Product

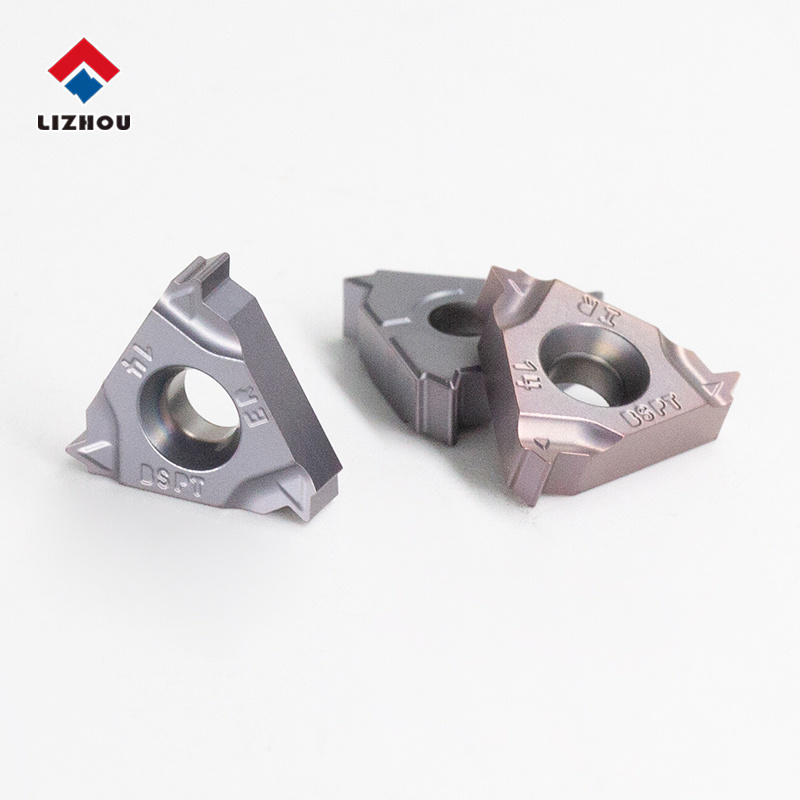

NPT US thread insert

China Lizhou Hard Alloy Source Factory

Product Name:NPT Therading inserts

Coating : PVD

Brand number:LMP203

Classification :

Threading insert

keyword:

lizhou

Product Details: 16IR11.5NPT Carbide Threading Insert

Introduction

In the field of precision machining, threading is one of the most critical operations, as it directly determines the functionality, sealing, and reliability of mechanical components. Among the many standards in thread manufacturing, the NPT (National Pipe Thread) standard is widely used in North America and global industries for its ability to create pressure-tight seals in fluid and gas piping systems.

To meet the increasing demand for high-efficiency and precise thread machining, LIZHOU Carbide, a professional carbide manufacturer, has developed the 16IR11.5NPT carbide threading insert. This insert is designed for internal threading according to American Standard Pipe Thread specifications, delivering unmatched cutting accuracy, durability, and versatility across a wide range of materials including steel, stainless steel, cast iron, aluminum, copper, and titanium alloys.

This article provides an in-depth analysis of the advantages, technical meanings of insert coding, numerical parameters, applications, functions, features, usage precautions, and innovative technologies behind the 16IR11.5NPT insert.

Type | External Thread | Basic Dimensions (mm) | PVD | |||||

Pitch | I.C | S | D | a ° | LPP203 | LMP203 | ||

16ER11.5NPT | 11.5 | 9.525 | 3.52 | 4.0 | 55 ° |

| √ | |

16ER14NPT | 14 | 9.525 | 3.52 | 4.0 | 60 ° |

| √ | |

Type | Internal Thread | Basic Dimensions (mm) | PVD | |||||

Pitch | I.C | S | D | a ° | LPP203 | LMP203 | ||

16IR11.5NPT | 11.5 | 9.525 | 3.52 | 4.0 | 55 ° |

| √ | |

16IR14NPT | 14 | 9.525 | 3.52 | 4.0 | 60 ° |

| √ | |

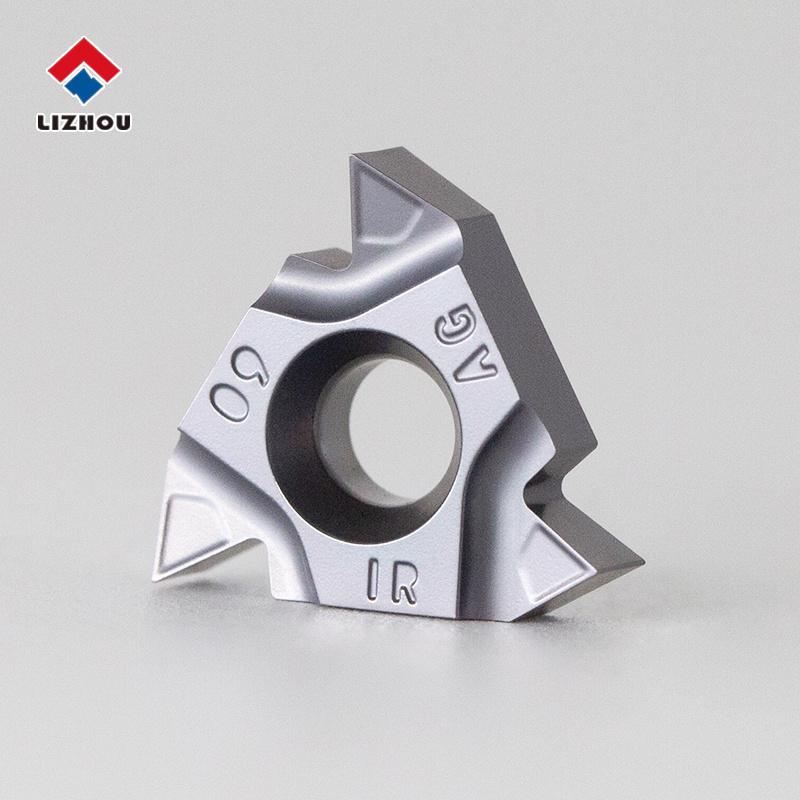

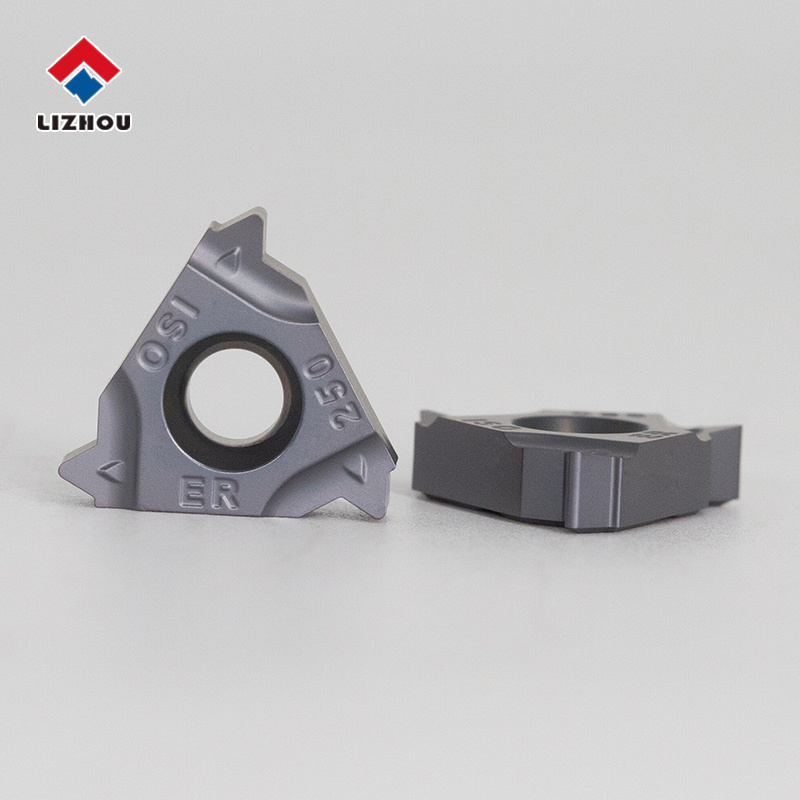

1. Product Code Breakdown: Understanding “16IR11.5NPT”

Each letter and number in the insert code has a specific meaning that defines its geometry and application. Understanding the code is essential for proper tool selection.

16: Insert size indicator. Refers to the inscribed circle (I.C) dimension of the insert, which is 9.525 mm. This ensures compatibility with standardized toolholders.

I: Designates internal threading. This insert is specifically engineered for producing threads inside a bore.

R: Refers to the thread direction. “R” means right-hand thread, which is the most common threading direction.

11.5NPT: Indicates the pitch and standard. Here, 11.5 threads per inch (TPI) conform to NPT (National Pipe Thread) specifications, with a taper angle of 1°47′ per side and a thread angle of 60°.

Together, “16IR11.5NPT” precisely defines the tool: a 16-size carbide insert designed for internal, right-hand, 11.5 TPI NPT threading.

2. Numerical Parameters

The basic dimensions and technical data of the 16IR11.5NPT insert include:

Insert Type: Internal threading insert

Pitch: 11.5 TPI

Inscribed Circle (I.C.): 9.525 mm

Thickness (S): 3.52 mm

Hole Diameter (D): 4.0 mm

Thread Angle (α): 60°

Coating: PVD (Physical Vapor Deposition) available for enhanced wear resistance

These precise geometrical dimensions allow consistent engagement with the workpiece, ensuring both accuracy and repeatability in production environments.

3. Advantages of Carbide Threading Inserts

Carbide threading inserts such as the 16IR11.5NPT offer significant advantages compared to high-speed steel (HSS) tools or conventional threading methods:

High Wear Resistance – Submicron carbide substrate ensures long tool life under demanding cutting conditions.

Superior Heat Resistance – Capable of withstanding high cutting temperatures, particularly in continuous production.

Dimensional Accuracy – Maintains strict adherence to NPT thread specifications, ensuring leak-tight sealing.

Surface Finish Quality – Produces smooth and burr-free thread surfaces that reduce friction in pipe connections.

Efficiency in Production – Enables higher cutting speeds and feeds, reducing cycle times and increasing productivity.

Versatility – Can process a wide range of materials, from soft metals like aluminum to difficult-to-machine stainless steels and titanium alloys.

4. Application Scenarios

The 16IR11.5NPT threading insert finds broad application in industries requiring reliable and precise pipe threads:

Oil & Gas: Threading of pipe joints, valves, and couplings requiring pressure-sealed connections.

Plumbing & HVAC: Manufacturing threaded fittings for water supply, heating, and cooling systems.

Aerospace: Precision threading of lightweight alloys used in hydraulic and fuel systems.

Automotive: Engine and exhaust system components with fluid/gas passage threads.

General Engineering: Any equipment requiring NPT threads for safe and reliable assembly.

5. Function and Role of 16IR11.5NPT

Thread Formation – Designed to cut precise NPT threads internally with the correct pitch and angle.

Seal Integrity – Ensures threads conform to taper requirements, providing leak-proof joints without additional sealing compounds.

Interchangeability – Guarantees that the produced threads fit seamlessly with standard NPT fittings available worldwide.

Durability in Operation – Retains cutting edge sharpness and stability for consistent results across long production runs.

6. Key Features

Carbide Substrate – Engineered from ultra-fine carbide grains for optimal hardness and toughness balance.

PVD Coating Technology – Thin, hard coating improves resistance to wear, adhesion, and oxidation.

Optimized Cutting Geometry – Provides controlled chip evacuation, reducing cutting forces and vibration.

Universal Toolholder Compatibility – Standardized insert size ensures easy replacement and flexible use.

Precision Manufacturing – Ground cutting edges guarantee high repeatability and dimensional accuracy.

7. Precautions for Use

To maximize performance and tool life, the following should be observed:

Correct Toolholder Selection – Ensure the insert matches the designated toolholder and clamping system.

Appropriate Cutting Parameters – Adjust speed, feed, and depth of cut based on material being machined.

Use of Coolant – Apply high-pressure coolant for stainless steel, titanium, or other heat-resistant alloys to improve chip evacuation and tool life.

Avoid Interrupted Cuts – Consistent cutting contact prolongs insert life and prevents chipping.

Inspection & Replacement – Regularly check for flank wear or edge chipping; replace inserts promptly to maintain thread quality.

8. Technical Innovations and Patented Developments

LIZHOU Carbide integrates cutting-edge research into the design of its threading inserts, including:

Nano-structured PVD Coatings – Enhanced adhesion strength, reducing coating delamination in high-load applications.

Chipbreaker Engineering – Customized chip control for threading operations to prevent chip entanglement in deep holes.

Precision Edge Honing – Micro-honed cutting edges reduce micro-chipping and extend tool stability.

Toughened Carbide Grades – Improved resistance against thermal cracking during high-speed machining.

These technological advancements ensure that 16IR11.5NPT inserts deliver performance superior to conventional threading tools, helping manufacturers reduce downtime and achieve higher-quality production.

9. Why Choose LIZHOU Carbide 16IR11.5NPT Inserts?

Manufacturer Expertise – With years of experience in carbide production, LIZHOU guarantees stable quality and competitive pricing.

Customizable Solutions – Inserts can be supplied with different coatings, grades, or geometries tailored to specific applications.

Global Standard Compliance – Conforms strictly to ANSI/ASME NPT standards, ensuring international compatibility.

Large-Scale Production Capacity – Ensures consistent supply for distributors and industrial users.

Conclusion

The 16IR11.5NPT carbide threading insert from LIZHOU Carbide represents the perfect balance of precision, durability, and efficiency in threading operations. With its optimized carbide substrate, advanced coating technology, and compliance with American NPT standards, it ensures leak-proof, high-accuracy threads for a wide variety of industries ranging from oil & gas to automotive and aerospace.

By combining cutting-edge technology with strict quality control, LIZHOU offers customers a reliable threading solution that reduces production costs while maximizing tool life and machining performance.

For manufacturers seeking dependable, high-performance NPT threading solutions, the 16IR11.5NPT insert stands as the trusted choice.

Previous page

Use equipment

CNC machining centre

CNC machine tools

Carved machine

Factory Board

Factory Board

Factory Board

Factory Board

Factory Board

Recommended products

FAQ

2025-05-29

The naming conventions for turning inserts generally follow international standards (such as ISO standards). The model number consists of a series of letters and numbers, each character representing different geometric parameters or functional characteristics, such as the naming convention for the TNMG160404R-PV turning insert from Lizhou.

2025-05-26

What types of end mills are there?

Materials can be processed according to different types of end mills, categorized by the types of milling tools, including flat end mills, ball end mills, radius end mills, chamfer end mills, and end mills with chip breakers.

2025-05-23

PCD milling cutter is a polycrystalline diamond (PCD) milling cutter, which has a wide range of applications in the field of machining.

2025-05-08

End mill for machining aluminum materials

Many customers have told us that ordinary end mills frequently stick when machining aluminum, and the accumulation of chips affects the accuracy, so they always change the tools. LIZHOU editor suggests that coated end mills are not recommended for aluminum materials, because some coatings contain aluminum elements. Therefore, it is better to choose uncoated end mills when selecting end mills for machining aluminum materials.