Blog

FAQ

Lizhou Cemented Carbide | BSPT British Standard Taper Pipe Thread Internal and External Thread Blades

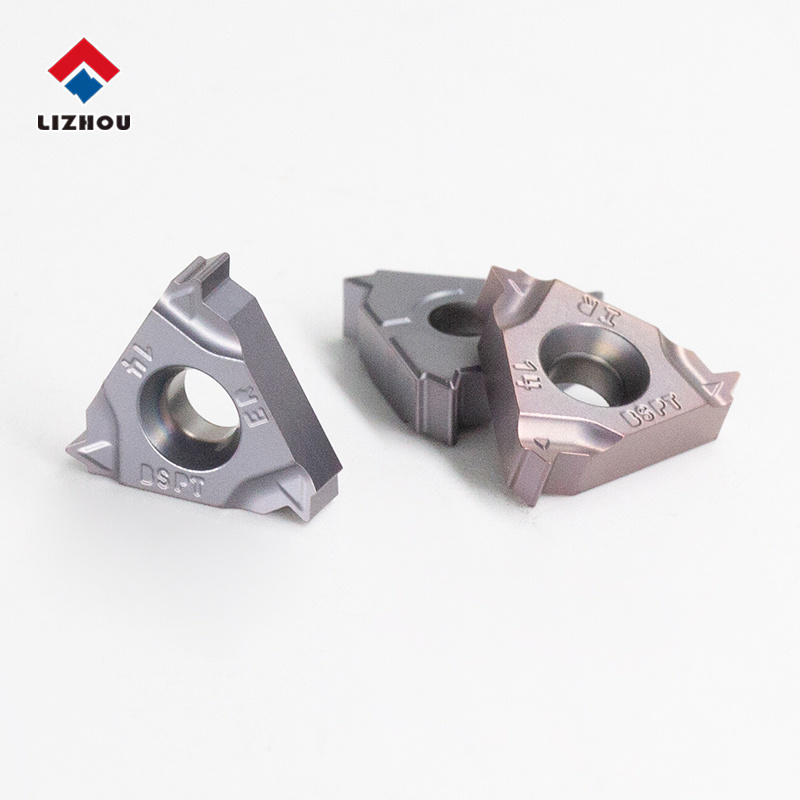

British Standard Taper Pipe Thread Blade ( BSPT )

Compared to conventional straight threads, these threads not only need to meet dimensional requirements but also must exhibit excellent sealing performance after assembly. Consequently, during the machining stage, higher demands are placed on the tooth profile accuracy of the threading inserts, cutting stability, and edge durability.

Lizhou’s imperial-cone pipe thread blades ( BSPT ), it is specifically designed for this type of application scenario and is suitable for both internal and external thread machining. While ensuring the quality of thread formation, it also takes into account machining efficiency and tool life.

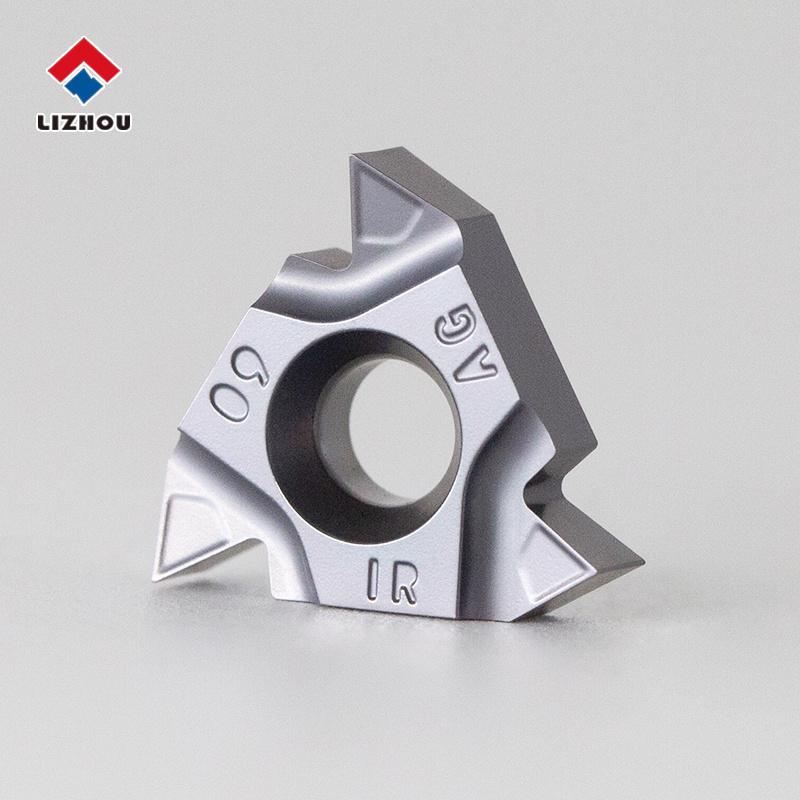

One, 55 °Tooth profile + 1:16 Taper, compliant with BSPT Thread Structure Characteristics

British Standard Conical Pipe Thread BSPT The structural characteristics of ) are mainly reflected in two aspects:

55 ° tooth profile angle

1:16 Tapered structure

With U.S. standards NPT Compared to threads, BSPT It also features a tapered design, but its sealing mechanism relies more on threaded engagement combined with sealing materials (such as PTFE tape or sealant) rather than solely on the interference fit between metals.

This requires that the thread profile be accurately machined and that the surface quality remain consistent; otherwise, during assembly, leakage or difficulty in tightening may easily occur.

Lizhou imperial-thread blades are manufactured strictly according to... BSPT Standard control of the thread profile angle and contour ensures that the machined threads are easier to assemble and more conducive to subsequent sealing operations.

II. Differences in Machining Between Metric and U.S.-Standard Thread Blades

In actual machining, imperial units BSPT The thread has distinct differences from other common threads:

Metric thread: straight thread, 60 ° Tooth profile, emphasizing dimensional consistency

Widewa thread: 55 ° Tooth profile: arc-shaped tooth top and tooth root, emphasizing strength.

US system NPT :60 ° Tooth profile + Taper, emphasizing metal sealing

Imperial system BSPT :55 ° Tooth profile + Taper, which places greater emphasis on assembly stability and sealing fit.

Therefore, BSPT When machining threads, higher demands are placed on the blade’s cutting edge stability and form consistency; therefore, other thread-cutting blades cannot simply be used as substitutes.

3. Indexable structure, suitable for batch processing of pipe fittings.

The Lizhou imperial-thread blade features a indexable insert design, and its multi-cutting-edge configuration offers greater advantages in actual production:

After a single cutting edge wears out, it can be repositioned for continued use.

Reduce downtime caused by frequent blade changes.

Improve blade utilization.

Reduce the per-unit processing cost.

For customers who need to process pipe fittings, valve bodies, or pipeline components over the long term, this design is even more hassle-free.

4. Equipped with built-in chip flutes for more reliable blind hole machining.

In internal thread machining, especially in blind-hole threading, chip removal is particularly critical.

This series of imperial-threaded blades features a rationally designed chip groove that, during cutting, can:

Effectively guide chip evacuation

Reduce thread buildup and chip clogging.

Reduce the instantaneous load on the cutting edge.

Improve the continuity of the processing procedure.

Even on tough materials such as stainless steel, it can maintain a relatively smooth cutting condition.

5. Made of high-quality tungsten steel, it’s sharp, wear-resistant, and more stable.

Lizhou has always adhered to using high-quality tungsten steel as the blade substrate and strictly controls the quality of both the material and the cutting edge during the manufacturing process, ensuring that its imperial-thread blades possess:

The blade is sharp and offers low cutting resistance.

Wear resistance is stable and not easily prone to rapid dulling.

Strong resistance to chipping

The thread surface quality is more uniform.

Suitable for machining steel parts, stainless steel, as well as certain hardened steel and hardened stainless steel components.

6. Covers both internal and external threads, suitable for a variety of application scenarios.

Lizhou British-style tapered pipe thread blades can be used for:

BSPT Internal thread machining

BSPT External thread machining

Common applications include:

Hydraulic system pipelines

Air compressor pipeline connection

European standard device interface

Industrial Pipe Fittings and Joints

For processing enterprises that need to handle multiple pipeline structures simultaneously, this is highly adaptable.

Lizhou Cemented Carbide has been deeply engaged in the cutting tool industry for 32 years, rigorously controlling every stage—from raw material selection and manufacturing processes to finished-product inspection.

We place greater emphasis on the long-term performance of cutting tools in real machining environments rather than on short-term parameters.

Stability, durability, and ease of use have always been the design principles consistently upheld by Lizhou’s imperial-thread blades.

If you are machining imperial tapered pipe threads... BSPT ), and if you're looking to strike a balance between assembly reliability, machining stability, and tool life, LiZhou imperial-thread blades will be a practical and reliable choice.

It is suitable for real production environments and can demonstrate its value over long-term use.

Recommended products