Product

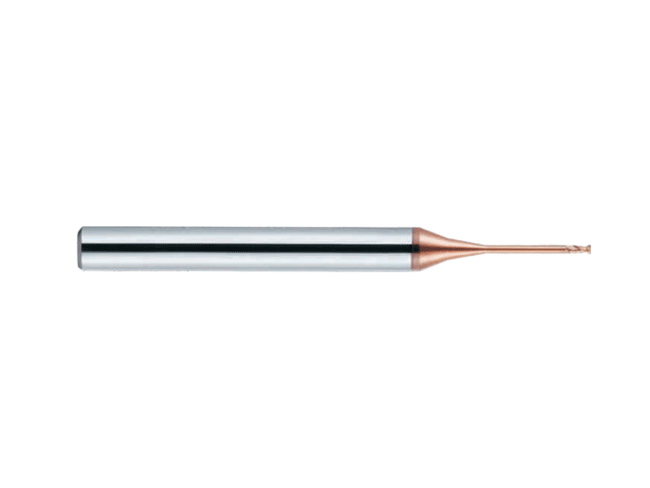

4-Flute Corner Radius End Mill

China Lizhou Hard Alloy Source Factory

| Blade count and type: 4 flute Corner Radius end mill Product model (brand):MS-4R Suitable for processing materials:Cast iron, steel, stainless steel |

||

Classification :

Corner Radius End Mill

keyword:

lizhou

4-Flute Corner Radius End Mill: Precision, Durability, and Performance for Advanced Milling Applications

Introduction

In modern machining, manufacturers constantly seek tools that balance precision, durability, and efficiency. One of the most widely used and highly reliable tools in metalworking is the 4-Flute Corner Radius End Mill. As a professional carbide tool manufacturer, our company specializes in producing high-performance cutting tools that deliver excellent results across various industries.

The 4-Flute Corner Radius End Mill represents a hybrid design between a flat end mill and a ball end mill, featuring a slight radius at the corner of the cutting edge. This unique geometry enhances tool strength, reduces chipping, and improves the surface finish of machined parts. When manufactured from premium-grade carbide materials, this tool ensures superior performance in both roughing and finishing operations.

This article explores the advantages of carbide, the applications, functions, features, precautions, and the innovations behind our 4-Flute Corner Radius End Mill.

1. Advantages of Carbide in Cutting Tools

Carbide (tungsten carbide with cobalt binder) has become the industry standard for high-performance cutting tools. Compared with high-speed steel (HSS) or cobalt tools, carbide offers distinct advantages:

Exceptional Hardness: Carbide tools maintain sharp cutting edges even under extreme conditions.

High Wear Resistance: Longer tool life reduces tool replacement frequency and costs.

Thermal Stability: Carbide withstands higher cutting temperatures without losing hardness.

Faster Machining Speeds: Allows higher RPMs and feed rates, significantly improving productivity.

Consistency in Production: Ensures dimensional accuracy and precision over long production runs.

By manufacturing the 4-Flute Corner Radius End Mill from fine-grain carbide, we provide a tool that meets the demands of high-performance CNC machining across industries like aerospace, mold manufacturing, and precision engineering.

2. Role and Function of the 4-Flute Corner Radius End Mill

The corner radius design sets this tool apart from standard flat end mills. Its slightly rounded cutting edges provide the following functional benefits:

Strengthened Corners: The radius reduces the stress concentration at the cutting edge, minimizing tool breakage.

Improved Surface Finish: Produces smoother transitions and reduces tool marks on workpieces.

Extended Tool Life: Lower risk of chipping means longer usage per tool.

Versatility: Suitable for both roughing and finishing operations.

Reduced Burr Formation: Especially important in aluminum and softer alloys.

This makes the 4-Flute Corner Radius End Mill a preferred choice for machinists who require durable and precise tools for complex machining operations.

3. Key Features of the 4-Flute Corner Radius End Mill

Four Cutting Flutes:

Provide excellent balance between material removal rate and tool stability.

Enable smooth cutting with reduced vibrations.

Support higher feed rates compared to 2-flute or 3-flute designs.

Corner Radius Geometry:

Protects the cutting edge from premature chipping.

Improves the strength of the tool for heavy-duty applications.

Creates smooth blending surfaces in pocketing and contouring operations.

Premium Carbide Substrate:

Ensures superior hardness and toughness.

Resistant to heat and abrasive wear.

Advanced Coating Options (TiAlN, AlTiN, DLC, etc.):

Reduce friction and heat generation.

Increase tool life under high-speed cutting conditions.

Optimize performance for different materials (steel, stainless steel, aluminum, titanium, etc.).

High Precision Manufacturing:

CNC grinding ensures consistent dimensions and accuracy.

Tolerance control guarantees repeatability in mass production.

4. Application Scenarios

The 4-Flute Corner Radius End Mill is highly versatile, making it suitable for a wide range of machining tasks and materials:

(1) Aerospace Industry

Machining titanium alloys, Inconel, and aluminum components.

Creating high-precision contours and smooth transitions in turbine blades and aerospace frames.

(2) Mold and Die Manufacturing

Perfect for mold cavities, pocketing, and finishing with enhanced tool life.

Reduces tool wear when machining hardened steels.

(3) Automotive Industry

Ideal for machining engine parts, transmission components, and aluminum molds.

Improves cycle time while maintaining part accuracy.

(4) Precision Engineering

Suitable for machining intricate parts requiring superior surface finishes.

Widely used in medical device manufacturing, robotics, and electronics.

(5) General Metalworking

Effective for slotting, contouring, pocket milling, and ramping.

Adaptable to materials such as carbon steel, stainless steel, aluminum alloys, and cast iron.

5. Benefits and Advantages

By choosing our 4-Flute Corner Radius End Mill, users can expect:

Reduced Tool Breakage: Stronger edges withstand demanding operations.

Lower Production Costs: Extended tool life minimizes downtime and tool replacement.

Improved Productivity: High-speed machining reduces cycle times.

Superior Surface Quality: Achieves smoother finishes compared to flat end mills.

Multi-Purpose Usage: Suitable for both roughing and finishing, reducing the need for multiple tools.

6. Precautions for Use

To maximize the performance and tool life of the 4-Flute Corner Radius End Mill, operators should follow these guidelines:

Select Proper Cutting Parameters

Adjust spindle speed, feed rate, and depth of cut according to the material being machined.

Use Proper Tool Holders

High-precision collets or shrink-fit holders reduce runout and vibration.

Apply Coolant When Necessary

For aluminum and softer alloys, coolant helps prevent chip welding.

For steels and superalloys, coolant reduces heat buildup.

Avoid Excessive Overhang

Shorter tool stick-out increases stability and minimizes chatter.

Inspect and Replace Tools Timely

Dull or worn tools compromise surface finish and may damage the workpiece.

7. Technical Innovation and Patented Design

As a carbide manufacturer, our company continuously invests in R&D and innovation to ensure our products lead the industry. The 4-Flute Corner Radius End Mill integrates several proprietary technologies:

Micro-Grain Carbide Substrate: Enhances toughness while maintaining high hardness.

Optimized Helix Design: Reduces cutting forces, improves chip evacuation, and minimizes vibration.

Advanced Coatings: Our in-house PVD and CVD coatings extend tool life significantly.

Precision Grinding Technology: Achieves micron-level dimensional accuracy.

These innovations not only improve tool performance but also help our clients reduce production costs and increase competitiveness.

8. Why Choose Our Company’s Carbide Tools?

As a dedicated carbide cutting tool manufacturer, we combine:

High-Quality Raw Materials: Only premium tungsten carbide powders are used.

Strict Quality Control: Each tool undergoes multiple inspections before delivery.

Customized Solutions: We provide OEM/ODM services tailored to specific machining needs.

Global Service: Our tools are trusted by clients across aerospace, automotive, mold, and precision industries worldwide.

By choosing our 4-Flute Corner Radius End Mill, customers are guaranteed superior performance, reliability, and cost-effectiveness.

Conclusion

The 4-Flute Corner Radius End Mill is an essential tool for machinists who demand strength, precision, and versatility in modern milling operations. Its unique design, combined with the benefits of carbide material and advanced coatings, ensures superior tool life and outstanding machining performance.

Whether for aerospace components, precision molds, automotive parts, or general metalworking, this tool delivers exceptional results. By incorporating advanced technologies and strict quality standards, our company ensures that every tool provides maximum efficiency and reliability.

If you are seeking a durable, high-performance carbide end mill that meets today’s demanding machining challenges, the 4-Flute Corner Radius End Mill is your ideal choice

Previous page

Next page

Use equipment

CNC machining centre

CNC machine tools

Carved machine

Factory Board

Factory Board

Factory Board

Factory Board

Factory Board

Recommended products

FAQ

2025-05-29

The naming conventions for turning inserts generally follow international standards (such as ISO standards). The model number consists of a series of letters and numbers, each character representing different geometric parameters or functional characteristics, such as the naming convention for the TNMG160404R-PV turning insert from Lizhou.

2025-05-26

What types of end mills are there?

Materials can be processed according to different types of end mills, categorized by the types of milling tools, including flat end mills, ball end mills, radius end mills, chamfer end mills, and end mills with chip breakers.

2025-05-23

PCD milling cutter is a polycrystalline diamond (PCD) milling cutter, which has a wide range of applications in the field of machining.

2025-05-08

End mill for machining aluminum materials

Many customers have told us that ordinary end mills frequently stick when machining aluminum, and the accumulation of chips affects the accuracy, so they always change the tools. LIZHOU editor suggests that coated end mills are not recommended for aluminum materials, because some coatings contain aluminum elements. Therefore, it is better to choose uncoated end mills when selecting end mills for machining aluminum materials.