Blog

FAQ

Versatile threading inserts suitable for a variety of internal and external thread operations | Lizhou Cemented Carbide

General-purpose threading tool It’s a truly hassle-free and cost-effective choice for thread machining.

In many manufacturing processes, threading is an indispensable step. Whether it’s for machining equipment components, pipe fittings connections, or structural assembly, the precision and stability of threads directly affect the final assembly quality. For many manufacturing companies, if each type of thread were to be equipped with a dedicated cutting tool, not only would management become complicated, but tool costs would also rise significantly.

Precisely for this reason, universal threading inserts are gradually becoming the preferred choice in an increasing number of machining workshops.

1. What are universal threading inserts? Why are they better suited for everyday machining?

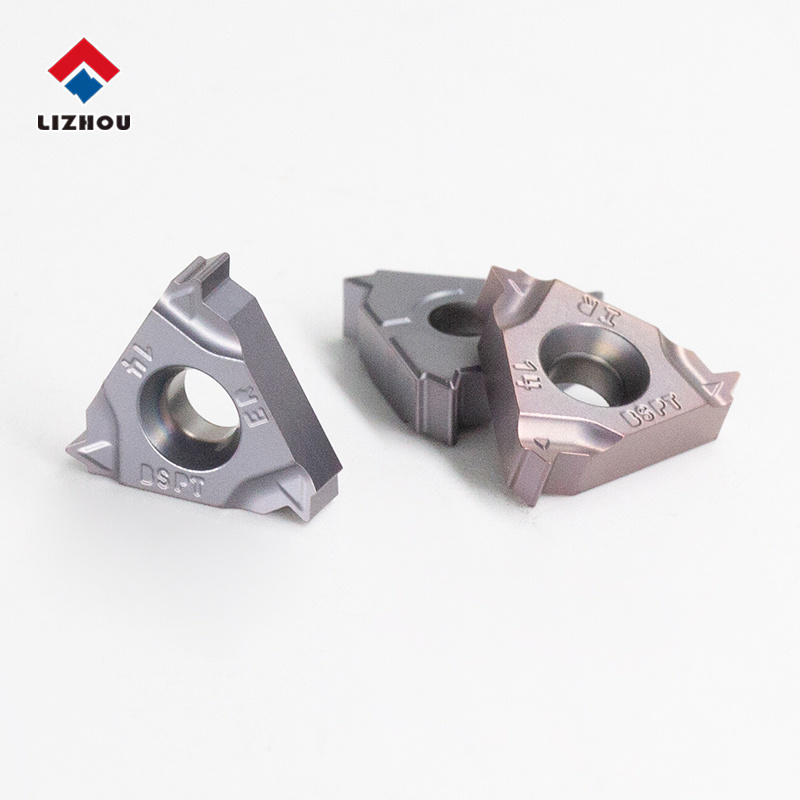

A universal threading insert is a indexable insert featuring a standardized thread profile design, making it suitable for a wide range of threading applications.

It can be used for both internal and external thread machining, is compatible with a wide range of common materials, and significantly reduces tooling costs while ensuring high thread quality.

For users who need to machine steel parts, stainless steel, and even certain hardened materials simultaneously, the versatility of these threading inserts offers a clear advantage.

II. Common tooth profile configurations, covering most machining requirements.

In practical use, the thread profile is the key factor determining the compatibility of threads. Lizhou’s universal threading inserts offer two commonly used thread profile options:

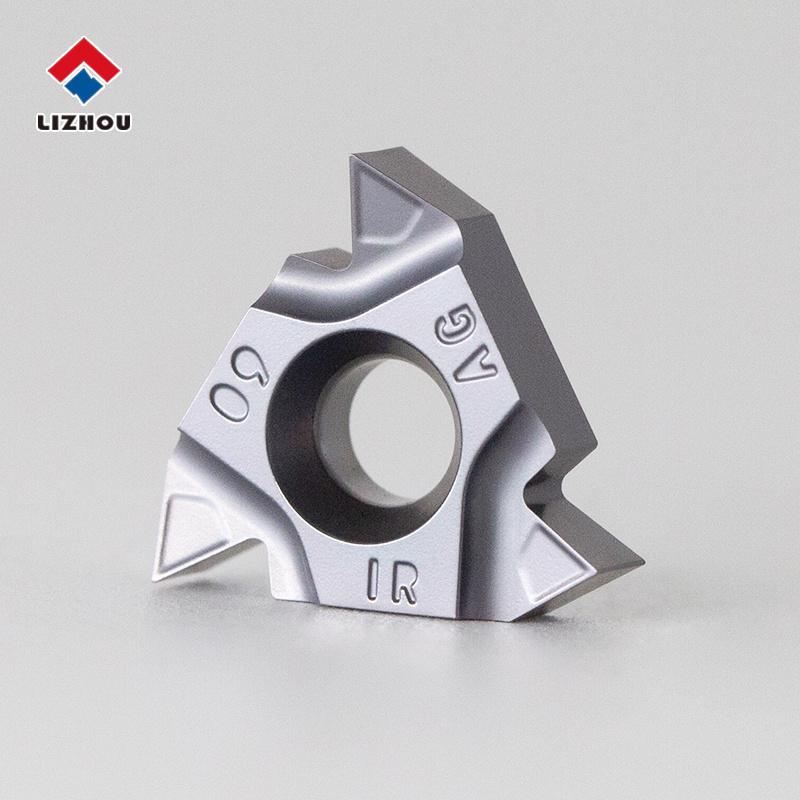

60 °Tooth profile

Mainly used for internal thread machining.

Suitable for common materials such as steel and stainless steel.

Thread forming is stable, and the tooth profile has good consistency.

Commonly used for machining equipment parts and standard fasteners.

55 °Tooth profile

More suitable for external thread machining

Better adaptability to hardened steel parts and hardened stainless steel.

The blade tip has high strength and even stronger resistance to chipping.

Suitable for applications that demand high-quality thread appearance and durability.

By carefully selecting the tooth profile, a single set of blades can cover a variety of machining conditions, reducing time losses caused by frequent tool changes.

3. The cutting edge is sharp and wear-resistant, ensuring more stable thread formation.

Thread machining places extremely high demands on the cutting edge of the insert. Once the cutting edge wears down or chews, thread accuracy is the first to be affected.

The Lizhou universal threading blade places greater emphasis on practical performance in its cutting edge design:

The blade is sharp and offers low cutting resistance.

The thread profile is clear and not easily marred.

The cutting process is smoother, reducing vibration.

Good thread size consistency, low rework rate.

Whether processing individual parts or engaging in mass production, it can maintain good stability.

4. Adaptable to a variety of materials, offering greater processing flexibility.

In many machining environments, the types of materials are often quite diverse. The advantage of universal threading inserts lies in their versatility—they can handle a wide variety of jobs and are suitable for:

Carbon steel, alloy steel

Ordinary stainless steel

Partially hardened steel parts

Hardened stainless steel material

For small- and medium-sized processing plants or multi-product processing workshops, this material adaptability can significantly reduce the pressure on tool inventory.

V. The versatility not only brings convenience but also cost advantages.

From the customer’s perspective, the biggest advantage of choosing universal threading inserts isn’t just that they’re “usable”—it’s that they’re more convenient and cost-effective.

A blade that covers multiple threading scenarios.

Tool inventory made simpler.

Reduced tool change frequency

Higher blade utilization.

The cost per unit of processing is more controllable.

In long-term production, this cost advantage will become increasingly apparent.

Sixth, 32 years of persistence—just to ensure the blades last.

Lizhou Cemented Carbide has been deeply rooted in the industry for over three decades, consistently upholding stringent standards in raw material selection, manufacturing processes, and quality control.

Each thread-cutting blade is designed with practical machining needs in mind, focusing on stability, durability, and ease of use—rather than just theoretical specifications.

For processing companies, whether a cutting tool is reliable often depends on time-tested performance. Itzhou has precisely earned the trust of many customers as a long-term partner thanks to its consistently stable product performance.

Conclusion

If you’re looking for a threading blade that has a wide range of applications, low operating costs, and stable thread quality, a universal threading blade would be a very practical choice.

Lizhou thread-cutting blades are worth gradually verifying in actual machining operations.

Recommended products