Product

SEKT face milling cutter

China Lizhou Hard Alloy Source Factory

Product Name: face milling cutter

Coating : PVD

Material:Tungsten steel

Classification :

Milling insert

keyword:

lizhou

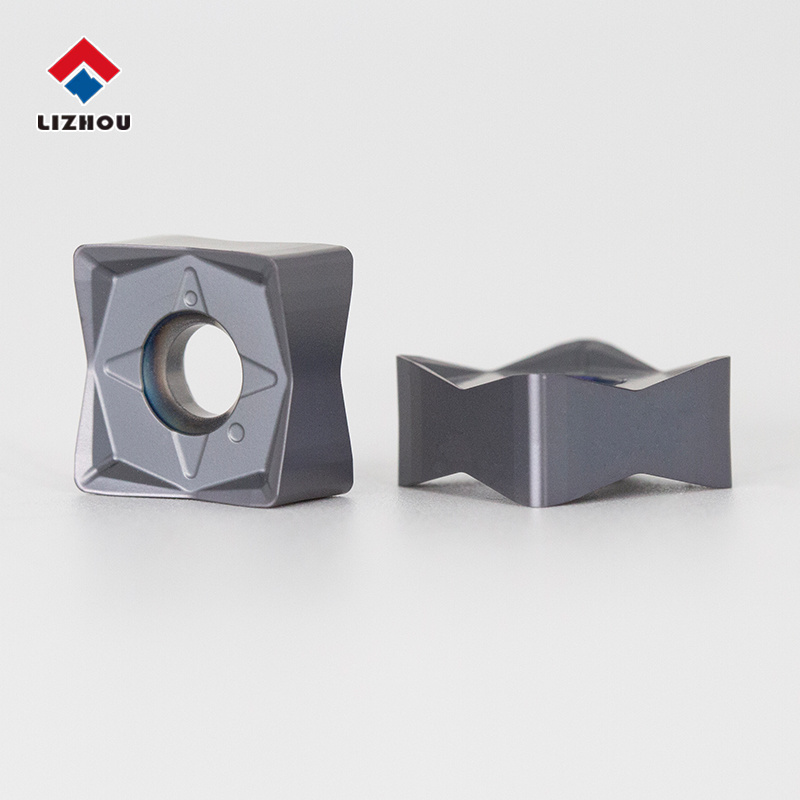

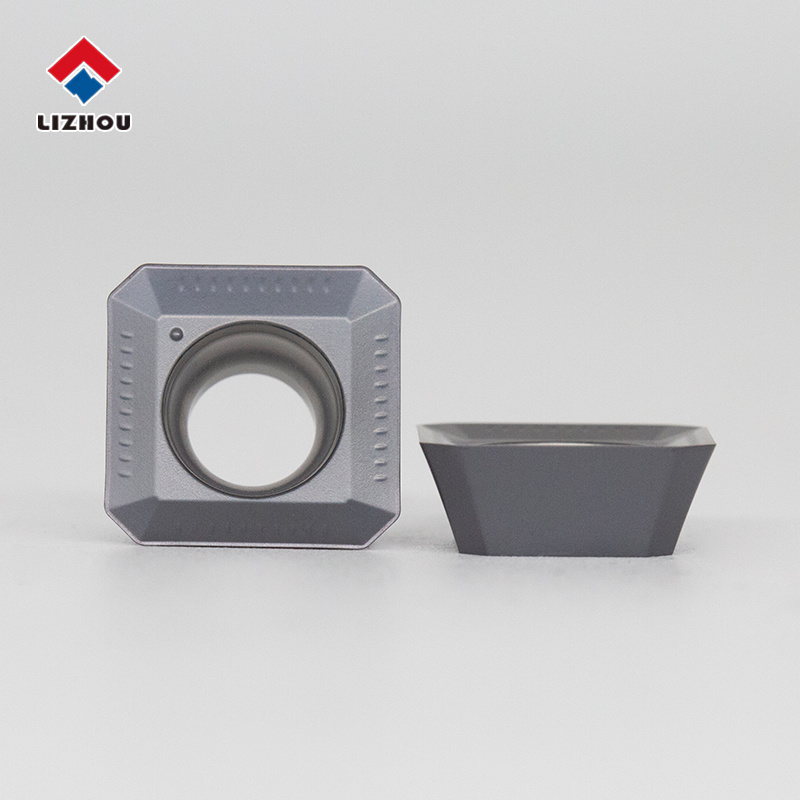

SEKT1204AFTN Carbide Milling Insert – Precision, Performance, and Productivity

Introduction

In modern machining, the choice of cutting inserts directly determines efficiency, tool life, and product quality. Among the wide range of inserts used for face milling, shoulder milling, and contouring, the SEKT1204AFTN carbide insert stands out as a high-performance solution designed for precision machining.

As a professional carbide manufacturer, we develop inserts that combine durability, versatility, and advanced technology. The SEKT1204AFTN insert has been engineered to meet the requirements of industries such as aerospace, automotive, mold-making, energy, and heavy equipment manufacturing.

This article provides a complete overview of the advantages, technical specifications, geometry explanation, performance analysis, applications, precautions, and innovations of the SEKT1204AFTN insert.

1. Understanding the Code: SEKT1204AFTN

Carbide insert designations follow ISO standards. Every letter and number in SEKT1204AFTN provides insight into the insert’s shape, relief angle, tolerance, and geometry.

S – Insert shape: Square, offering four cutting edges per insert. This maximizes cost efficiency.

E – Relief angle: 20°, providing clearance behind the cutting edge, suitable for positive rake milling cutters.

K – Tolerance: Indicates a ground insert with high precision, ensuring consistency in CNC machining.

T – Hole/Chipbreaker style: Typically refers to the clamping system, designed for stable fixation.

12 – Size code: Refers to the 12 mm inscribed circle (IC).

04 – Thickness: 4 mm, balancing strength with sharpness.

AFTN – Special geometry code:

A: Geometry designed for aluminum and non-ferrous machining.

F: Fine cutting edge, minimizing cutting resistance.

TN: Indicates a high-polished surface and sharp rake angle for excellent chip evacuation.

From this code, we understand that the SEKT1204AFTN is a square, ground, sharp-edged, polished insert designed for aluminum and non-ferrous machining with excellent precision.

2. Product Advantages

2.1 High Precision Machining

The ground cutting edge and precise tolerance class ensure consistent dimensional accuracy. This makes SEKT1204AFTN suitable for CNC high-speed milling.

2.2 Excellent Surface Finish

The sharp edge with polished rake face reduces friction and prevents built-up edge, delivering a mirror-like surface finish on aluminum and copper alloys.

2.3 Superior Chip Evacuation

Thanks to its optimized rake angle and polished chipbreaker design, chips are removed smoothly, avoiding sticking or re-cutting that could damage the workpiece.

2.4 Long Tool Life

Manufactured with premium tungsten carbide substrate and nano-coatings, this insert provides excellent wear resistance, heat resistance, and toughness, even under continuous cutting.

2.5 Cost-Effectiveness

Square inserts with four usable edges reduce tooling costs, making them highly economical for mass production environments.

3. Application Scenarios

The SEKT1204AFTN insert is widely used in industries that require high-speed machining of non-ferrous materials.

Aerospace – Machining aluminum alloys for fuselage and wing structures.

Automotive – Cylinder heads, transmission cases, and lightweight alloy components.

Mold-making – Precision finishing of aluminum molds.

Electronics – High-speed milling of copper alloys and heat sinks.

General engineering – Any high-speed milling of aluminum, magnesium, or plastics reinforced with fibers.

4. Technical Performance Analysis

4.1 Substrate and Coating

Substrate: Ultra-fine carbide grains improve toughness and prevent edge chipping.

Coating: Depending on customer requirement, TiN, TiAlN, or DLC coatings may be applied for improved wear resistance and smoother chip flow.

4.2 Cutting Parameters

| Material | Cutting Speed (Vc) | Feed per Tooth (fz) | Depth of Cut (ap) |

|---|---|---|---|

| Aluminum Alloys | 500–2000 m/min | 0.05–0.25 mm | Up to 4 mm |

| Copper Alloys | 250–800 m/min | 0.05–0.20 mm | Up to 3 mm |

| Plastics/Composites | 200–500 m/min | 0.05–0.15 mm | Up to 2 mm |

5. Features & Benefits at a Glance

Square design – 4 cutting edges per insert.

Polished rake face – Prevents material adhesion.

Optimized for aluminum & non-ferrous metals.

Excellent surface finish with minimum rework.

Stable clamping system ensures safety in high-speed machining.

Cost-saving – longer tool life and multiple edges.

6. Precautions in Use

Avoid improper clamping – Ensure correct torque for screws to prevent insert cracking.

Use appropriate coolant – For aluminum, apply abundant coolant or MQL to prevent adhesion.

Rotate edges systematically – Use all four edges evenly to extend insert life.

Check for built-up edge – Replace inserts before severe adhesion damages the workpiece.

Match cutter body properly – Use SEKT-compatible face mills or end mills for best stability.

7. Technological & Innovative Aspects

Mirror-polished rake face – A patented polishing process minimizes friction and prevents sticking.

Ultra-fine carbide substrate – Improves resistance to micro-cracks at high cutting speeds.

Coating technology – DLC or TiB₂ coatings for extreme aluminum machining without welding.

Precision grinding process – Ensures tight tolerances for CNC finishing.

Sustainable manufacturing – Energy-efficient carbide sintering process.

8. Why Choose Us as Your Carbide Insert Supplier?

Factory-direct supply – Lower costs compared to trading companies.

Full product range – SEKT, APKT, APMT, RDMW, RPMW, BLMP, HNMU, and custom inserts.

Customization service – OEM/ODM options available for specific industry needs.

Strict QC system – 100% inspection of every batch.

Global export experience – Supplying to aerospace, automotive, mold-making, and heavy machinery markets worldwide.

onclusion

The SEKT1204AFTN carbide milling insert is an advanced cutting solution designed for aluminum and non-ferrous machining at high speeds. With its square shape, four cutting edges, polished rake face, and precision-ground geometry, it delivers superior surface finishes, efficient chip control, and excellent tool life.

As a professional carbide manufacturer, we not only provide high-quality inserts but also support customers with customized solutions, innovative technologies, and reliable global supply.

Frequently Asked Questions

Q1: What is the minimum order quantity (MOQ)? Do you support mixed batches?

The regular MOQ is 10 boxes (10 pieces per box). Some suppliers support purchasing mixed models, which requires prior consultation.

Q2: How long is the delivery time? Is there any stock?

The standard delivery time is 15-30 days (depending on the coating customization requirements). Conventional models are usually in stock, and special coatings need to be pre-ordered.

Q3: Do you provide free samples? Who bears the shipping cost?

The supplier provides one box of samples, and the shipping cost is usually borne by the buyer

Previous page

Next page

Use equipment

CNC machining centre

CNC machine tools

Carved machine

Factory Board

Factory Board

Factory Board

Factory Board

Factory Board

Recommended products

FAQ

2025-05-29

The naming conventions for turning inserts generally follow international standards (such as ISO standards). The model number consists of a series of letters and numbers, each character representing different geometric parameters or functional characteristics, such as the naming convention for the TNMG160404R-PV turning insert from Lizhou.

2025-05-26

What types of end mills are there?

Materials can be processed according to different types of end mills, categorized by the types of milling tools, including flat end mills, ball end mills, radius end mills, chamfer end mills, and end mills with chip breakers.

2025-05-23

PCD milling cutter is a polycrystalline diamond (PCD) milling cutter, which has a wide range of applications in the field of machining.

2025-05-08

End mill for machining aluminum materials

Many customers have told us that ordinary end mills frequently stick when machining aluminum, and the accumulation of chips affects the accuracy, so they always change the tools. LIZHOU editor suggests that coated end mills are not recommended for aluminum materials, because some coatings contain aluminum elements. Therefore, it is better to choose uncoated end mills when selecting end mills for machining aluminum materials.