Blog

Lathe tooling solutions: efficient machining, precise cutting

Whether it's metal turning, precision parts machining, or high-volume production tasks, the choice of turning inserts and lathe inserts directly determines machining efficiency and product quality.

We offer world-leading turning inserts and matching tool holders, covering the processing needs of various materials such as stainless steel, alloy steel, cast iron, and titanium alloys, helping you easily cope with complex working conditions!

Recommended Turning Tool Products: Carbide Inserts + High-rigidity Tool Holder Combination

1、CNMG 120408 Negative Rake Inserts

Applicable Scenarios : Rough machining and semi-finishing of stainless steel and high-temperature alloys.

Core Advantages :8 The cutting edge design significantly reduces the cost per edge, and with a wear-resistant coating, the lifespan is increased 30% above.

Recommended Tool Holder : SCLCR 2525M12 ,The high-rigidity structure ensures stability in heavy cutting.

2、WNMG 080408 Multifunctional Inserts

Applicable Materials : Cast iron, carbon steel, and non-metallic composite materials.

Performance Highlights :6 Economical cutting edge design, combined with chip breaker technology, compatible with intermittent cutting and continuous machining.

Matching Tool Holder : DSRNR 2525M12 ,Suitable for external cylindrical, end face, and profile turning.

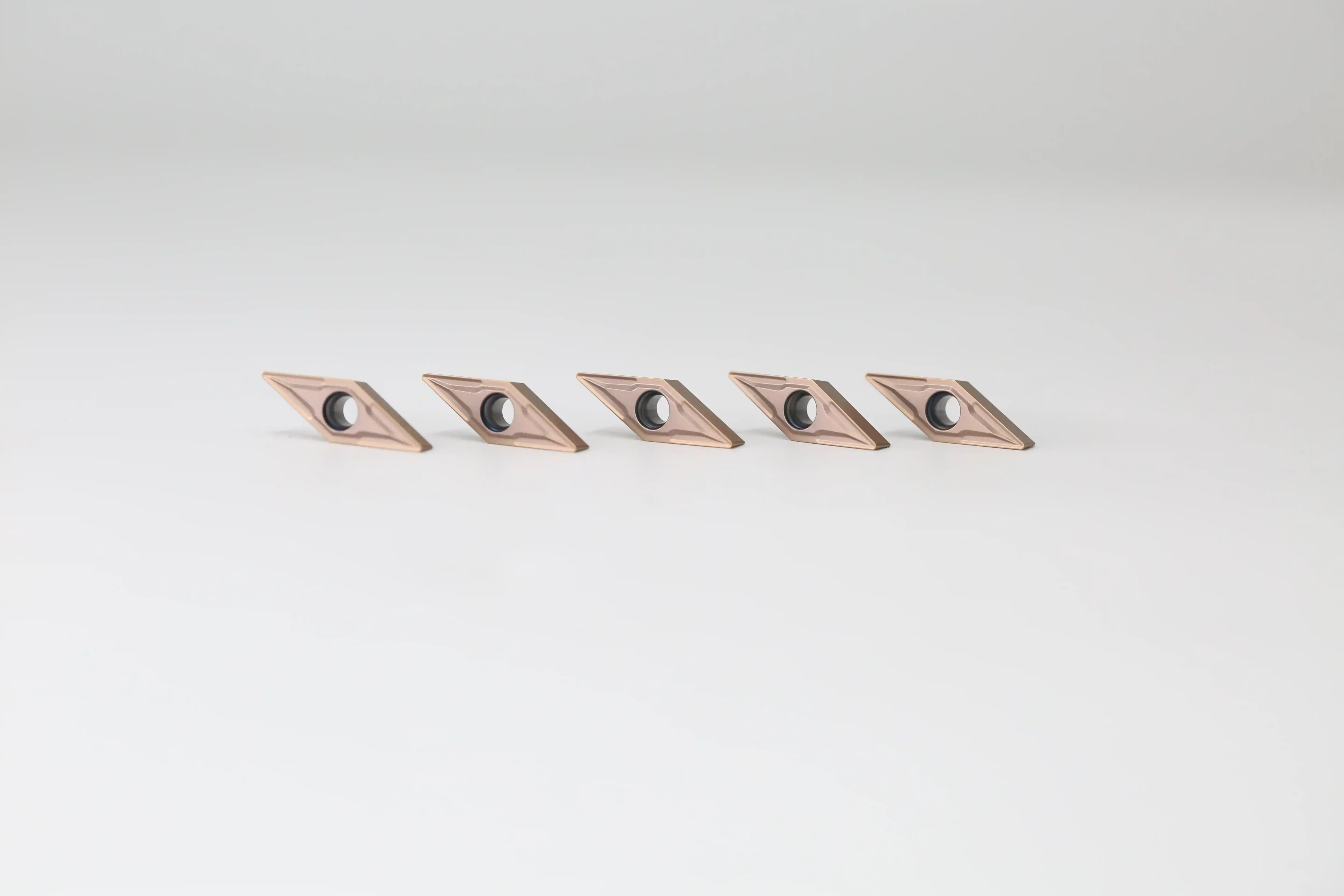

3、VBMT 160404 Finishing Inserts

Precision Field : High-gloss finishing of titanium alloys and aluminum alloys.

Technological Breakthrough : Ultra-fine grain carbide substrate, combined with TiAlN coating, surface roughness can reach Ra0.4μm 。

Tool Holder Solution : SVJBL 2525M16 ,Negative rake design reduces vibration and improves tool life.

Why Choose Our Turning Tools?

Extra-long Durability : Using CVD/PVD composite coating technology, the anti-chipping ability is improved 50% ,stable performance under extreme temperatures .

Multi-scenario Adaptability : From heavy-duty roughing to micron-level finishing, the full range of insert specifications covers ISO standards and customized needs.

Cost Optimization : Through the upgrade of the number of cutting edges and quick-change design, the unit processing cost is reduced by up to 40%。

Our carbide turning inserts are widely used in automotive manufacturing, aerospace, and mold machining, and have gained industry recognition for their excellent cutting performance. Whether you need general-purpose inserts or customized solutions, our engineering team will accurately match the tool system for you.

Recommended products