Blog

FAQ

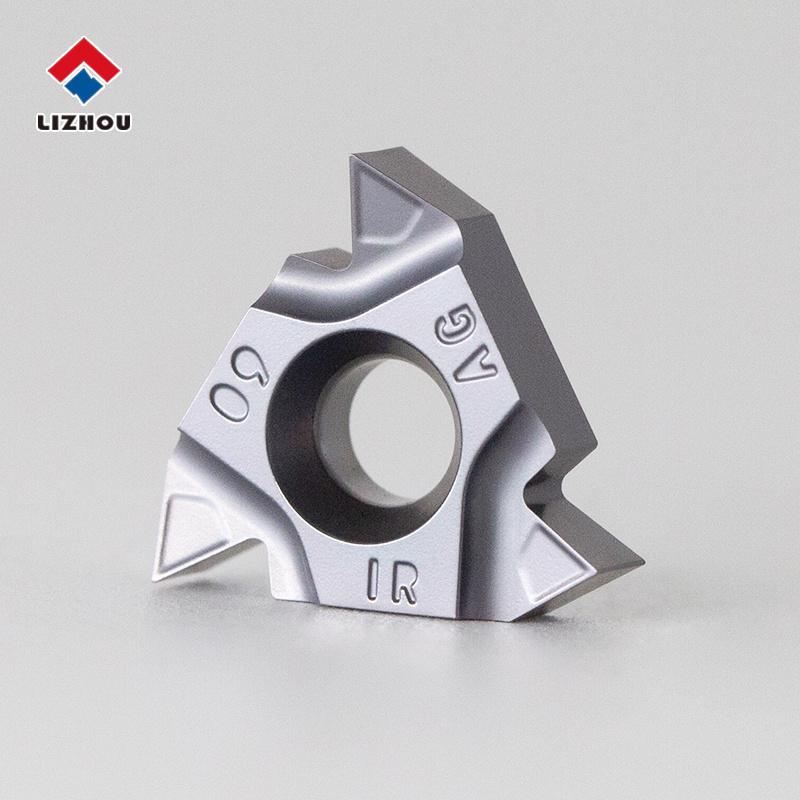

Metric ISO 60° External Thread Cutting Blades | Lizhou Cemented Carbide

Metric system ISO Threaded blade — A reliable choice for stable machining of metric threads

In mechanical machining, metric threads are the most widely used thread standard. Whether it's for equipment components, mold structural parts, or general-purpose mechanical fasteners, the machining quality of metric threads directly affects assembly accuracy and service life. For machining enterprises, a stable, durable metric thread cutting blade with standardized tooth profiles is an indispensable tool in daily production.

The metric system launched by Lizhou ISO Threaded blades are designed precisely around actual machining requirements and are specifically used for cutting. ISO Metric standard thread, with a thread angle of: 60 °, suitable for a variety of common machining materials, while ensuring thread quality, it also takes into account tool life and usage costs.

1. Specifically designed for metric standard threads, with precise and stable thread profiles.

Metric system ISO Threads have strict requirements for tooth profile angle, tooth height, and forming consistency.

Lizhou metric thread blades strictly adhere to the tooth profile grinding specifications. ISO Standards, ensure:

Thread profile is complete and angle is accurate.

Good pitch consistency

Stable go/no-go gauge testing

Batch processing ensures more uniform dimensions.

For long-term processing M For workshops dealing with threaded components, this stability can effectively reduce rework and scrap.

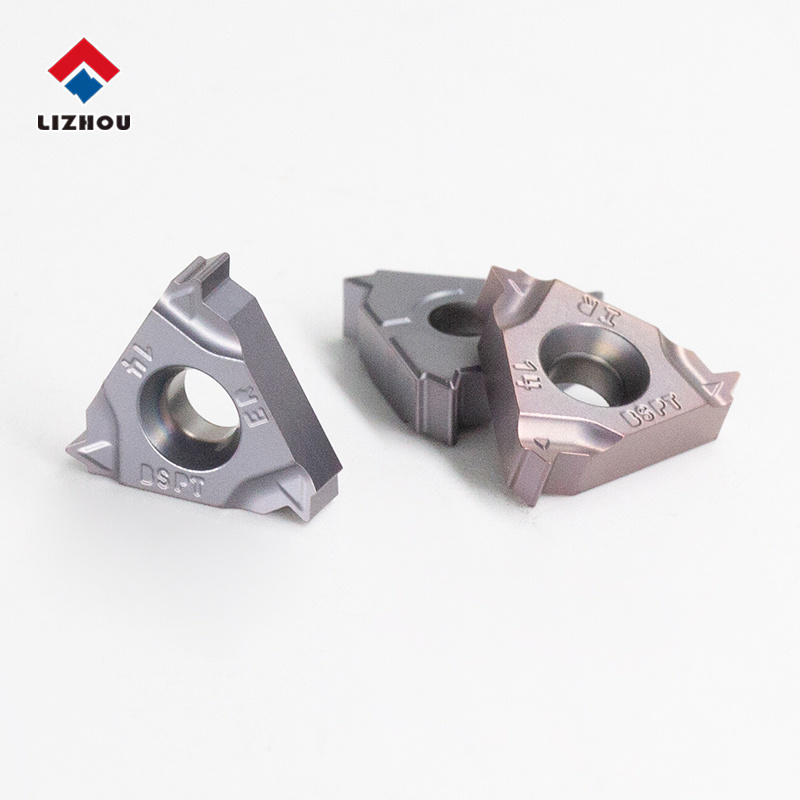

2. Indexable structure design to reduce tooling costs.

This series features a indexable thread-cutting blade design, and its multi-cutting-edge configuration is one of its major advantages.

In actual use:

After a single cutting edge wears out, it can be repositioned and continued in use.

No need to frequently replace the entire set of blades.

Higher blade utilization.

The cost per unit of processing is more controllable.

This design is ideally suited for production scenarios involving the mass processing of metric external threads.

3. Equipped with built-in chip-breaking grooves for smoother cutting.

During thread machining, chip control is crucial.

The Lizhou metric thread blade comes with an integrated chip-breaking groove that enables it to:

Effectively break chips

Reduce the occurrence of thread entanglement.

Reduce the cutting edge load.

Make the cutting process smoother.

Especially when machining steel and stainless steel, good chip-breaking performance can significantly enhance the machining experience.

4. High-quality tungsten steel material, balancing sharpness and wear resistance.

Lizhou consistently adheres to the use of high-quality tungsten steel materials and strictly controls the sintering and edge quality during blade manufacturing.

This enables metric thread blades to:

The blade is sharp and offers low cutting resistance.

Strong wear resistance

The cutting edge is stable and less likely to chip.

The threaded surface is smoother.

It can still maintain stable performance under continuous machining or long-tool-path conditions.

V. Provide corresponding grade selections tailored to different materials.

The requirements for threading blades vary significantly depending on the material.

Lizhou Metric ISO Threaded blades provide clear application guidelines for common machining materials:

Steel parts / Common stainless steel machining

For example: 16ER 2.50 ISO LMP303

Suitable for conventional machining, with stable cutting performance and balanced tool life.

Hardened steel parts / Hardened stainless steel machining

For example: 16ER 2.50 ISO LMP103

The blade tip has higher strength and is more suitable for materials with higher hardness.

This distinction makes it more intuitive for customers when selecting models and also enables better matching with actual machining conditions.

6. Primarily used for external thread machining, compatible with a variety of machine tools.

This series is primarily used for machining metric external threads and is suitable for common CNC lathes and related clamping systems.

Whether it's single-piece prototyping or mass production, excellent machining consistency can be maintained.

Common applications include:

External threads for mechanical parts

Equipment connection thread

Standard parts with threaded fittings

Threaded mold structural parts

7. Thirty-two years of dedicated focus on cemented carbides—driven solely by the pursuit of stable machining.

Lizhou Cemented Carbide has been deeply rooted in the industry for over three decades, rigorously controlling every stage of the process—from raw material selection to the shipment of finished blades.

For us, thread-cutting blades are not disposable products; rather, they are tools that must withstand repeated verification in real machining environments.

Stability, durability, and ease of use are our fundamental requirements for every metric-threaded blade.

If you’re looking for a metric threading insert with standard tooth geometry, stable cutting performance, and suitable for machining steel and stainless steel parts, LIZHOU Metric— ISO Threaded blades will be a practical and reliable choice.

It’s not exaggerated; yet it consistently delivers outstanding performance in everyday machining, making it the type of cutting tool that lasts long in the workshop and needs to be replaced infrequently.

Recommended products

16IR11BSPT British Standard Pipe Thread insert