Product

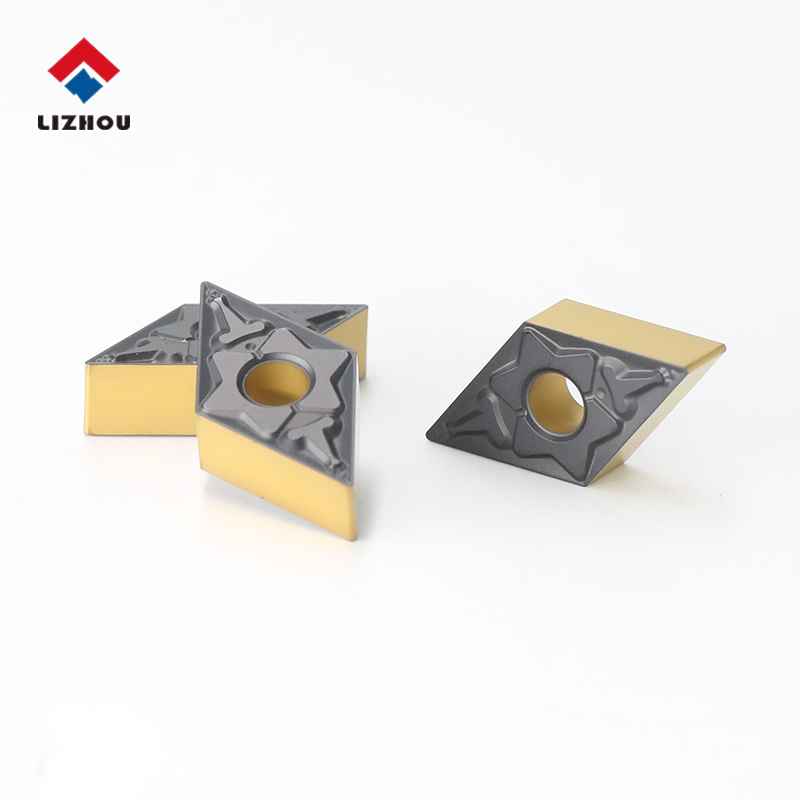

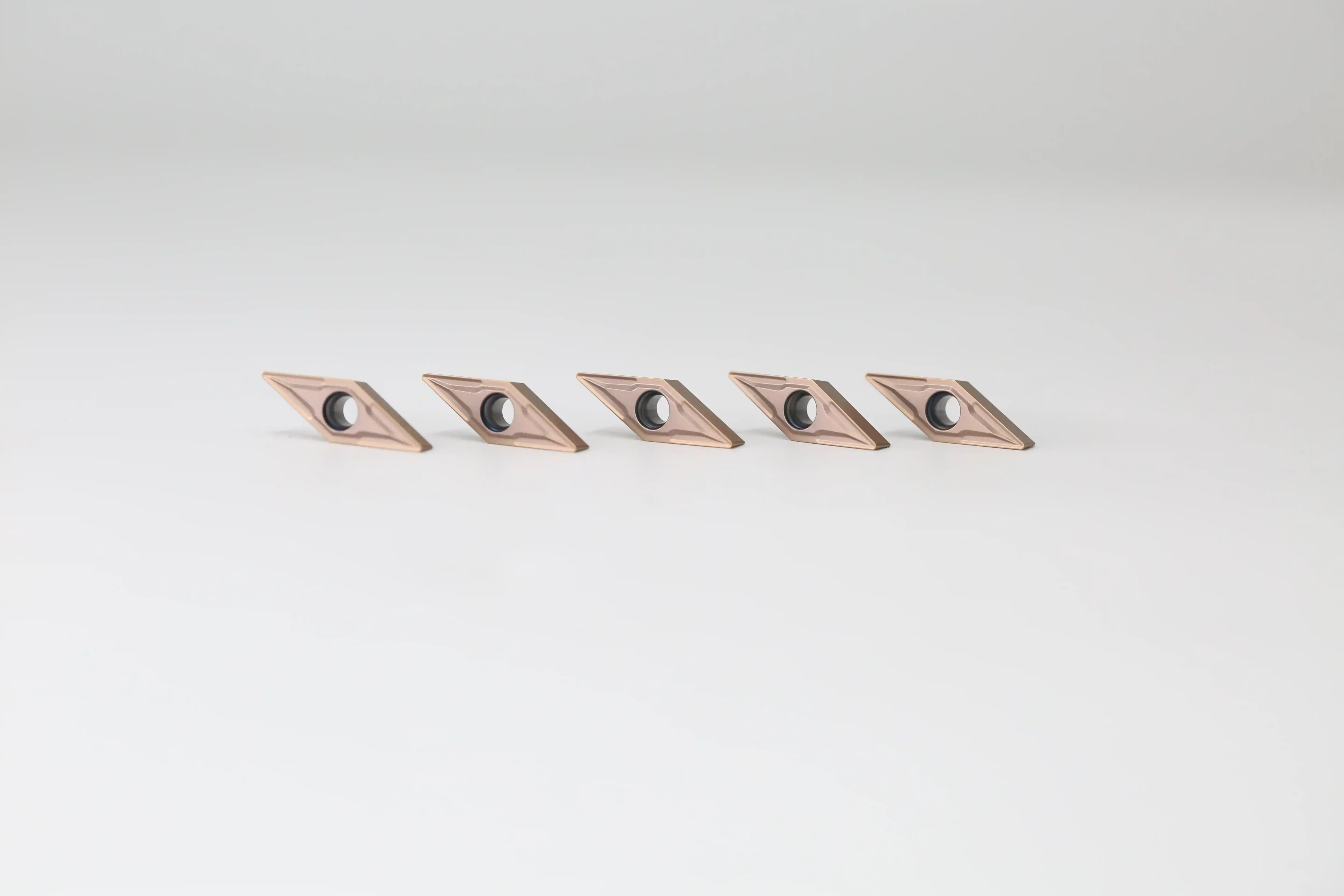

VBMT-General turning Insert

China Lizhou Hard Alloy Source Factory

Product Name:Steel Turning Inserts

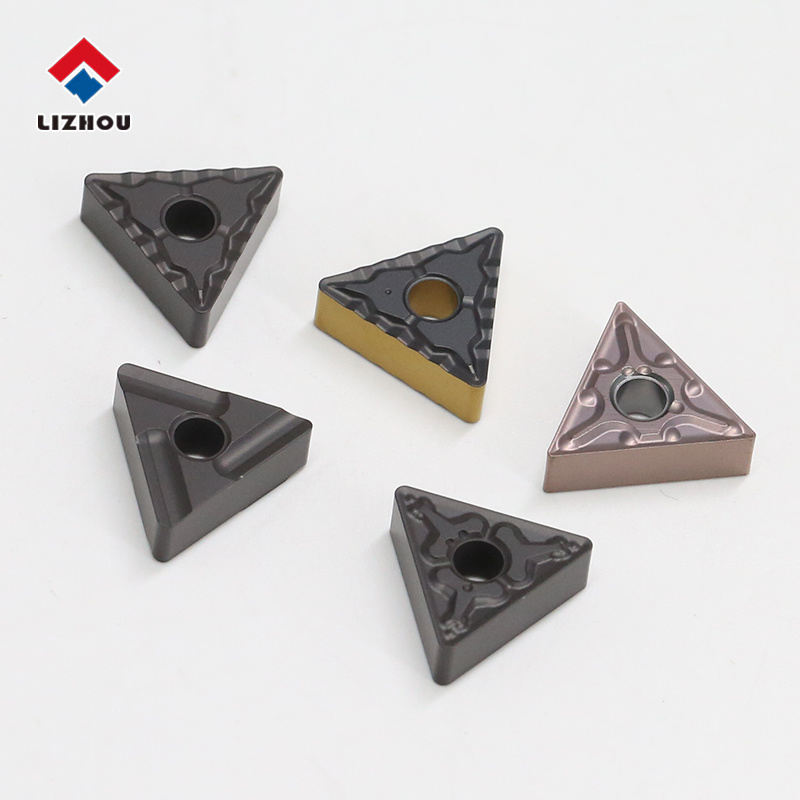

Coating : PVD

Brand number:LMP202

Classification :

Turning insert

keyword:

lizhou

VBMT110304 & VBMT160404 Carbide Turning Inserts – Precision, Performance, and Reliability

Introduction

In modern machining, precision and productivity depend heavily on the quality of cutting tools. Carbide turning inserts have become indispensable in industries ranging from automotive and aerospace to general engineering. Among the most popular and widely applied geometries are VBMT110304 and VBMT160404, two high-performance carbide inserts engineered for efficient metal turning.

As a professional carbide manufacturer, we design and produce these inserts with advanced powder metallurgy, innovative coatings, and rigorous quality control. This article provides a comprehensive analysis of VBMT110304 and VBMT160404 inserts, covering performance advantages, coding interpretation, applications, unique features, precautions, and patented innovations.

Type | Basic Dimensions (mm) | Cutting Data | PVD | ||||

I.C | S | D | R | Cutting Depth (mm) | Feed ( mm/tooth ) | LMP202 | |

VBMT 110304 | 6.35 | 3.18 | 2.80 | 0.4 | 0.50-2.00 | 0.05-0.25 | ⚪ |

VBMT 110308 | 6.35 | 3.18 | 2.80 | 0.8 | 0.50-2.00 | 0.05-0.25 | ⚪ |

VBMT 160404 | 9.525 | 4.76 | 4.40 | 0.4 | 1.00-3.00 | 0.07-0.25 | ⚪ |

VBMT 160408 | 9.525 | 4.76 | 4.40 | 0.8 | 1.00-3.00 | 0.07-0.25 | ⚪ |

1. Advantages of Carbide Inserts

Carbide turning inserts, such as VBMT110304 and VBMT160404, outperform traditional high-speed steel tools due to:

High Hardness and Wear Resistance – Submicron carbide substrates combined with advanced coatings (CVD/PVD) allow machining of hardened steels, stainless steel, cast iron, and superalloys.

Thermal Stability – Carbide maintains cutting edge integrity at temperatures exceeding 800°C, reducing tool wear in high-speed machining.

Cost Efficiency – Indexable inserts reduce downtime since they can be quickly replaced without resharpening, improving tool life and productivity.

Surface Finish Quality – Optimized chip breakers provide smooth cutting action, minimizing vibration and ensuring better surface roughness.

Versatility – A single insert geometry can handle multiple operations: roughing, finishing, profiling, and facing.

2. Decoding VBMT Insert Code

The ISO insert designation, such as VBMT110304 or VBMT160404, follows a standardized coding system:

V – Insert shape: 55° rhombic diamond (excellent for finishing and profiling).

B – Clearance angle: 5° relief, reducing cutting resistance.

M – Tolerance class: Medium precision (±0.05 mm, ±0.13°).

T – Insert type: Single-sided with hole for clamping.

Now let’s decode the numerical values:

For VBMT110304:

11 – Insert size (inscribed circle ≈ 11 mm).

03 – Insert thickness (≈ 3.97 mm).

04 – Nose radius (0.4 mm), ensuring precise finishing.

For VBMT160404:

16 – Insert size (inscribed circle ≈ 16 mm).

04 – Insert thickness (≈ 4.76 mm).

04 – Nose radius (0.4 mm), suitable for fine finishing while maintaining strength.

📌 Interpretation:

VBMT110304 is a smaller insert, ideal for precision finishing in tight spaces.

VBMT160404 is larger, offering more edge strength and durability for medium turning tasks.

3. Performance Analysis

(1) Cutting Edge Geometry

Sharp edge with positive rake angle, reducing cutting forces and energy consumption.

Chip breakers designed for stainless steel and alloy steels, preventing built-up edge formation.

(2) Substrate & Coating Technology

Nano-grain carbide substrate improves toughness and reduces fracture risk.

PVD coatings (TiAlN, AlTiN, or TiCN) enhance wear resistance, especially at high speeds.

Advanced CVD multilayer coatings provide superior performance in cast iron and steel turning.

(3) Machining Benefits

Excellent for finishing operations due to small nose radius (0.4 mm).

Capable of light to medium turning with consistent tool life.

Reduces vibration in slender workpieces, ensuring smoother surface finish.

4. Application Scenarios

VBMT110304 and VBMT160404 inserts are widely used in:

Automotive Industry

Machining engine parts, crankshafts, and shafts with precise surface finish.

Aerospace Industry

Turning of heat-resistant alloys (Inconel, titanium) with minimal tool wear.

General Engineering

Precision turning of stainless steel, alloy steel, and hardened materials.

Medical Device Manufacturing

Ideal for finishing surgical instrument components requiring tight tolerances.

Energy Industry

Used in machining valves, pumps, and turbine components.

5. Key Features

High Precision Finishing – 0.4 mm nose radius ensures fine detail turning.

Low Cutting Forces – Positive rake angle reduces power consumption.

Versatility – Suitable for both internal and external turning.

Long Tool Life – Optimized carbide grade balances toughness and hardness.

Anti-Chipping Technology – Reinforced edge prevents premature breakage.

Surface Quality – Produces Ra < 1.6 µm on most steels.

6. Precautions for Use

To maximize insert life and performance:

Correct Clamping – Ensure inserts are mounted securely to avoid vibration.

Optimal Cutting Parameters – Use manufacturer-recommended cutting speed, feed rate, and depth of cut.

VBMT110304: Best for light finishing (ap < 1.5 mm, f < 0.15 mm/rev).

VBMT160404: Suitable for medium turning (ap < 2.5 mm, f < 0.25 mm/rev).

Coolant Usage – Apply coolant to reduce thermal cracks, especially for stainless steel machining.

Chip Control – Monitor chip flow to avoid entanglement and surface damage.

Avoid Overloading – These inserts are designed for precision, not heavy roughing.

7. Technical & Patent Innovations

As a hard alloy manufacturer, our VBMT series benefits from continuous R&D:

Nano-Coating Technology – Patented PVD coating increases wear resistance by 30%.

Hybrid Substrate – Fine-grain tungsten carbide with cobalt binder for balanced toughness.

Edge Preparation – Micro-honing ensures sharp yet durable edges.

Cryogenic Treatment – Enhances carbide grain stability for extended tool life.

Sustainable Manufacturing – Recycling technology reduces material waste in insert production.

8. Comparison Between VBMT110304 & VBMT160404

| Feature | VBMT110304 | VBMT160404 |

|---|---|---|

| Insert Size | 11 mm | 16 mm |

| Thickness | 3.97 mm | 4.76 mm |

| Nose Radius | 0.4 mm | 0.4 mm |

| Best Application | Precision finishing in small parts | Medium turning, longer tool life |

| Rigidity | Medium | Higher |

| Typical Industry Use | Medical, electronics | Automotive, aerospace |

Previous page

Next page

Use equipment

CNC machining centre

CNC machine tools

Carved machine

Factory Board

Factory Board

Factory Board

Factory Board

Factory Board

Recommended products

FAQ

2025-05-29

The naming conventions for turning inserts generally follow international standards (such as ISO standards). The model number consists of a series of letters and numbers, each character representing different geometric parameters or functional characteristics, such as the naming convention for the TNMG160404R-PV turning insert from Lizhou.

2025-05-26

What types of end mills are there?

Materials can be processed according to different types of end mills, categorized by the types of milling tools, including flat end mills, ball end mills, radius end mills, chamfer end mills, and end mills with chip breakers.

2025-05-23

PCD milling cutter is a polycrystalline diamond (PCD) milling cutter, which has a wide range of applications in the field of machining.

2025-05-08

End mill for machining aluminum materials

Many customers have told us that ordinary end mills frequently stick when machining aluminum, and the accumulation of chips affects the accuracy, so they always change the tools. LIZHOU editor suggests that coated end mills are not recommended for aluminum materials, because some coatings contain aluminum elements. Therefore, it is better to choose uncoated end mills when selecting end mills for machining aluminum materials.