Product

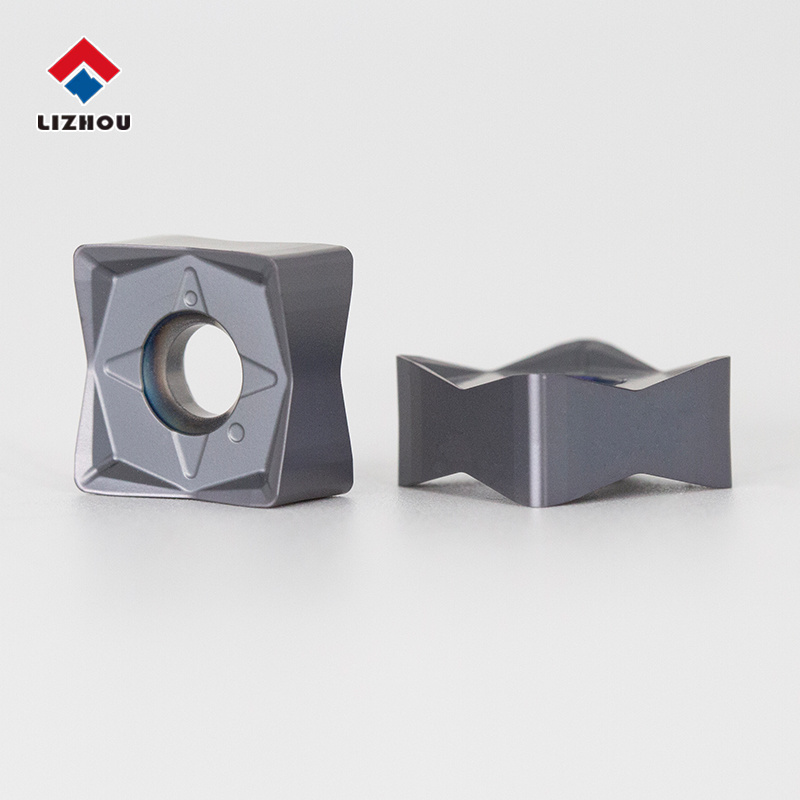

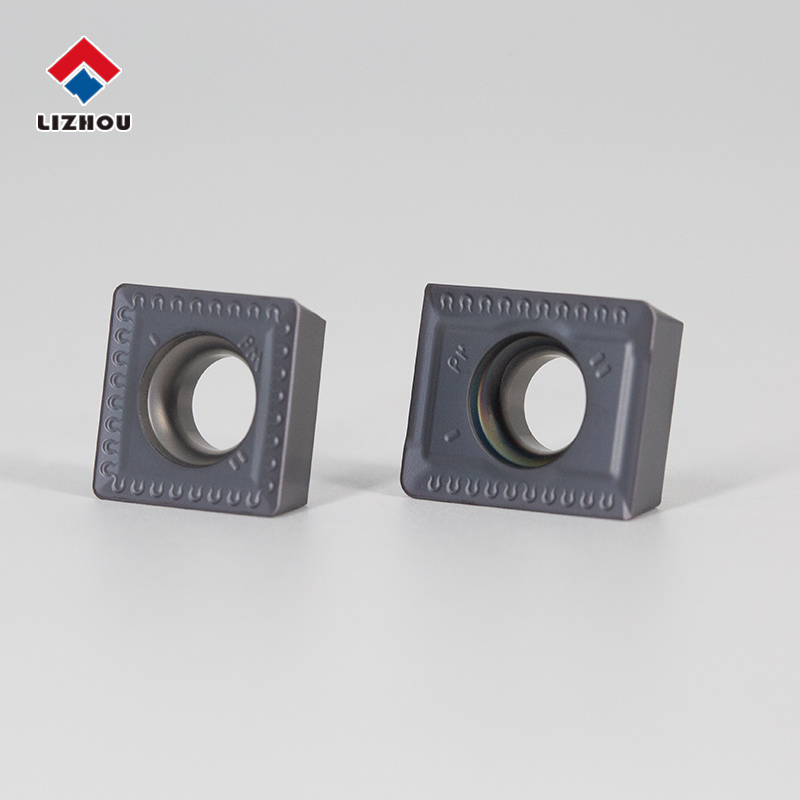

SEKR face milling cutter

China Lizhou Hard Alloy Source Factory

Product Name: face milling cutter

Coating : PVD

Material:Tungsten steel

Classification :

Milling insert

keyword:

lizhou

SEKR1203AFTN Carbide Milling Insert – High-Performance Solution for Precision Machining

Introduction

In the field of modern machining, the demand for tools that can balance productivity, cost-efficiency, and durability continues to grow. Carbide inserts are the backbone of milling operations in industries ranging from automotive and aerospace to mold-making and general engineering. Among the wide variety of milling inserts, the SEKR1203AFTN stands out for its precision, reliability, and superior performance.

As a professional carbide manufacturer, our company has developed the SEKR1203AFTN insert to meet the requirements of demanding cutting operations. It is designed with advanced carbide substrates, innovative coatings, and optimized geometries to ensure high efficiency and consistent results in various machining environments.

This article provides a comprehensive overview of the SEKR1203AFTN carbide insert, including its code breakdown, performance analysis, application scenarios, features, precautions, and technical innovations, helping buyers and engineers make an informed choice.

Blade length | Cutting depth (mm) | Feed rate (mm/tooth ) | Workpiece material | K | P | H | M | S | |||||||

12- | 1.5-5.5 | 0.10-0.40 | Cast iron | Steel | Hardened steel | Stainless steel | Titanium nickel alloy | ||||||||

Type | Basic dimensions (mm) | CVD | PVD | ||||||||||||

I.C | S | r | d | LKC206 | LKP206 | LPP106 | LPP206 | LPP306 | LHP206 | LMP106 | LMP206 | LSP206 | |||

SEKR1203AFTN | 12.7 | 3.18 | 1.6 | 2.0 |

|

| ◎ | ◎ |

|

|

| ◎ |

| ||

1. Breaking Down the Code: SEKR1203AFTN

Carbide insert nomenclature follows international standards (ISO/ANSI), where each letter and number communicates a specific design feature. Let us decode SEKR1203AFTN step by step:

S – Insert Shape: Square insert, providing four cutting edges per side and eight edges in total for cost efficiency.

E – Relief Angle: 20° clearance angle, improving cutting edge sharpness and reducing cutting forces.

K – Tolerance Class: Medium precision insert, suitable for both general-purpose and precision milling.

R – Hole/Clamping System: Round hole, compatible with screw clamping systems, ensuring rigidity and stability.

12 – Size: 12 mm inscribed circle (IC), a common standard size for milling applications.

03 – Thickness: 3.97 mm (≈ 4 mm), making it versatile for both light and medium-duty milling.

A – Edge Preparation: Standard chamfer or honing for reinforced cutting edge strength.

F – Chipbreaker Design: Finishing geometry, optimized for fine surface quality and low cutting resistance.

TN – Application Style: Designed for milling operations, providing robust cutting edges and stable chip evacuation.

This classification ensures machinists, engineers, and procurement specialists can clearly understand the geometry, clamping system, and intended usage of the insert.

2. Advantages of Carbide Inserts (SEKR1203AFTN)

The SEKR1203AFTN insert is manufactured using premium tungsten carbide substrates with advanced CVD/PVD coatings, giving it several unique advantages:

High Hardness and Wear Resistance

Can withstand cutting speeds significantly higher than high-speed steel (HSS).

Excellent resistance against abrasive wear during high-volume production.

Thermal Stability

Maintains strength at high machining temperatures.

Suitable for dry and high-speed milling applications.

Edge Toughness

Optimized geometry reduces chipping risks.

Balanced toughness ensures stable performance in interrupted cuts.

Long Tool Life

Advanced coatings (TiAlN, AlTiN, or CVD multilayer) minimize crater wear and flank wear.

Extended insert life reduces downtime and tool change frequency.

Cost Efficiency

Multi-edge design provides up to 8 usable cutting edges per insert, lowering cost-per-part.

3. Performance Analysis of SEKR1203AFTN

The SEKR1203AFTN is a finishing-grade insert, but its versatility allows both finishing and semi-finishing in different materials.

Cutting Efficiency: The sharp edge geometry and 20° relief angle reduce cutting resistance, enabling high-speed operations.

Chip Control: The “F” chipbreaker design promotes smooth chip evacuation, avoiding chip re-cutting and improving surface quality.

Surface Finish: Provides fine surface finishes, ideal for precision components and mold applications.

Tool Life: Coatings and edge preparation significantly extend usable life, especially under stable cutting conditions.

Stability: Secure screw clamping ensures vibration resistance and consistent performance.

4. Application Scenarios

The SEKR1203AFTN carbide insert is widely used in multiple industries and machining operations:

Automotive Industry

Finishing of engine blocks, transmission housings, and brake components.

Aerospace Sector

Milling lightweight alloys and heat-resistant superalloys for turbine and structural parts.

Mold and Die Industry

Fine milling of mold cavities and surfaces requiring excellent dimensional accuracy.

General Engineering

Precision machining of steel, stainless steel, and cast iron parts.

Energy and Heavy Equipment

Precision milling in wind power hubs, compressors, and heavy machinery components.

5. Key Features and Benefits

Square Shape (S) → 8 cutting edges for maximum cost efficiency.

20° Relief Angle (E) → Sharp edges for smooth cutting and low resistance.

Finishing Geometry (F) → Superior surface quality.

Optimized Chip Control → Prevents chip clogging and heat buildup.

Versatility → Effective on steels, cast irons, stainless steels, and alloys.

Stable Clamping (R) → Secure screw system ensures rigidity in high-speed cutting.

6. Precautions and Best Practices

To achieve optimal results with SEKR1203AFTN, machinists should follow these guidelines:

Correct Cutting Parameters

Adjust cutting speed and feed per tooth according to material type.

For finishing, use higher spindle speeds with lower feed rates.

Insert Clamping

Ensure clean, rigid clamping to avoid insert movement or vibration.

Coolant Use

For steels and cast irons, dry cutting is possible.

For stainless steels and heat-resistant alloys, cutting fluid is recommended.

Inspection and Replacement

Replace inserts at early wear stages to prevent tool failure.

Proper Storage

Store in anti-moisture, anti-corrosion containers to preserve coatings and cutting edges.

7. Technological Innovations and Patents

Our carbide manufacturing expertise integrates advanced technologies into SEKR1203AFTN inserts:

Nano-Coating Technology – Extends tool life with superior heat resistance.

High-Pressure Sintering – Improves carbide substrate density and strength.

Edge Preparation Innovations – Reduces micro-chipping and enhances cutting consistency.

Patented Chipbreaker Designs – Custom geometries available for specialized customer needs.

OEM/ODM Solutions – Tailored geometries, coatings, and branding available for global partners.

8. Why Choose Us as Your Carbide Supplier

As a hard alloy manufacturer, we offer complete solutions, not just products:

Direct Factory Supply → Ensuring competitive pricing and stable availability.

Strict Quality Control → Each batch undergoes hardness, toughness, and coating performance tests.

Global Reach → Serving clients across Asia, South America, Africa, Europe, and the Middle East.

Engineering Support → Helping clients optimize machining parameters for better performance.

OEM/ODM Services → Providing customization for branding and application-specific needs.

Conclusion

The SEKR1203AFTN carbide milling insert is a high-performance, finishing-oriented square insert that offers outstanding wear resistance, reliable chip control, and excellent surface quality. Its 8 usable cutting edges, advanced carbide substrate, and precision geometry make it one of the most cost-effective solutions in modern machining.

Designed for precision applications in automotive, aerospace, mold-making, and engineering industries, this insert ensures long tool life, superior surface finishes, and stable cutting performance.

As a trusted carbide manufacturer, we are committed to delivering products like SEKR1203AFTN that not only meet but exceed industry expectations, supporting global manufacturers in achieving higher productivity and profitability.

Previous page

Next page

Use equipment

CNC machining centre

CNC machine tools

Carved machine

Factory Board

Factory Board

Factory Board

Factory Board

Factory Board

Recommended products

FAQ

2025-05-29

The naming conventions for turning inserts generally follow international standards (such as ISO standards). The model number consists of a series of letters and numbers, each character representing different geometric parameters or functional characteristics, such as the naming convention for the TNMG160404R-PV turning insert from Lizhou.

2025-05-26

What types of end mills are there?

Materials can be processed according to different types of end mills, categorized by the types of milling tools, including flat end mills, ball end mills, radius end mills, chamfer end mills, and end mills with chip breakers.

2025-05-23

PCD milling cutter is a polycrystalline diamond (PCD) milling cutter, which has a wide range of applications in the field of machining.

2025-05-08

End mill for machining aluminum materials

Many customers have told us that ordinary end mills frequently stick when machining aluminum, and the accumulation of chips affects the accuracy, so they always change the tools. LIZHOU editor suggests that coated end mills are not recommended for aluminum materials, because some coatings contain aluminum elements. Therefore, it is better to choose uncoated end mills when selecting end mills for machining aluminum materials.