Blog

FAQ

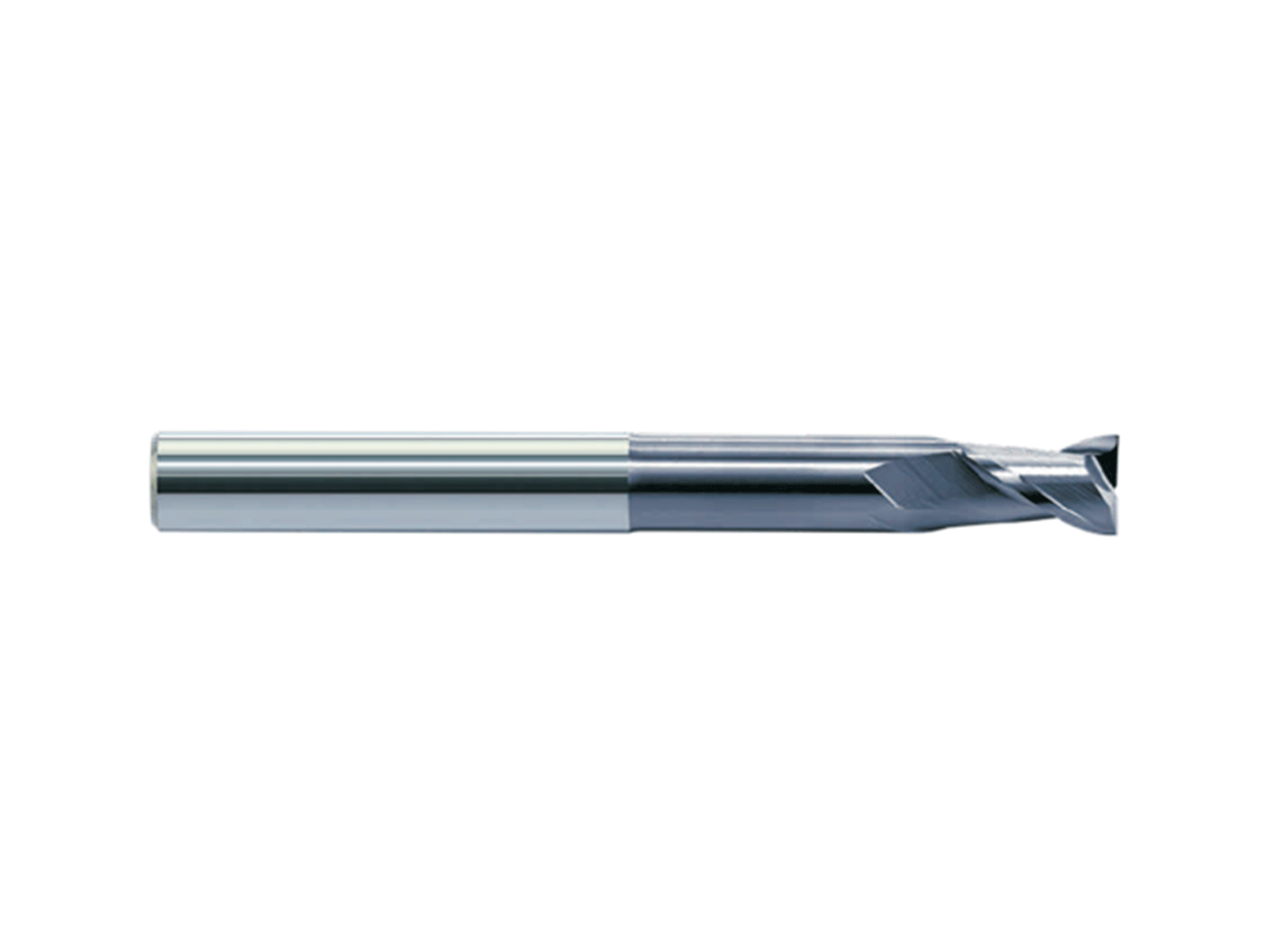

Stainless steel machining tungsten steel 65-degree 4-flute flat-end end mill

When machining stainless steel, tool selection has always been a challenge for machining workshops.

Stainless steel exhibits characteristics such as high toughness, tendency to stick to the cutting tool, and poor thermal conductivity. During machining, this material easily generates high temperatures and builds up built-up edges, leading to rapid tool wear, poor surface roughness, and unstable machining dimensions. Particularly in mass production, if the cutting tools lack sufficient stability, both production efficiency and machining quality will be significantly compromised.

The stainless steel-specific product introduced today 65 degree 4 Flat-end face milling cutter Made from high-quality tungsten steel bars, featuring an optimized groove design and suitable for... HRC60 The following stainless steel geometries can effectively enhance machining speed, surface finish, and tool life, making them a highly reliable tool choice for stainless steel machining workshops.

I. Ultra-fine-grained tungsten steel bar stock + Isostatic pressing makes the cutting tools more wear-resistant and more stable.

The tool substrate determines whether the tool can maintain sharpness and strength during prolonged cutting. This series features:

Ultrafine-grained cemented carbide powder

Dry Bag Isostatic Pressing Process CIP )

This process makes the tool substrate denser and more uniform, endowing it with: better toughness, stronger resistance to chipping, higher hardness and wear resistance, and a longer service life.

For processing ≤ HRC60 stainless steel (such as 304、316、420、431 etc.), which can effectively resist the high heat and impact generated during cutting.

2. The four-blade cutter head design offers greater rigidity and more stable machining.

In stainless steel machining, vibration is a major factor affecting machining quality.

The four-blade design offers the following advantages:

The tool has higher overall rigidity and is less prone to chatter.

Smooth toolpaths and stable machining dimensions.

The blade pattern is finer and has higher smoothness.

Cutting load is distributed more evenly, resulting in longer tool life.

Particularly suitable for: side milling, surface machining, contour machining, step machining, and right-angle groove cutting.

3. The double-edged (double-guided edge) design ensures greater dimensional accuracy and smoother machining.

Stainless steel machining is prone to issues such as tool wandering, rough side walls, and dimensional deviations.

The double-edged band can effectively address these pain points:

The tool and workpiece are guided more stably.

The cutting path is smoother.

The sidewall is straighter, with tighter tolerances.

Significantly reduce the occurrences of "biting the knife" and "knife vibration."

Particularly suitable for machining mechanical parts and mold components with high dimensional accuracy requirements.

Four, You U The groove structure makes chip removal easier and prevents chips from sticking to the tool.

Stainless steel cutting tends to produce long, thin, and highly ductile chips. If these chips are not discharged smoothly, they can:

Scratch the workpiece surface.

Increase the cutting temperature

Accelerate tool wear

Increased risk of chipping

You U Advantages of the groove structure: smoother chip evacuation, reduced buildup of built-up edge, lower cutting temperature, lighter cutting load on the tool, and more stable machining of stainless steel.

V. Suitable for a wide range of stainless steel processing applications

This model 65 degree 4 Blade-end milling cutters can be used for:

304/316 Stainless steel profile machining

Stainless Steel Cavity Groove Machining

Precision structural component machining

Semi-finishing of mold steel

Medical device component machining

High-gloss side milling

Both high-speed machines and machining centers can deliver stable performance.

6. Comprehensive specifications, supporting various non-standard customizations.

Lizhou can provide:

Different blade diameters, blade lengths, and shank diameters

Long blade / Extended-handle customizations

Special coating

Special blade edge treatment

OEM/ODM

Whether you're machining thin-walled parts, deep slots, or high-hardness materials, you can always find a suitable tool.

7. Why do customers choose Lizhou Stainless Steel? 65 A four-flute end mill?

The tool is less likely to chip and has a longer lifespan.

High surface finish, fine knife marks.

Chip removal is smooth and does not stick to the blade.

More stable during machining, less likely to jump.

The finished product has stable and reliable dimensions.

Excellent value for money

Supports customization, with greater versatility.

For companies that engage in long-term stainless steel processing, this is a reliable tool that can significantly enhance processing efficiency.

Recommended products