Product

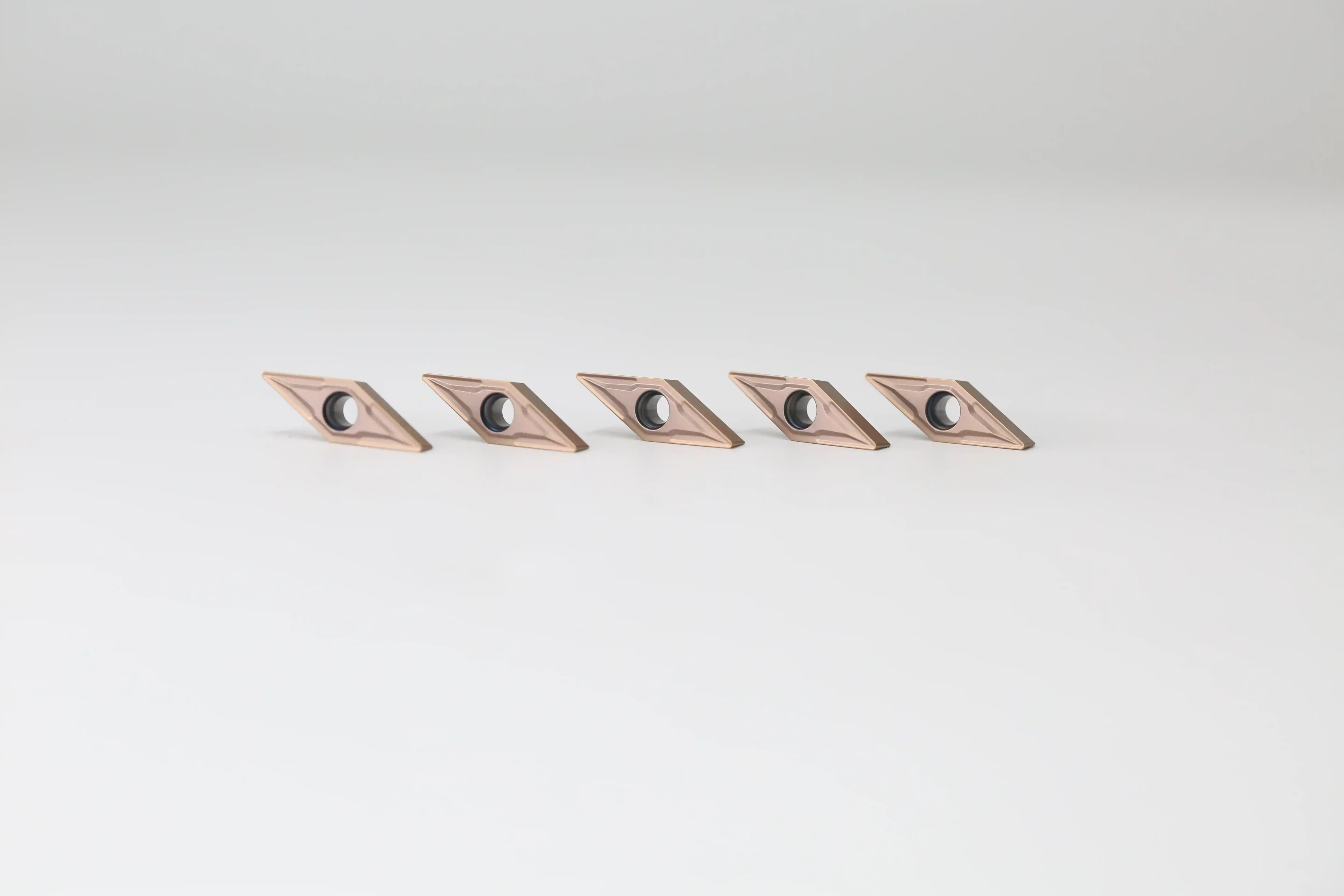

CCMT general turning inserts

China Lizhou Hard Alloy Source Factory

Product Name:Steel Turning Inserts

Coating : PVD

Brand number:LMP202

Classification :

Turning insert

keyword:

lizhou

CCMT060202, CCMT09T304, and CCMT120404 Carbide Turning Inserts: Precision, Versatility, and Durability

Introduction

In the field of precision machining, carbide inserts have become indispensable for delivering efficiency, accuracy, and superior surface finishes. Among the wide variety of geometries, CCMT inserts are some of the most widely used across industries due to their excellent balance between strength and sharpness, making them ideal for finishing, semi-finishing, and light roughing applications.

Our company, a professional carbide insert manufacturer, produces CCMT060202, CCMT09T304, and CCMT120404 turning inserts, designed for different turning needs while ensuring maximum tool life and reduced machining costs.

This article provides a comprehensive analysis of these CCMT inserts, covering their advantages, nomenclature meaning, parameters, features, application scenarios, precautions, and technological innovations.

Type | Basic Dimensions (mm) | Cutting Data | PVD | CVD | |||||

I.C | S | D | R | Cutting Depth (mm) | Feed ( mm/tooth ) | LMP202 | LKC202 | LPC202 | |

CCMT 060202 | 6.35 | 2.38 | 2.80 | 0.2 | 1.00-2.00 | 0.10-0.25 | ⚪ |

|

|

CCMT 060204 | 6.35 | 2.38 | 2.80 | 0.4 | 1.20-3.00 | 0.12-0.30 | ⚪ |

|

|

CCMT 060208 | 6.35 | 2.38 | 2.80 | 0.8 | 1.20-3.00 | 0.12-0.30 | ⚪ |

|

|

CCMT 09T304 | 9.525 | 3.97 | 4.40 | 0.4 | 1.00-3.00 | 0.07-0.25 | ⚪ |

|

|

CCMT 09T308 | 9.525 | 3.97 | 4.40 | 0.8 | 1.00-3.00 | 0.10-0.25 | ⚪ |

|

|

CCMT 120404 | 12.7 | 4.76 | 5.50 | 0.4 | 1.20-3.00 | 0.12-0.30 | ⚪ |

|

|

CCMT 120408 | 12.7 | 4.76 | 5.50 | 0.8 | 1.20-3.00 | 0.12-0.30 | ⚪ |

|

|

1. Advantages of CCMT Carbide Inserts

High Wear Resistance

Manufactured from fine-grain tungsten carbide substrates with advanced coatings, these inserts withstand high cutting speeds and abrasive materials.

Superior Surface Finish

CCMT inserts feature a 7° clearance angle, reducing friction and ensuring smooth surface quality.

Versatile Cutting Applications

From steel and stainless steel to non-ferrous metals, CCMT inserts offer excellent adaptability.

Economical Cutting Solution

Multi-edged inserts reduce tooling costs, as each insert can be indexed several times before replacement.

Stable Performance

Their precise geometry guarantees consistent chip control and minimizes vibration, even in high-precision CNC turning.

2. Decoding the CCMT Nomenclature

Each letter and number in CCMT060202, CCMT09T304, and CCMT120404 follows the ISO insert designation system.

CCMT

C = Shape: 80° rhombic diamond – a strong and versatile geometry.

C = Relief angle: 7° clearance for reduced cutting forces.

M = Tolerance class: Medium precision, suitable for general to precision turning.

T = Insert type: Single-sided insert with hole for screw clamping.

Numerical Codes

CCMT060202

06 = Cutting edge length (~6.35 mm).

02 = Insert thickness (~2.38 mm).

02 = Nose radius (0.2 mm) → Excellent for fine finishing.

CCMT09T304

09 = Cutting edge length (~9.52 mm).

T3 = Insert thickness (~3.97 mm).

04 = Nose radius (0.4 mm) → Ideal for finishing and semi-finishing.

CCMT120404

12 = Cutting edge length (~12.7 mm).

04 = Insert thickness (~4.76 mm).

04 = Nose radius (0.4 mm) → Stronger edge for medium cutting.

3. Performance Analysis

CCMT060202 – Ultra-Precision Insert

Strengths: Small nose radius, sharp edge.

Applications: Finishing on small workpieces, precision shafts, and medical parts.

Advantages: Produces mirror-like finishes with minimal cutting forces.

CCMT09T304 – Versatile Finishing Insert

Strengths: Medium size, balanced between edge strength and sharpness.

Applications: Automotive components, aerospace parts, and stainless steel finishing.

Advantages: Excellent chip control with stability at medium cutting parameters.

CCMT120404 – Heavy-Duty Finishing Insert

Strengths: Larger size, stronger edge, higher feed capacity.

Applications: General engineering, heavy-duty semi-finishing of steels and cast iron.

Advantages: Longer tool life, better resistance to tool breakage in tougher operations.

4. Application Scenarios

Automotive Industry

Engine shafts, brake discs, gear components.

High-volume finishing and semi-finishing.

Aerospace Industry

Stainless steels, titanium alloys, nickel-based alloys.

Contour turning and finishing of precision parts.

Medical Devices

Precision finishing of implants and surgical tools.

General Engineering & Manufacturing

Hydraulic components, rollers, and industrial parts.

Semi-finishing and precision turning of steel and non-ferrous materials.

5. Features of CCMT Inserts

Strong 80° Geometry → Excellent edge strength compared to sharper inserts.

Optimized Chipbreaker Design → Smooth chip evacuation for reduced downtime.

Multiple Nose Radii Options → From fine finishing (0.2 mm) to medium finishing (0.4 mm).

High Versatility → Suitable for CNC lathes and conventional turning machines.

Reduced Cutting Forces → Enhances stability in thin-walled and small parts machining.

6. Precautions for Use

Correct Clamping

Ensure proper screw tightening; misalignment can reduce tool life.

Optimized Parameters

CCMT060202 → Low feed (f = 0.05–0.15 mm/rev), shallow cuts.

CCMT09T304 → Moderate feed (f = 0.15–0.25 mm/rev), finishing to semi-finishing.

CCMT120404 → Higher feed (f = 0.25–0.35 mm/rev), semi-finishing of tougher materials.

Coolant Use

Use coolant for stainless steel and superalloys.

Dry cutting possible for cast iron.

Avoid Shock Loads

Carbide inserts are hard but brittle. Interrupted cuts must be approached with care.

Index Before Replacement

Rotate to a fresh cutting edge before the tool fails completely to avoid damaging workpieces.

7. Technological & Patent Innovations

Nano-Grain Carbide Substrates

Enhanced toughness while maintaining hardness.

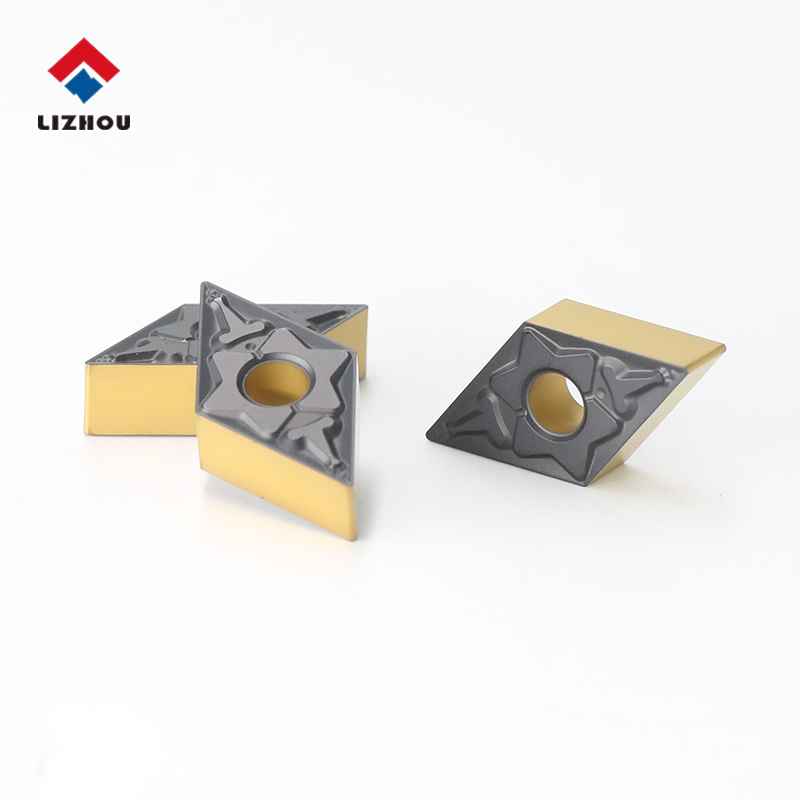

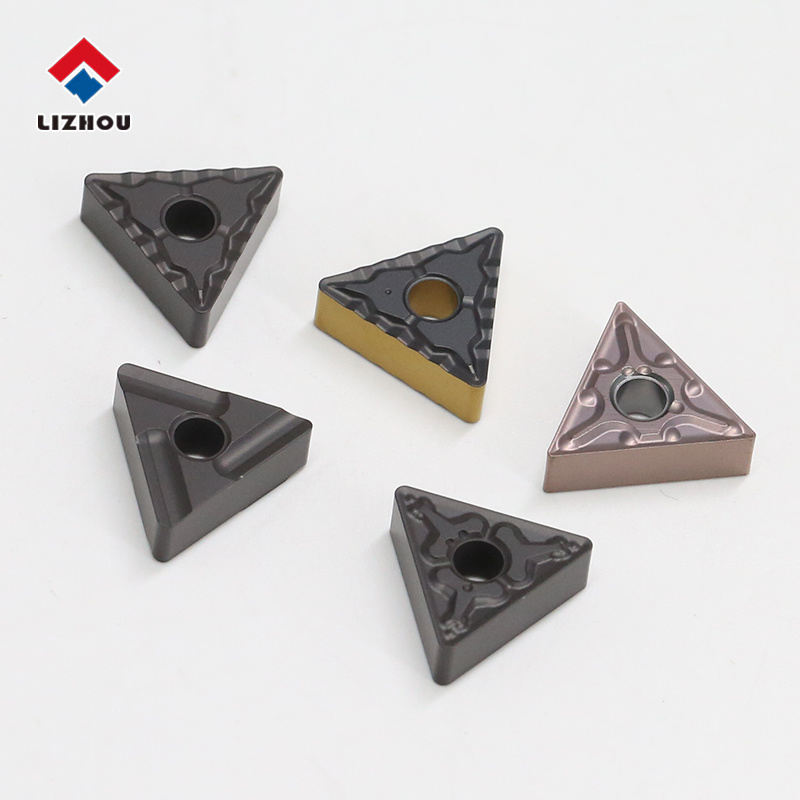

Advanced Coatings

CVD (TiCN + Al₂O₃): Long life in steels and cast irons.

PVD (TiAlN, AlCrN): Excellent for stainless steels and heat-resistant alloys.

Chipbreaker Engineering

Proprietary groove designs ensure smooth chip evacuation across feed ranges.

Precision Grinding

Tight ISO tolerances guarantee repeatability in automated production lines.

8. Why Choose Our CCMT Inserts?

Direct Manufacturer Supply: Competitive pricing, strict QC.

Full Size Range: From micro-finishing inserts to heavy-duty sizes.

Customized Solutions: Coating grades tailored for specific materials.

Global Reach: Used by clients in automotive, aerospace, and general engineering.

Innovation Driven: Continuous R&D investment in substrates and coatings.

Conclusion

The CCMT060202, CCMT09T304, and CCMT120404 carbide turning inserts offer manufacturers a reliable, cost-effective, and versatile solution for precision turning.

CCMT060202: Best for ultra-fine finishing.

CCMT09T304: Balanced insert for finishing and semi-finishing.

CCMT120404: Larger, stronger insert for medium-duty finishing.

By combining fine-grain carbide substrates, advanced coatings, optimized chipbreakers, and ISO precision, these inserts ensure excellent surface quality, longer tool life, and reduced machining costs.

For companies seeking to optimize performance and productivity, our CCMT carbide inserts are the ideal choice.

Previous page

Next page

Use equipment

CNC machining centre

CNC machine tools

Carved machine

Factory Board

Factory Board

Factory Board

Factory Board

Factory Board

Recommended products

FAQ

2025-05-29

The naming conventions for turning inserts generally follow international standards (such as ISO standards). The model number consists of a series of letters and numbers, each character representing different geometric parameters or functional characteristics, such as the naming convention for the TNMG160404R-PV turning insert from Lizhou.

2025-05-26

What types of end mills are there?

Materials can be processed according to different types of end mills, categorized by the types of milling tools, including flat end mills, ball end mills, radius end mills, chamfer end mills, and end mills with chip breakers.

2025-05-23

PCD milling cutter is a polycrystalline diamond (PCD) milling cutter, which has a wide range of applications in the field of machining.

2025-05-08

End mill for machining aluminum materials

Many customers have told us that ordinary end mills frequently stick when machining aluminum, and the accumulation of chips affects the accuracy, so they always change the tools. LIZHOU editor suggests that coated end mills are not recommended for aluminum materials, because some coatings contain aluminum elements. Therefore, it is better to choose uncoated end mills when selecting end mills for machining aluminum materials.