Blog

FAQ

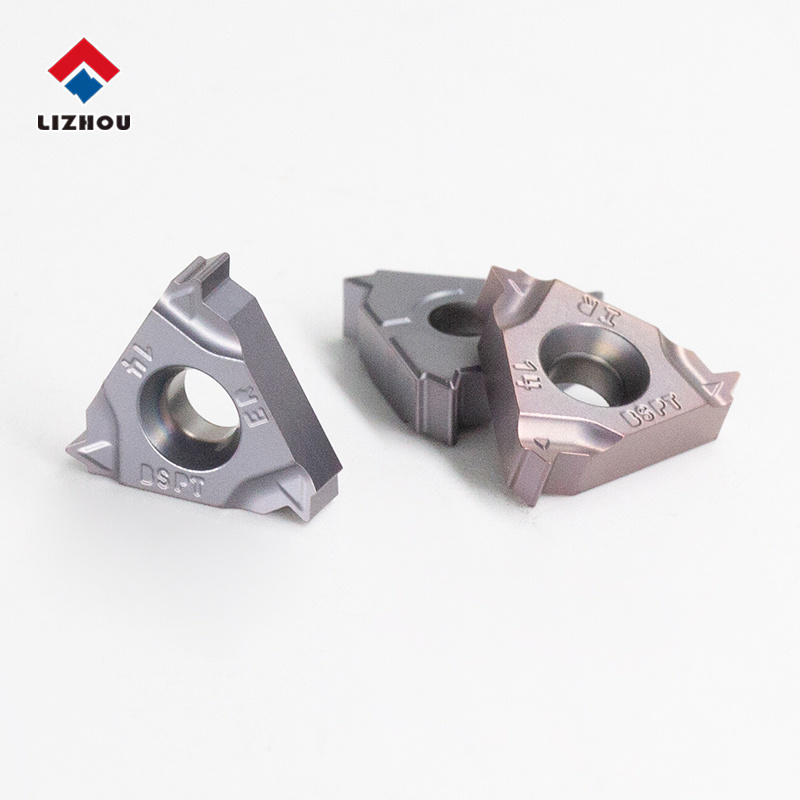

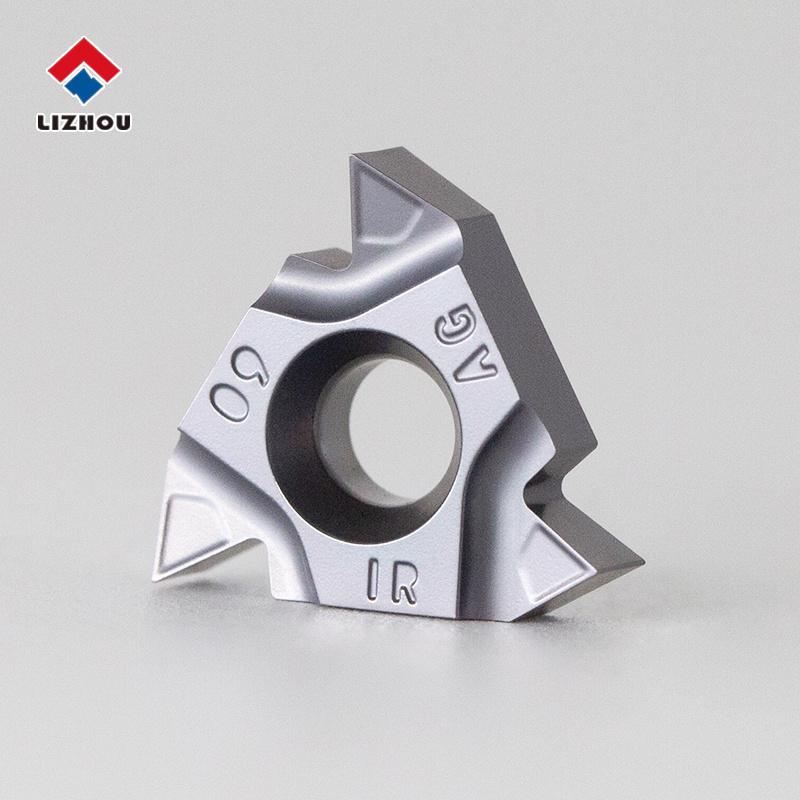

Wyeth 55° Internal Thread Blade | Lizhou Cemented Carbide

Wu's threaded blade — A stable machining option better suited for imperial thread structures

In thread machining, in addition to the common metric and U.S. standard threads, there are also Whitworth threads ( Whitworth Thread ) It is still widely used in some imperial equipment, piping systems, and traditional mechanical structures.

The structural characteristics of this type of thread dictate that, during machining, higher requirements are placed on the blade’s tooth profile accuracy, cutting edge strength, and stability.

The Huishi threaded blades launched by Lizhou are specifically designed for this purpose. 55 ° Designed with tooth profiles, arc-shaped tooth tops, and tooth root structures, it is suitable for machining applications that demand high thread strength and stable fit.

One, 55 °Tooth profile + The arc-shaped tooth top and tooth root better match the Wihl thread structure.

With the metric system ISO Common threads 60 ° With different tooth profiles, the most distinctive feature of the Whitworth thread is that its thread angle is: 55 °

Both the tooth top and tooth root feature rounded transitions.

This design can effectively reduce stress concentration and enhance the strength and durability of threaded connections; therefore, it was widely adopted in early imperial standards as well as in certain piping and equipment structures.

During the machining process, inaccurate tooth profile angles or arc transitions can easily lead to poor thread engagement.

Lizhou Whitworth thread blades are precisely ground according to Whitworth standards, ensuring stable thread formation and smooth assembly.

II. Compared to metric thread blades, greater emphasis is placed on edge strength and smooth cutting performance.

From the perspective of actual machining experience, Whithworth threads place greater emphasis on “smoothness” and “durability” during cutting.

Compared to metric thread blades, Whitworth thread blades place greater emphasis in their design on:

Is the force evenly distributed on the blade tip?

Is the blade edge prone to chipping?

Is the arc tooth profile fully formed?

Lizhou has made targeted optimizations to the blade’s cutting-edge structure, enabling smoother cutting when machining steel and stainless steel, as well as enhancing the durability of the cutting edge. This makes it particularly well-suited for continuous machining operations or workpieces with high requirements for thread strength.

3. Indexable structure design to reduce long-term usage costs.

Hui's thread machining often involves batch production. If the entire cutting tool is frequently replaced, not only will costs be high, but the machining rhythm will also be affected.

This series features a indexable thread-cutting blade design:

Multi-cutting-edge design

After a single cutting edge wears out, it can be repositioned for continued use.

High blade utilization.

Reduce the number of tool changes.

For customers who need to process Whitworth threads over the long term, this structure is more hassle-free in actual production.

4. Equipped with built-in chip-breaking grooves to improve chip-control performance.

During thread machining, if chips cannot be broken off smoothly, problems such as chip entanglement, surface roughening, and even chipping of the cutting edge are likely to occur.

The Lizhou Wyeth threaded blade comes with an integrated chip-breaking groove design, which allows it to:

Effectively control chip length

Reduce the risk of thread entanglement

Reduce the cutting edge load

Make the cutting process more stable.

This is particularly important when machining stainless steel or steels with higher toughness.

5. High-quality tungsten steel matrix, balancing sharpness and wear resistance.

The blade substrate material directly determines the service life.

Lizhou insists on using high-quality tungsten steel materials and combining them with mature manufacturing processes, ensuring that Whish thread blades possess:

The blade is sharp and offers low cutting resistance.

Wear resistance is stable and not easily prone to rapid dulling.

Strong resistance to chipping

The thread surface has better smoothness.

In both steel and stainless steel internal thread machining, good machining consistency can be maintained.

6. Primarily used for internal thread machining, suitable for a variety of application scenarios.

This series of WYSE threaded blades is primarily used for internal thread machining and is suitable for a variety of common working conditions, such as:

Internal threads for imperial structural components

Internal thread for pipe connection

Threaded fittings for equipment components

Traditional standard part repair and machining

For industries that need to balance thread strength and assembly reliability, Whitworth threads still hold irreplaceable value.

Seven, thirty-two years of persistence—just to ensure the blades last.

For the past 32 years, Lizhou Cemented Carbide has been exclusively focused on the R&D and manufacturing of cutting tools, rigorously controlling every stage—from raw material selection to finished-product inspection.

We place greater emphasis on the blade’s performance in actual machining rather than on short-term parameters.

For customers, a Wyeth threading blade that offers stable performance, consistent batch-to-batch quality, and predictable machining results is truly the kind of product worth long-term collaboration.

If you’re machining Whitworth threads and are looking for a blade that strikes a better balance between strength, stability, and tool life, the Lizhou Whitworth thread blade is a practical and reliable choice.

It doesn’t pursue complex designs; instead, it focuses on doing a great job with thread machining—ensuring durability and stability over the long term.

Recommended products