Product

FAQ

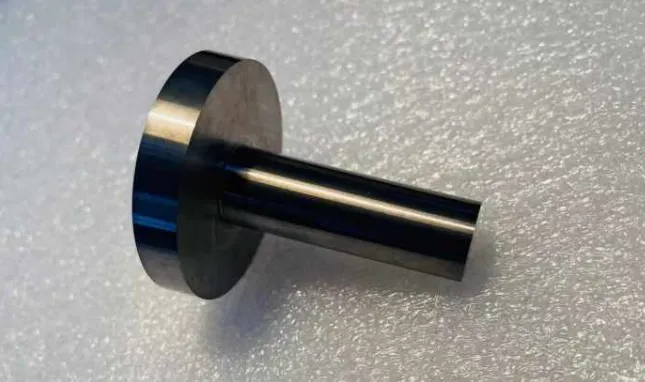

Rough blank for T-slot cutter

China Lizhou Hard Alloy Source Factory

Grade:T-slot end mill

Classification :

Carbide Rod

keyword:

lizhou

Product Name: T-Slot Milling Cutter

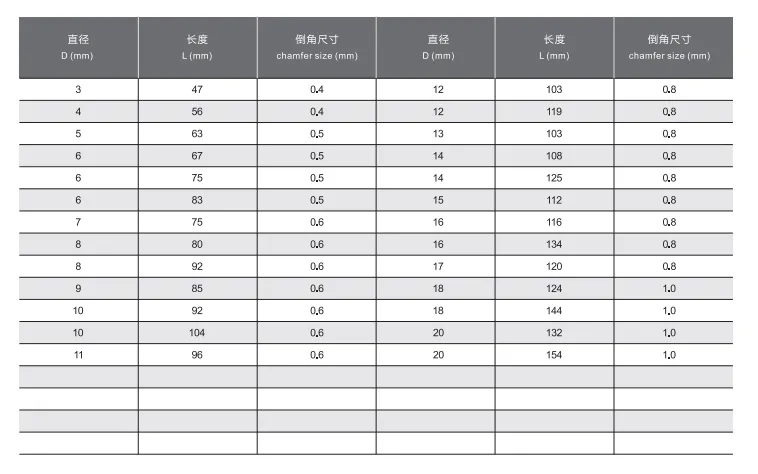

Processing Range: Diameter φ15-φ32mm, Length 100-160mm, other sizes can be customized according to drawings

Diameter +0.4/0mm, Stepped Diameter D±0.3mm

Length +2.0/0mm, Stepped Length C+0.3mm

T-Slot Milling Cutter Blanks:

Lizhou T-slot milling cutter blanks are raw materials or semi-finished products that have not yet undergone final processing. They are usually cylindrical bars that require further processing to become cutting tools.

T-Slot End Mill Blanks

Characteristics of T-Slot Milling Cutter Blanks:

1. Structure: No cutting edges, rough surface, requires grinding or milling to form cutting edges and tooth shape

2. Not Heat-Treated: May be in an annealed or tempered state, requires quenching, tempering, etc., according to final performance requirements

Uses: Customizable non-standard blades (such as special sizes, tooth shapes)

T-Slot Milling Cutter:

Lizhou T-slot milling cutters are finished cutting tools that have completed all processing steps and can be used directly to machine T-slots or other similar structures

Characteristics of T-Slot Milling Cutters:

1. Complete Structure: Has cutting edges, heat-treated (such as quenching), surface coating (such as TiN\TiAIN), etc.

2. Milling Cutter Parameters: Diameter, number of teeth, blade length, etc., specifications are clearly defined, suitable for standard T-slot sizes

Uses: Used for machining T-slots, dovetail slots, internal slots, etc., commonly used in machine tool worktables, fixtures, molds, etc.

Lizhou cemented carbide manufacturers can produce T-slot milling cutter tools and T-slot milling cutter blanks. Please contact us if you have any needs.

Previous page

Next page

Use equipment

CNC machining centre

CNC machine tools

Carved machine

Factory Board

Factory Board

Factory Board

Factory Board

Factory Board

Recommended products

FAQ

2025-12-12

Lizhou Indexable U-Drill Series | High-Speed Drilling Solution for Large-Hole U-Drills

The Lizhou U-drill series is suitable for large-hole drilling in a variety of materials, including steel, stainless steel, alloy steel, and titanium alloys. It offers two structural types: square U-drills and peach-shaped U-drills. These drills combine rigidity, centering accuracy, and chip-removal efficiency, enabling multi-process machining that includes drilling, boring, and chamfering. Featuring high-quality carbide inserts and a stable tool body design, this series ensures more efficient batch drilling at lower costs.

2025-12-12

Lizhou Carbide Turning Inserts Series | Cemented Carbide CNC Turning Solutions

The Lizhou carbide turning blade series specializes in CNC turning applications using cemented carbide, covering common machining operations such as external cylindrical turning, end-face turning, roughing, and finishing. We offer diamond-shaped blades, square blades, triangular blades, peach-shaped blades, and peel-off blades, each tailored with specific grades and flute geometries for materials including cast iron, steel, stainless steel, high-hardness steel, and copper and aluminum. These blades help workshops enhance tool life and improve machining stability.

2025-12-12

Lizhou Threaded Blade Series | High-Precision, Stable Thread-Machining Solution

The Lizhou thread cutting blades are made from high-quality cemented carbide materials, combined with advanced coatings and precise tooth profile grinding, enabling them to meet the machining requirements of various thread standards. Whether working with steel, stainless steel, or high-temperature alloys, these blades maintain excellent wear resistance and cutting stability, making them ideal for mass production and thread machining applications that demand high consistency.

2025-12-12

Lizhou Solid Carbide End Mill Series | GX GG BS TS AL Milling Solutions

The Lizhou end-mill series covers a wide range of materials, including steel, stainless steel, quenched and tempered steel, aluminum alloys, and titanium alloys, and corresponds to five major carbide end-mill lines: GX, GG, BS, TS, and AL. Available in flat-end, round-nose, ball-nose, and multi-flute configurations, these end mills are suitable for roughing, finishing, and high-speed machining. Featuring an ultra-fine-grain matrix and comprehensive quality control throughout the entire manufacturing process, these tools deliver more stable tool life and smoother machining performance.