Product

FAQ

Tungsten carbide bar

China Lizhou Hard Alloy Source Factory

Grade:LBC15

Application:Soft wood

Classification :

Cemented Carbide Strip

keyword:

lizhou

Hard alloy bars are also rectangular tungsten carbide bars, also known as hard alloy flat bars. Their production method is the same as that of hard alloy round bars.

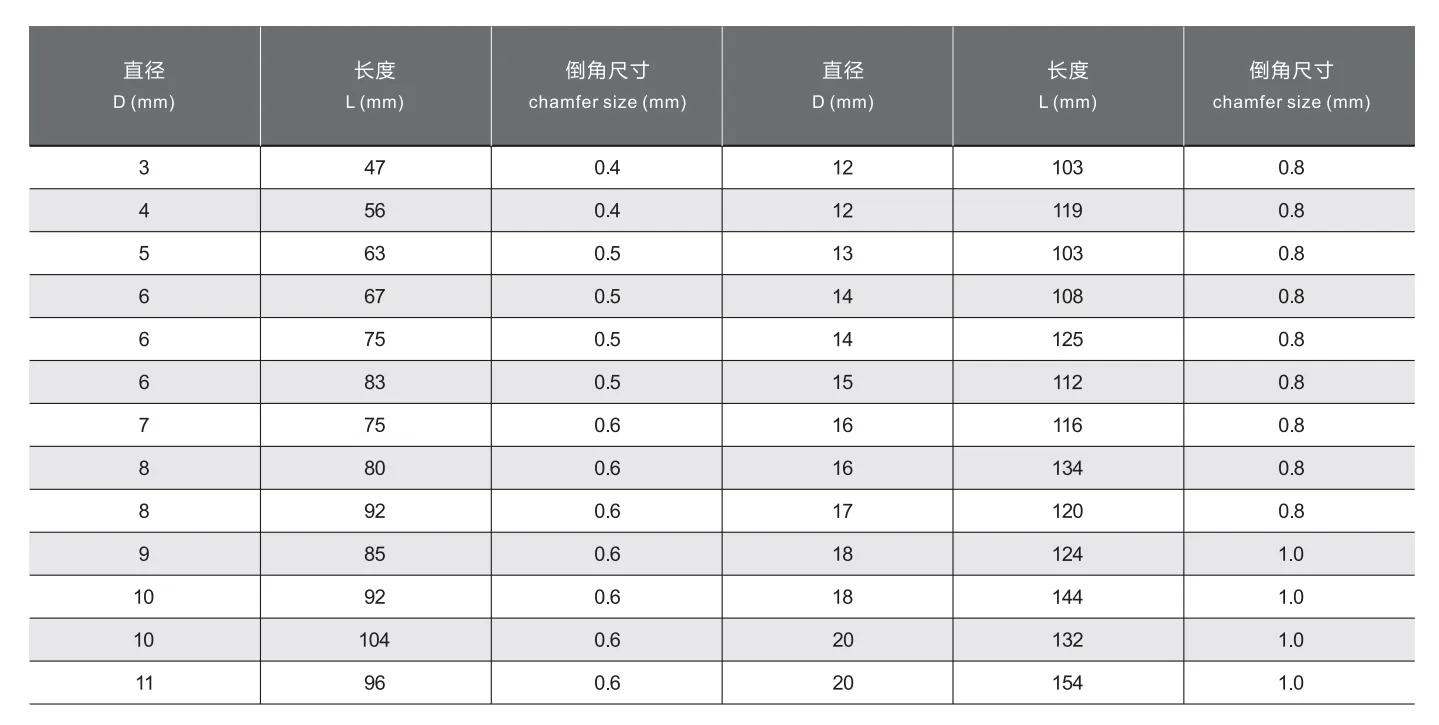

I. Hard alloy bar product parameters:

II. Product data parameters

Grade: LBC15

Cobalt content: 10%

Grain size: 0.8μm

Density: 14.4g/cm³

Hardness: 91.5HRA

Bending strength: 4100N/m㎡

Hard alloy bar production process:

Powder (mainly WC and Co powder mixed according to the formula ratio) mixing, ball milling, spray tower drying, extrusion, drying, sintering, (cutting or grinding if necessary), final inspection, packaging, delivery, intermediate inspection after each process to ensure that only qualified products can enter the next production process.

Cutting applications: Cork

Core advantages:

Hard alloy bars (tungsten steel bars) use ultra-fine grain tungsten carbide and cobalt-based formulas, with a hardness of up to 91.5HRA, and can be used in high-wear scenarios such as cutting metal and crushing ore

High-temperature oxidation resistance: The structure remains stable at 1200℃

Precision forming: Size tolerance is accurate to ±0.02mm, supporting customized cutting and surface treatment, adapting to various industrial needs

Why choose our Lizhou hard alloy bars:

1. Strict quality control throughout the process: From raw material sintering to precision grinding, 100% non-destructive testing ensures no pores and cracks.

2. Support customization: OEM customized size, special-shaped cross-section, gradient structure and other special needs, fast response and delivery.

3. Global verification: Products have been exported to more than 20 countries and served more than 5000 mechanical manufacturing and energy mining companies.

Use equipment

CNC machining centre

CNC machine tools

Carved machine

Factory Board

Factory Board

Factory Board

Factory Board

Factory Board

Recommended products

FAQ

2025-12-12

Lizhou Indexable U-Drill Series | High-Speed Drilling Solution for Large-Hole U-Drills

The Lizhou U-drill series is suitable for large-hole drilling in a variety of materials, including steel, stainless steel, alloy steel, and titanium alloys. It offers two structural types: square U-drills and peach-shaped U-drills. These drills combine rigidity, centering accuracy, and chip-removal efficiency, enabling multi-process machining that includes drilling, boring, and chamfering. Featuring high-quality carbide inserts and a stable tool body design, this series ensures more efficient batch drilling at lower costs.

2025-12-12

Lizhou Carbide Turning Inserts Series | Cemented Carbide CNC Turning Solutions

The Lizhou carbide turning blade series specializes in CNC turning applications using cemented carbide, covering common machining operations such as external cylindrical turning, end-face turning, roughing, and finishing. We offer diamond-shaped blades, square blades, triangular blades, peach-shaped blades, and peel-off blades, each tailored with specific grades and flute geometries for materials including cast iron, steel, stainless steel, high-hardness steel, and copper and aluminum. These blades help workshops enhance tool life and improve machining stability.

2025-12-12

Lizhou Threaded Blade Series | High-Precision, Stable Thread-Machining Solution

The Lizhou thread cutting blades are made from high-quality cemented carbide materials, combined with advanced coatings and precise tooth profile grinding, enabling them to meet the machining requirements of various thread standards. Whether working with steel, stainless steel, or high-temperature alloys, these blades maintain excellent wear resistance and cutting stability, making them ideal for mass production and thread machining applications that demand high consistency.

2025-12-12

Lizhou Solid Carbide End Mill Series | GX GG BS TS AL Milling Solutions

The Lizhou end-mill series covers a wide range of materials, including steel, stainless steel, quenched and tempered steel, aluminum alloys, and titanium alloys, and corresponds to five major carbide end-mill lines: GX, GG, BS, TS, and AL. Available in flat-end, round-nose, ball-nose, and multi-flute configurations, these end mills are suitable for roughing, finishing, and high-speed machining. Featuring an ultra-fine-grain matrix and comprehensive quality control throughout the entire manufacturing process, these tools deliver more stable tool life and smoother machining performance.