Product

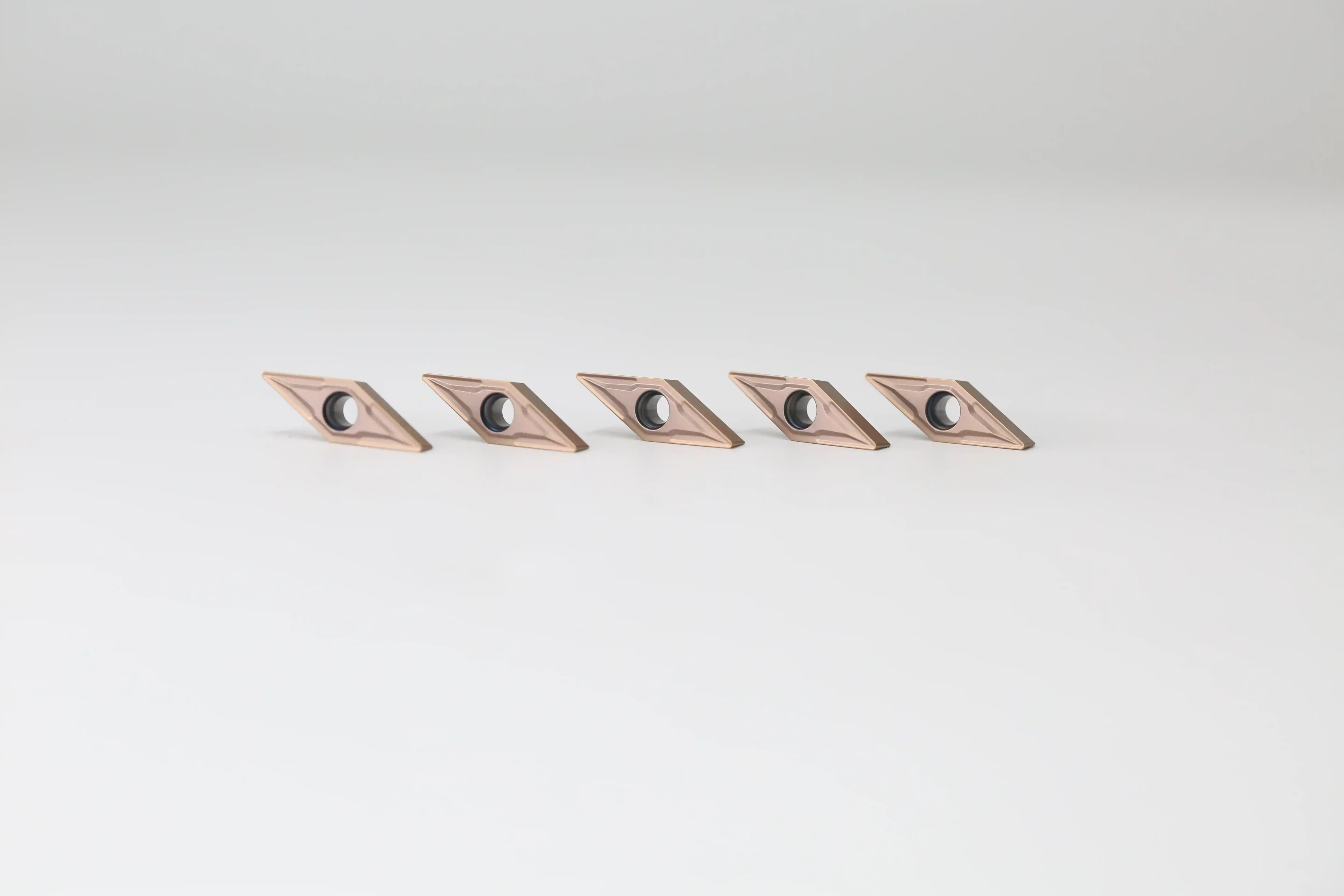

DCMT-MV general turning blade

China Lizhou Hard Alloy Source Factory

Product Name:Steel General Turning Inserts

Coating : PVD

Brand number:LMP202

Classification :

Turning insert

keyword:

lizhou

DCMT070202-MV and DCMT11T304 Carbide Turning Inserts: Precision, Durability, and Performance in Metal Cutting

Introduction

In modern precision engineering, cutting tool inserts are essential to achieving productivity, accuracy, and surface quality. Among the most popular designs are DCMT carbide inserts, recognized for their versatility in turning operations, especially where accuracy and fine surface finish are critical.

Our company, a specialized carbide insert manufacturer, produces DCMT070202-MV and DCMT11T304 inserts for global machining markets. These products combine robust tungsten carbide substrates with advanced coatings, ensuring long tool life and optimized performance across multiple industries.

This article explores their performance advantages, ISO nomenclature meaning, dimensions, applications, features, precautions, and innovations—helping engineers, buyers, and machinists understand why DCMT inserts are an excellent investment.

Type | Basic Dimensions (mm) | Cutting Data | PVD | CVD | |||||

I.C | S | D | R | Cutting Depth (mm) | Feed ( mm/tooth ) | LMP202 | LKC202 | LPC202 | |

DCMT 070202-MV | 6.35 | 2.38 | 2.80 | 0.2 | 0.20-2.30 | 0.05-0.10 | ⚪ |

|

|

DCMT 070204-MV | 6.35 | 2.38 | 2.80 | 0.4 | 0.40-2.30 | 0.05-0.20 | ⚪ |

|

|

DCMT 070208-MV | 6.35 | 2.38 | 2.80 | 0.8 | 0.80-2.30 | 0.10-0.35 | ⚪ |

|

|

DCMT 11T304-MV | 9.525 | 3.97 | 4.40 | 0.4 | 0.40-2.30 | 0.05-0.20 | ⚪ |

|

|

DCMT 11T308-MV | 9.525 | 3.97 | 4.40 | 0.8 | 0.80-2.30 | 0.10-0.35 | ⚪ |

|

|

DCMT 070204 | 6.35 | 2.38 | 2.80 | 0.4 | 1.00-2.00 | 0.10-0.25 | ⚪ |

|

|

DCMT 070208 | 6.35 | 2.38 | 2.80 | 0.8 | 1.00-2.00 | 0.10-0.25 | ⚪ |

|

|

DCMT 11T304 | 9.525 | 3.97 | 4.40 | 0.4 | 1.00-3.00 | 0.10-0.30 | ⚪ |

|

|

DCMT 11T308 | 9.525 | 3.97 | 4.40 | 0.8 | 1.00-3.00 | 0.10-0.30 | ⚪ |

|

|

1. Advantages of Carbide Turning Inserts

Compared to traditional high-speed steel (HSS) or uncoated tools, carbide inserts like DCMT070202-MV and DCMT11T304 provide unmatched performance benefits:

High Hardness and Strength

Tungsten carbide substrates maintain hardness even at high cutting speeds, improving productivity.

Wear and Heat Resistance

Multilayer CVD or PVD coatings extend tool life and withstand extreme cutting conditions.

Dimensional Accuracy

Inserts are manufactured under strict ISO tolerances, enabling consistent performance in automated production lines.

Economical Cutting Solution

Each insert features multiple cutting edges, reducing cost-per-part and eliminating tool resharpening.

Surface Finish Quality

Especially in DCMT designs, the insert geometry supports stable chip control, ensuring smooth finishes even at high feed rates.

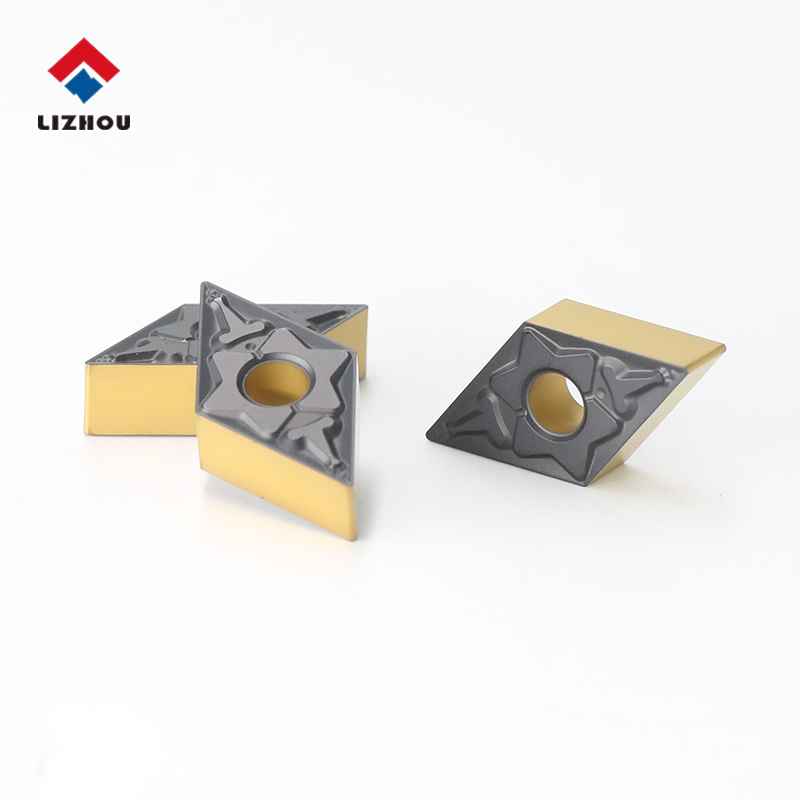

2. Decoding the DCMT Nomenclature

Both DCMT070202-MV and DCMT11T304 conform to ISO standard insert coding. Each letter and number provides key information about insert geometry and specifications.

Letter Designation – DCMT

D = Shape: 55° rhombic diamond insert, ideal for profiling, contour turning, and finishing.

C = Relief Angle: 7° clearance, reducing friction and preventing workpiece rubbing.

M = Tolerance Class: Medium tolerance, balancing accuracy with production economy.

T = Insert Type: Single-sided insert with hole, secured by screw or clamp for stability.

Numerical Codes

DCMT070202-MV

07 = Cutting edge length (~7.94 mm).

02 = Insert thickness (~2.38 mm).

02 = Nose radius (0.2 mm) for ultra-fine finishing.

MV = Chipbreaker style, optimized for finishing to medium turning operations.

DCMT11T304

11 = Cutting edge length (~11 mm).

T3 = Insert thickness (~3.97 mm).

04 = Nose radius (0.4 mm), suitable for general finishing and semi-finishing.

3. Performance Analysis

DCMT070202-MV – Precision Finishing Insert

Strengths: Small nose radius and sharp cutting edge for fine finishing.

Applications: Precision turning of automotive, aerospace, and medical components where surface roughness < Ra 1.6 μm is required.

Benefit: Superior chip control at low feed rates, minimizing tool marks and vibration.

DCMT11T304 – General Finishing Insert

Strengths: Larger size and stronger cutting edge compared to DCMT070202-MV.

Applications: Semi-finishing and light roughing in steel, stainless steel, and cast iron.

Benefit: Balances tool life and surface finish, making it ideal for medium-duty turning.

4. Typical Application Scenarios

Both inserts are widely used in industries where precision and repeatability are key:

Automotive Manufacturing

Turning of engine shafts, pistons, brake discs, and housings.

High-speed finishing of hardened steels and alloy parts.

Aerospace Engineering

Machining titanium, Inconel, and stainless steels for aircraft components.

Precision contour turning where accuracy is critical.

Medical Equipment

High-precision machining of surgical tools and orthopedic implants.

General Engineering

Fine turning of gears, hydraulic parts, and industrial rollers.

Semi-finishing of cast iron housings and structural steel parts.

5. Key Features

55° Diamond Geometry: Provides both strength and flexibility for profiling and finishing.

Multiple Cutting Edges: Each insert can be indexed for extended life and reduced tooling costs.

Optimized Chipbreaker (MV): Designed for smooth chip evacuation and reduced cutting forces.

Surface Finish Optimization: Small nose radii minimize tool marks while maintaining edge strength.

Compatibility: Fits most standard ISO toolholders, reducing procurement complexity.

6. Precautions for Use

To maximize performance and extend insert life, operators should observe the following:

Clamping Stability

Ensure the insert is seated properly in the toolholder. Loose clamping may lead to vibration and premature failure.

Correct Cutting Parameters

DCMT070202-MV: Use low feed and depth of cut for finishing.

DCMT11T304: Supports slightly higher feeds for semi-finishing.

Coolant Use

Dry cutting may be acceptable in cast iron.

Use coolant when machining stainless steel or heat-resistant alloys to prevent thermal cracks.

Avoid Shock Loads

Carbide inserts are hard but brittle; avoid heavy interruptions or unstable setups.

Insert Rotation

Index all usable cutting edges before replacing the insert to optimize cost efficiency.

7. Technological and Patent Innovations

Our company invests in R&D to improve carbide insert performance:

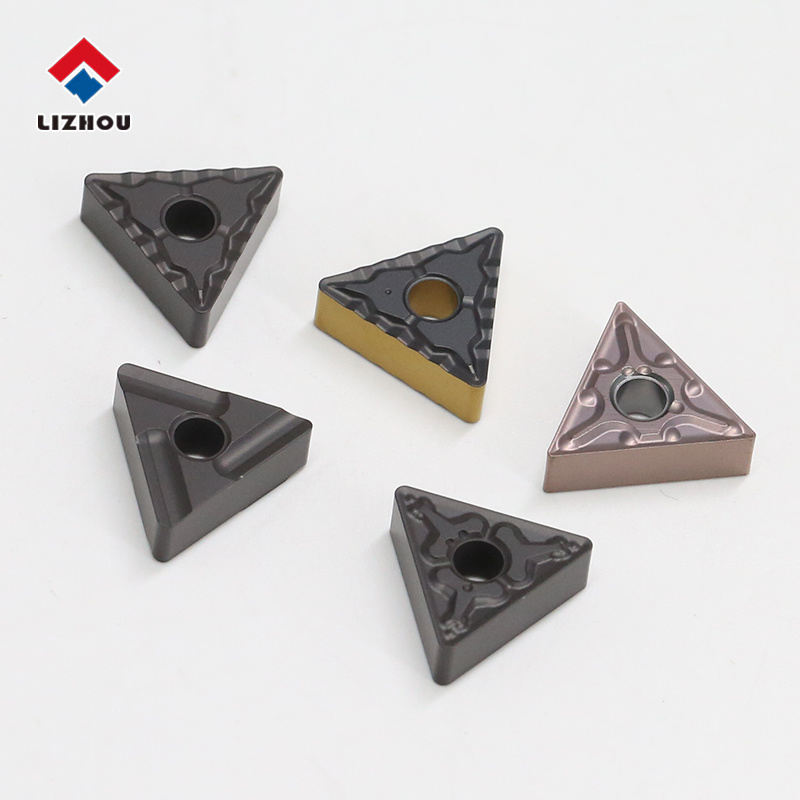

Advanced Coatings

CVD TiCN + Al2O3 multilayer coatings for steel and cast iron.

PVD TiAlN coatings for stainless steels and heat-resistant alloys.

Substrate Engineering

Nano-grain carbide substrates improve toughness while maintaining hardness.

Optimized Chipbreaker Geometry

Proprietary designs minimize chip clogging and heat generation, ensuring consistent tool life.

Precision Manufacturing

Inserts are ground to ISO tolerances, guaranteeing repeatable accuracy across batches.

8. Why Choose Our DCMT Inserts?

As a hard alloy (carbide) manufacturer, we provide both standardized and customized solutions:

Direct Factory Supply: Competitive prices without middleman costs.

Wide Range of Grades: Coatings and substrates tailored for steels, cast irons, and exotic alloys.

Global Service: Serving automotive, aerospace, oil & gas, and engineering clients worldwide.

Innovation-Driven: Continuous R&D ensures cutting-edge chip control and extended tool life.

Conclusion

The DCMT070202-MV and DCMT11T304 carbide turning inserts represent the perfect balance of precision, durability, and cost-effectiveness.

DCMT070202-MV excels in ultra-precision finishing, delivering outstanding surface quality.

DCMT11T304 is a versatile finishing-to-semi-finishing insert, offering strength and efficiency for medium-duty applications.

By integrating advanced coatings, optimized chipbreaker designs, and robust carbide substrates, these inserts ensure stable performance, reduced tool costs, and superior machining results.

For manufacturers aiming to improve productivity and quality in turning operations, our DCMT series carbide inserts are the ultimate choice.

Previous page

Next page

Use equipment

CNC machining centre

CNC machine tools

Carved machine

Factory Board

Factory Board

Factory Board

Factory Board

Factory Board

Recommended products

FAQ

2025-05-29

The naming conventions for turning inserts generally follow international standards (such as ISO standards). The model number consists of a series of letters and numbers, each character representing different geometric parameters or functional characteristics, such as the naming convention for the TNMG160404R-PV turning insert from Lizhou.

2025-05-26

What types of end mills are there?

Materials can be processed according to different types of end mills, categorized by the types of milling tools, including flat end mills, ball end mills, radius end mills, chamfer end mills, and end mills with chip breakers.

2025-05-23

PCD milling cutter is a polycrystalline diamond (PCD) milling cutter, which has a wide range of applications in the field of machining.

2025-05-08

End mill for machining aluminum materials

Many customers have told us that ordinary end mills frequently stick when machining aluminum, and the accumulation of chips affects the accuracy, so they always change the tools. LIZHOU editor suggests that coated end mills are not recommended for aluminum materials, because some coatings contain aluminum elements. Therefore, it is better to choose uncoated end mills when selecting end mills for machining aluminum materials.