Blog

FAQ

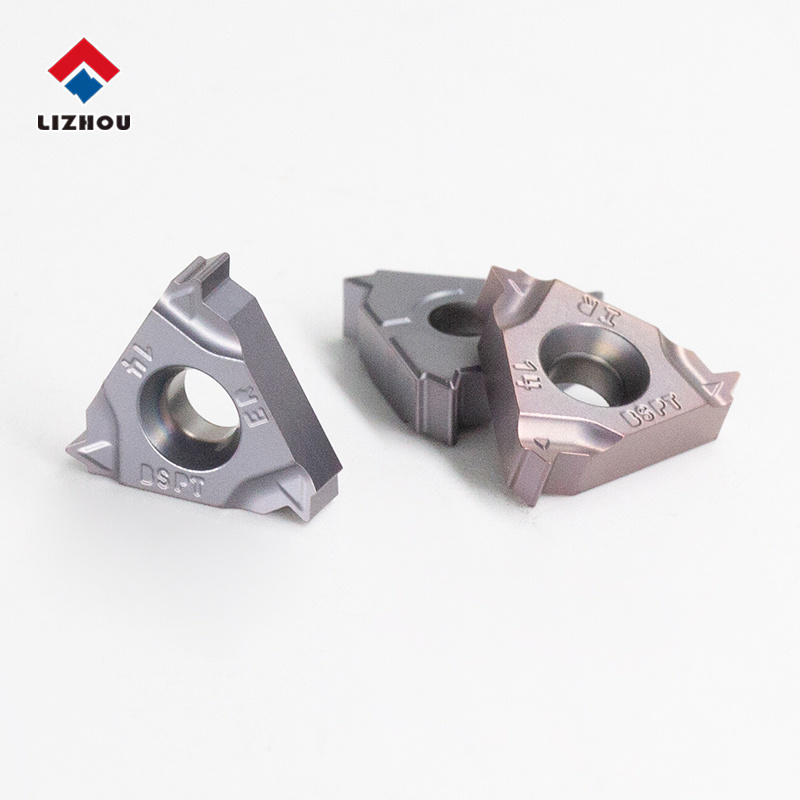

Lizhou Cemented Carbide | NPT American Standard Internal and External Thread Blades for Tapered Pipe Connections

US standard tapered pipe thread blade ( NPT ) — An indispensable machining tool for piping and sealing structures, the U.S.-standard tapered pipe thread is widely used in fields such as oil pipelines, hydraulic systems, fire-fighting equipment, and construction machinery. NPT ) remains one of the widely adopted standards.

Due to their inherent taper, these threads place higher demands on the tooth profile accuracy, edge stability, and cutting consistency of the blades during both machining and assembly.

The U.S.-standard tapered pipe thread blades launched by Lizhou are specifically designed for... NPT The design features a threaded structure suitable for both internal and external thread machining, ensuring thread accuracy while also optimizing machining efficiency and tool life.

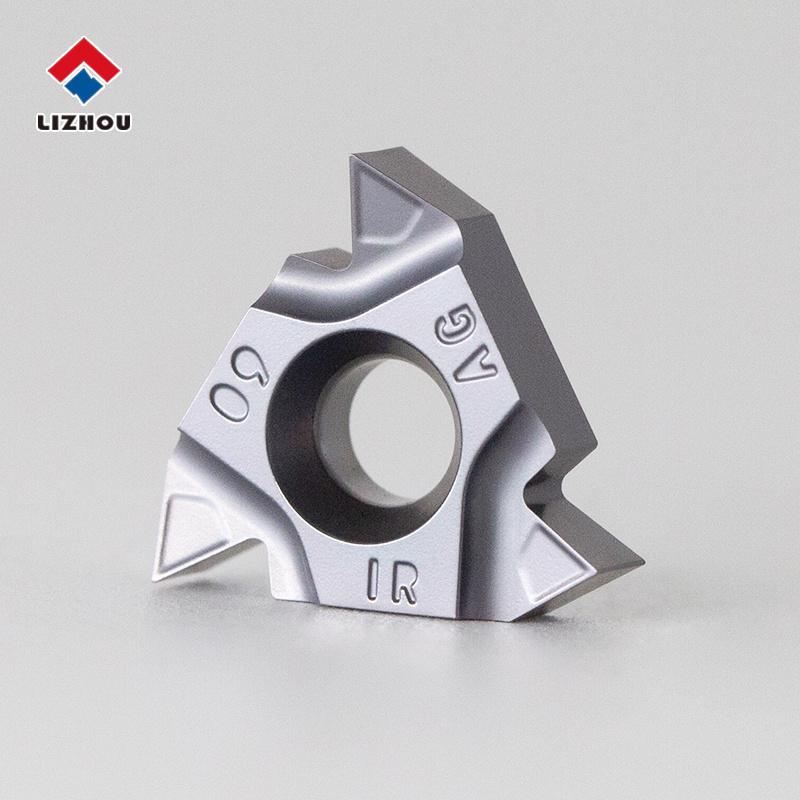

One, 1:16 Taper + 60 °Tooth profile, compliant with NPT Thread Structure Characteristics

The biggest difference between American standard tapered pipe threads and common straight threads is:

1:16 Tapered structure

60 ° Standard tooth profile angle

This tapered design allows the threads to gradually engage as they are tightened, thereby achieving a good sealing effect.

During the manufacturing process, if the taper or tooth profile is not accurately controlled, it can easily lead to sealing failures, assembly difficulties, and even rework.

Lizhou U.S.-standard threaded blades are manufactured with strict adherence to tooth profile grinding and angle control. NPT Standard implementation ensures stable thread formation and smooth assembly.

II. Actual Differences Between Metric and Whitworth Thread Blades

From a manufacturing perspective, the American standard tapered pipe thread differs significantly from metric or Whitworth threads:

Metric threads are primarily straight threads, emphasizing dimensional consistency.

Uses Whiting threads 55 ° Tooth profile, with greater emphasis on arc transitions and strength.

NPT Threaded both ways 60 ° The tooth profile, which also includes taper variations, places higher demands on blade stability.

Therefore, American-style tapered pipe thread blades are designed with greater emphasis on blade tip strength, cutting stability, and consistent performance over the long term.

3. Indexable structure design, suitable for batch pipe fitting processing.

This series features a indexable thread-cutting blade design, and its multi-cutting-edge configuration proves highly practical in actual production:

After a single cutting edge wears out, it can be repositioned and continued in use.

Reduce downtime caused by frequent blade changes.

Improve blade utilization.

Reduce the per-unit processing cost.

For the mass production of pipe fittings and joint components, this structural advantage is particularly evident.

4. Equipped with built-in chip-breaking grooves for a more stable cutting process.

NPT Thread machining typically involves long cutting paths, and if chip control is inadequate, problems such as chip entanglement and tool jamming can easily occur.

The LiZhou U.S.-standard thread blade incorporates a reasonably designed chip-breaker groove structure, enabling:

The chips break more easily.

The chip removal direction is clearer.

Reduce sudden loads during the cutting process.

Improve overall machining stability

Especially in the machining of stainless steel and tough materials, chip-breaking performance significantly affects blade life.

5. High-quality tungsten steel matrix, balancing sharpness and durability.

Lizhou consistently adheres to the use of high-quality tungsten steel raw materials and strictly controls the quality of the substrate during blade manufacturing, ensuring that the blades possess:

The cutting edge is sharp, and the cutting resistance is low.

Stable wear resistance

Strong resistance to chipping

The thread surface quality is more uniform.

Whether it's steel parts, stainless steel, or hardened steel parts and stainless steel materials, all can maintain excellent cutting performance.

6. Covers both internal and external threads; multiple models available for easy selection.

This series can simultaneously meet NPT The machining of internal and external threads commonly finds applications including:

Internal threading in pipes

External thread machining for pipe fittings

Hydraulic system fittings

Firefighting Equipment and Engineering Pipelines

By configuring different grades, it can better meet the machining requirements for steel parts, stainless steel, and hardened materials.

Lizhou Cemented Carbide has been deeply engaged in the cutting tool industry for 32 years, implementing stringent quality control throughout the entire process—from raw material selection to finished product shipment.

We’re more concerned with the blade’s long-term performance in actual machining, rather than just the parameters themselves.

For customers who need to machine American standard tapered pipe threads over the long term, stable and predictable machining results are paramount.

If you are processing NPT For American-style tapered pipe threads, and if you're looking to strike a balance among sealing performance, machining stability, and tool life, the Lizhou American-thread blade is a practical and reliable choice.

It is more suitable for real-world production environments and can be used reliably over the long term in pipeline and fitting fabrication.

Recommended products