Product

SEKN gantry milling cutter

China Lizhou Hard Alloy Source Factory

Classification :

Milling insert

keyword:

lizhou

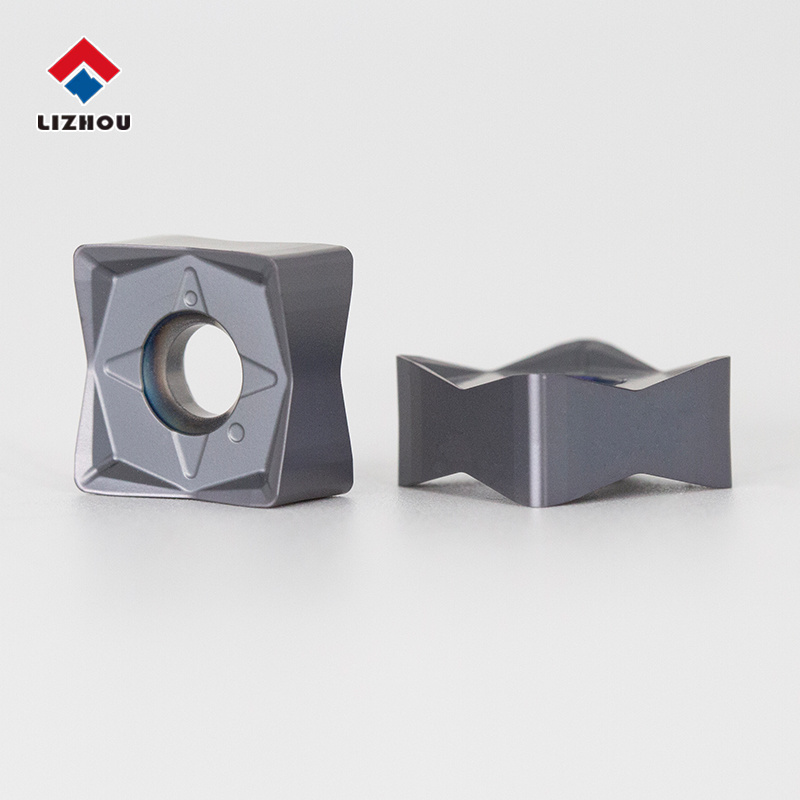

SEKN1203AFN Carbide Milling Insert – Precision, Durability, and Efficiency for Modern Machining

Introduction

In today’s fast-evolving manufacturing industry, efficiency and precision are the driving forces behind productivity. Cutting tools, particularly carbide inserts, play a critical role in machining performance. Carbide inserts not only reduce machining costs but also enhance surface finish, tool life, and cutting stability.

Among these inserts, the SEKN1203AFN carbide milling insert has gained recognition for its high wear resistance, versatile applications, and optimized geometry. As a professional carbide manufacturer, our company has developed this insert to meet the needs of high-performance milling operations in automotive, aerospace, mold-making, and heavy engineering industries.

This article provides a comprehensive technical and practical guide to the SEKN1203AFN insert, including code breakdown, performance advantages, applications, key features, precautions, and our technological innovations.

Blade Length | Cutting Depth (mm) | Feed Rate (mm/tooth ) | Material to be Machined | K | P | H | M | S | ||||||

12- | 1.5-5.5 | 0.10-0.25 | Cast Iron | Steel | Hardened Steel | Stainless Steel | Titanium Nickel Alloy | |||||||

15- | 1.5-7.5 | 0.10-0.25 | ||||||||||||

Type | Basic Dimensions (mm) | CVD | PVD | |||||||||||

I.C | S | r | d | LKC206 | LKP206 | LPP106 | LPP206 | LPP306 | LHP206 | LMP106 | LMP206 | LSP206 | ||

SEKN1203AFN | 12.7 | 3.18 | 1.2 | 2.0 |

|

| ◎ |

| ◎ |

|

| ◎ |

| |

SEKN1203AFTN |

|

| ◎ |

| ◎ |

|

| ◎ |

| |||||

SEKN1504AFN | 15.875 | 4.76 | 1.6 | 2.0 |

|

|

|

| ◎ |

|

| ◎ |

| |

SEKN1504AFTN |

|

|

|

| ◎ |

|

| ◎ |

| |||||

1. Code Breakdown: Understanding SEKN1203AFN

The designation SEKN1203AFN follows ISO insert nomenclature, where each character provides specific information about shape, geometry, and application.

S – Insert Shape: Square insert, offering four sides with two cutting edges each, giving a total of 8 usable cutting edges. Cost-effective for high-volume production.

E – Relief Angle: 20° relief angle, which reduces cutting resistance and improves sharpness for smooth milling.

K – Tolerance: General tolerance, balancing dimensional accuracy with affordability.

N – Hole/Clamping: Neutral clamping hole, ensuring secure mounting in standard tool holders.

12 – Size: Insert with 12 mm inscribed circle (IC), suitable for medium-to-large milling cutters.

03 – Thickness: Approximately 3.97 mm (≈4 mm), designed for stability during medium-depth cuts.

A – Edge Preparation: Standard chamfer or honing to reinforce cutting edge strength.

F – Chipbreaker Type: Finishing geometry, optimized for fine surface finish and controlled chip evacuation.

N – Insert Style: General-purpose milling insert, adaptable to multiple materials and cutting conditions.

This systematic coding helps engineers and purchasing teams quickly understand the geometry and suitability of the insert.

2. Advantages of SEKN1203AFN Carbide Insert

The SEKN1203AFN offers multiple advantages due to its optimized design and carbide properties:

Multiple Cutting Edges

Eight cutting edges per insert maximize cost efficiency.

Reduces tool change frequency and lowers cost-per-part.

High Hardness and Wear Resistance

Manufactured from premium tungsten carbide substrates.

Withstands high cutting speeds and abrasive wear.

Excellent Thermal Stability

Maintains edge strength under high machining temperatures.

Performs well in both wet and dry milling operations.

Optimized Finishing Geometry

"F" chipbreaker design ensures precise chip control.

Produces superior surface quality with minimal secondary finishing required.

Versatility

Suitable for milling steel, cast iron, stainless steel, and alloys.

Adaptable to finishing and semi-finishing applications.

3. Performance Analysis

The SEKN1203AFN insert is specifically engineered for stability and precision in milling.

Cutting Efficiency: Square shape distributes cutting loads evenly, reducing vibration and improving tool life.

Chip Control: “F” chipbreaker promotes smooth chip flow, preventing chip jamming and heat accumulation.

Surface Finish: Achieves excellent surface roughness, ideal for mold and die industries.

Tool Life: Advanced coatings (TiAlN, AlTiN, or CVD multilayers) extend tool longevity by reducing crater and flank wear.

Dimensional Accuracy: Balanced edge preparation ensures repeatable performance in high-volume machining.

4. Application Scenarios

The SEKN1203AFN carbide insert is widely used in different sectors:

Automotive Industry

Cylinder blocks, gear housings, transmission components.

Aerospace

Precision machining of heat-resistant alloys and lightweight metals.

Mold & Die

Fine milling of mold cavities requiring smooth finishes.

General Engineering

Suitable for structural steel, cast iron, and stainless-steel parts.

Heavy Equipment Manufacturing

Large part finishing where tool stability is critical.

5. Key Features and Benefits

Square Shape (S) → Provides 8 cutting edges for cost efficiency.

20° Relief Angle (E) → Enhances cutting sharpness and reduces tool pressure.

Neutral Clamping (N) → Ensures stable, secure mounting for reliable performance.

Finishing Geometry (F) → Optimized for surface quality and chip evacuation.

Versatility → Works on multiple materials under various cutting conditions.

6. Precautions and Best Practices

To achieve optimal performance with SEKN1203AFN inserts, machinists should follow these guidelines:

Cutting Parameters

Use recommended cutting speeds and feeds based on material type.

Higher speeds for steel, moderate for cast iron, lower for stainless steel to prevent work hardening.

Secure Clamping

Ensure the insert is cleanly seated in the tool pocket before clamping.

Coolant Use

Dry milling is possible for cast iron and steel.

Cutting fluids recommended for stainless steel and alloys to reduce heat.

Insert Rotation

Regularly index the insert to use all available cutting edges.

Storage

Store inserts in dry, protected containers to preserve edge sharpness.

7. Technological Innovations

Our SEKN1203AFN carbide inserts incorporate advanced technologies:

High-Density Sintering – Improves hardness and fracture toughness.

Nano Coatings – Extends wear resistance under high-temperature operations.

Edge Honing Technology – Minimizes micro-chipping and increases edge durability.

Patented Chipbreaker Design – Ensures optimized chip evacuation and lower cutting resistance.

OEM/ODM Solutions – Custom geometries and coatings available based on customer demand.

8. Why Choose Us as Your Carbide Manufacturer

As a professional carbide manufacturer, we offer more than just products:

Factory-Direct Supply → Ensuring competitive pricing and stable stock.

Quality Assurance → Each batch tested for hardness (HRA), toughness, and coating adhesion.

Global Reach → Serving customers in Asia, South America, Africa, and Europe.

Engineering Support → Helping customers select inserts and optimize cutting parameters.

Customization → OEM/ODM solutions tailored to different industries and machining needs.

Conclusion

The SEKN1203AFN carbide milling insert is a versatile, cost-effective, and high-performance cutting solution. With 8 cutting edges, optimized chipbreaker geometry, advanced coatings, and stable clamping, it delivers superior tool life and surface quality across a wide range of applications.

Whether in automotive, aerospace, mold-making, or heavy engineering, the SEKN1203AFN ensures consistent results, reduced machining costs, and improved productivity.

As a trusted hard alloy manufacturer, we are dedicated to providing inserts like the SEKN1203AFN that combine cutting-edge technology, strict quality control, and industry-specific expertise to help global manufacturers achieve higher efficiency and profitability.

Previous page

Next page

Use equipment

CNC machining centre

CNC machine tools

Carved machine

Factory Board

Factory Board

Factory Board

Factory Board

Factory Board

Recommended products

FAQ

2025-05-29

The naming conventions for turning inserts generally follow international standards (such as ISO standards). The model number consists of a series of letters and numbers, each character representing different geometric parameters or functional characteristics, such as the naming convention for the TNMG160404R-PV turning insert from Lizhou.

2025-05-26

What types of end mills are there?

Materials can be processed according to different types of end mills, categorized by the types of milling tools, including flat end mills, ball end mills, radius end mills, chamfer end mills, and end mills with chip breakers.

2025-05-23

PCD milling cutter is a polycrystalline diamond (PCD) milling cutter, which has a wide range of applications in the field of machining.

2025-05-08

End mill for machining aluminum materials

Many customers have told us that ordinary end mills frequently stick when machining aluminum, and the accumulation of chips affects the accuracy, so they always change the tools. LIZHOU editor suggests that coated end mills are not recommended for aluminum materials, because some coatings contain aluminum elements. Therefore, it is better to choose uncoated end mills when selecting end mills for machining aluminum materials.