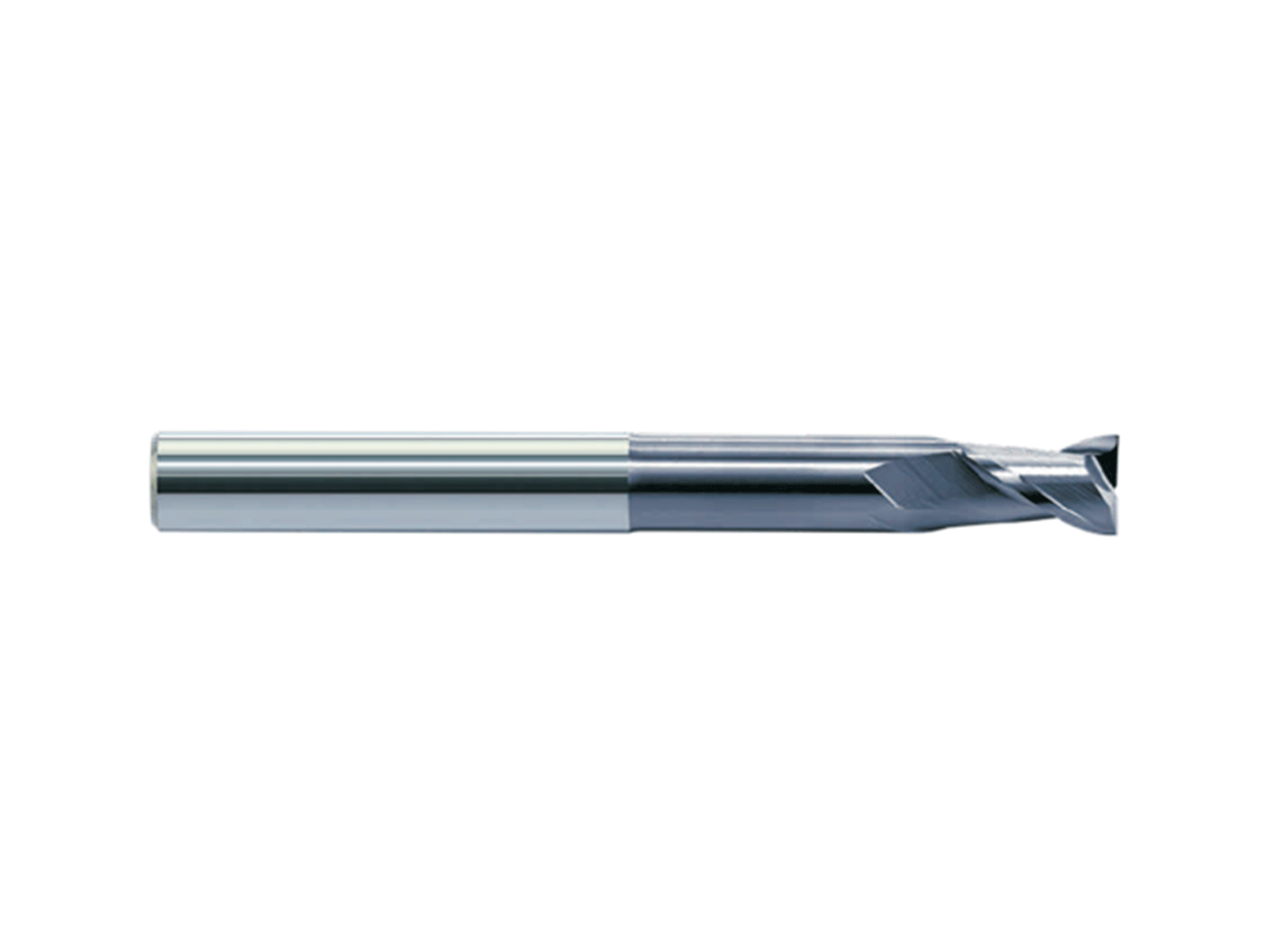

Lx25 Carbide Rods: High-Performance Tungsten Carbide Bars with 10% Cobalt Binder

Introduction

Tungsten carbide rods are the foundation of precision machining, toolmaking, and wear-resistant applications. Among the different carbide grades, Lx25 carbide rods have gained recognition for their exceptional balance between strength, toughness, and hardness. Manufactured by Lizhou Carbide, a specialized carbide rod factory, Lx25 rods are engineered to provide outstanding cutting performance and reliability in demanding industrial environments.

With 10% cobalt content, flexural strength of 3600 MPa, hardness of 91.5 HRA, density of 14.38 g/cm³, and a 0.8 μm fine grain size, the Lx25 carbide rod combines the toughness needed for heavy-duty machining with the wear resistance required for long service life. This makes it a versatile grade suitable for a wide variety of cutting tools, end mills, drills, reamers, and wear-resistant components.

In this article, we will analyze the advantages, numerical parameters, applications, performance features, precautions, and innovations behind the Lx25 carbide rod, providing a complete reference for engineers, toolmakers, and buyers searching for reliable carbide solutions.

1、Product Attributes

Grade: LBC15S, LX25

Cobalt Content: 10%

Tungsten Cobalt Content: 90%

Grain Size: 0.8μm

Density: 14.38g/cm3

Vickers Hardness: 1600Kg/mm2

Bending Strength: 3600N/mm2

2. Advantages and Performance Analysis

2.1 Optimized Toughness and Hardness Balance

The 91.5 HRA hardness ensures strong resistance to wear, while the 10% cobalt binder improves fracture toughness. This dual advantage makes Lx25 suitable for both finishing operations requiring precision and roughing tasks where shock resistance is critical.

2.2 High Flexural Strength

With a flexural strength of 3600 MPa, Lx25 rods can withstand significant mechanical stress without breaking. This performance is particularly important for high-speed cutting tools exposed to heavy cutting forces.

2.3 Fine Grain Structure for Precision Machining

The 0.8 μm ultrafine grain size provides excellent edge sharpness, allowing tools made from Lx25 rods to achieve high cutting precision and superior surface finish in workpieces.

2.4 Stable Material Density

The 14.38 g/cm³ density ensures a consistent microstructure that enhances both performance stability and wear resistance.

2.5 Long Tool Life

The synergy between cobalt content and grain size leads to superior resistance to thermal cracking and mechanical wear, extending the lifespan of tools and reducing tool change frequency.

3. Meaning of Numerical Parameters

Cobalt Content (10%) – The cobalt binder acts as the “glue” between tungsten carbide grains. At 10%, Lx25 achieves a balance between toughness and hardness, making it suitable for both general-purpose and semi-heavy machining.

Flexural Strength (3600 MPa) – Indicates the ability of the material to resist bending forces. A higher flexural strength means the rod can endure demanding cutting operations without fracture.

Hardness (91.5 HRA) – Reflects wear resistance. With this hardness, Lx25 is capable of cutting steel, stainless steel, and non-ferrous alloys while maintaining a sharp edge.

Density (14.38 g/cm³) – Shows material compactness. Higher density contributes to overall structural stability.

Grain Size (0.8 μm) – A finer grain size means a sharper cutting edge, higher precision, and smoother surface finishes.

4. Application Scenarios

4.1 Cutting Tools Manufacturing

End mills and slot cutters – Achieve precise surface finishes and long tool life.

Drills and reamers – Provide superior dimensional accuracy in high-speed drilling.

Thread mills and taps – Withstand cyclic stress in threading operations.

4.2 Wear-Resistant Components

Valve seats, bushings, and nozzles – Resist abrasion and erosion in harsh working environments.

Measuring instruments – Maintain precision under long-term wear conditions.

4.3 Automotive and Aerospace Industry

Machining hardened steels and alloy components used in engines and structural parts.

Reliable performance in heat-resistant alloys common in turbine blade production.

4.4 Mold and Die Industry

Punches, dies, and forming tools – Deliver durability in high-pressure forming processes.

Enhanced resistance to adhesive wear when forming non-ferrous metals.

5、Key Features of Lx25 Carbide Rods

Versatility: Suitable for a wide range of materials including carbon steel, stainless steel, cast iron, copper alloys, and aluminum alloys.

Thermal Stability: Maintains performance under high-speed cutting conditions.

Precision Edges: Fine grain size supports ultra-sharp cutting edges.

Reduced Tool Replacement: Longer lifespan leads to lower production costs.

Consistent Performance: Advanced manufacturing ensures stable quality across batches.

6. Precautions for Using Lx25 Carbide Rods

Proper Cutting Parameters: Select cutting speed, feed rate, and depth of cut according to workpiece material to maximize lifespan.

Adequate Cooling: For stainless steel and titanium alloys, ensure sufficient coolant supply to reduce built-up edges and thermal damage.

Avoid Excessive Shock Loads: Although Lx25 is tough, sudden impact or improper clamping may lead to chipping.

Regular Inspection: Monitor tool wear to prevent tool breakage that may damage workpieces.

Correct Grinding Technology: Use diamond grinding wheels and proper cooling during tool re-sharpening to avoid thermal cracks.

7. Technical Innovations and Manufacturing Excellence

At Lizhou Carbide, Lx25 rods are manufactured with advanced powder metallurgy techniques, including:

Uniform Grain Distribution: Ensures consistent hardness and toughness across the rod.

Vacuum Sintering Technology: Produces high density and eliminates pores, resulting in superior strength.

Precision Grinding: Provides excellent dimensional accuracy for tool manufacturers.

PVD Coating Compatibility: Lx25 rods can be coated with TiN, TiAlN, AlCrN, or other PVD coatings to further enhance wear resistance.

These innovations enable Lx25 carbide rods to meet the demanding requirements of high-speed cutting, dry machining, and precision manufacturing industries.

8. Competitive Advantages of Lx25 over Other Grades

Compared to LBC05 (6% Co): Lx25 offers greater toughness, making it better for interrupted cuts and harder materials.

Compared to LBC25s (12% Co): Lx25 balances toughness with slightly higher hardness, making it suitable for general-purpose applications.

Ideal for users seeking a middle-grade carbide rod that works across diverse applications.

Conclusion

The Lx25 carbide rod represents a high-quality, versatile solution for modern machining and wear-resistant applications. With 10% cobalt content, 3600 MPa flexural strength, 91.5 HRA hardness, 14.38 g/cm³ density, and 0.8 μm fine grain size, it delivers the perfect balance between toughness and wear resistance.

Backed by Lizhou Carbide’s advanced manufacturing technology, Lx25 rods are engineered for precision cutting tools, end mills, drills, reamers, and wear-resistant parts in industries such as automotive, aerospace, mold-making, and general engineering.

For engineers and buyers searching for high-performance carbide rods, Lx25 offers an ideal combination of durability, precision, and cost-effectiveness, making it a reliable choice for long-term productivity.

Use equipment

CNC machining centre

CNC machine tools

Carved machine

Factory Board

Factory Board

Factory Board

Factory Board

Factory Board

Recommended products

FAQ

2025-12-12

Lizhou Indexable U-Drill Series | High-Speed Drilling Solution for Large-Hole U-Drills

The Lizhou U-drill series is suitable for large-hole drilling in a variety of materials, including steel, stainless steel, alloy steel, and titanium alloys. It offers two structural types: square U-drills and peach-shaped U-drills. These drills combine rigidity, centering accuracy, and chip-removal efficiency, enabling multi-process machining that includes drilling, boring, and chamfering. Featuring high-quality carbide inserts and a stable tool body design, this series ensures more efficient batch drilling at lower costs.

2025-12-12

Lizhou Carbide Turning Inserts Series | Cemented Carbide CNC Turning Solutions

The Lizhou carbide turning blade series specializes in CNC turning applications using cemented carbide, covering common machining operations such as external cylindrical turning, end-face turning, roughing, and finishing. We offer diamond-shaped blades, square blades, triangular blades, peach-shaped blades, and peel-off blades, each tailored with specific grades and flute geometries for materials including cast iron, steel, stainless steel, high-hardness steel, and copper and aluminum. These blades help workshops enhance tool life and improve machining stability.

2025-12-12

Lizhou Threaded Blade Series | High-Precision, Stable Thread-Machining Solution

The Lizhou thread cutting blades are made from high-quality cemented carbide materials, combined with advanced coatings and precise tooth profile grinding, enabling them to meet the machining requirements of various thread standards. Whether working with steel, stainless steel, or high-temperature alloys, these blades maintain excellent wear resistance and cutting stability, making them ideal for mass production and thread machining applications that demand high consistency.

2025-12-12

Lizhou Solid Carbide End Mill Series | GX GG BS TS AL Milling Solutions

The Lizhou end-mill series covers a wide range of materials, including steel, stainless steel, quenched and tempered steel, aluminum alloys, and titanium alloys, and corresponds to five major carbide end-mill lines: GX, GG, BS, TS, and AL. Available in flat-end, round-nose, ball-nose, and multi-flute configurations, these end mills are suitable for roughing, finishing, and high-speed machining. Featuring an ultra-fine-grain matrix and comprehensive quality control throughout the entire manufacturing process, these tools deliver more stable tool life and smoother machining performance.