Product

FAQ

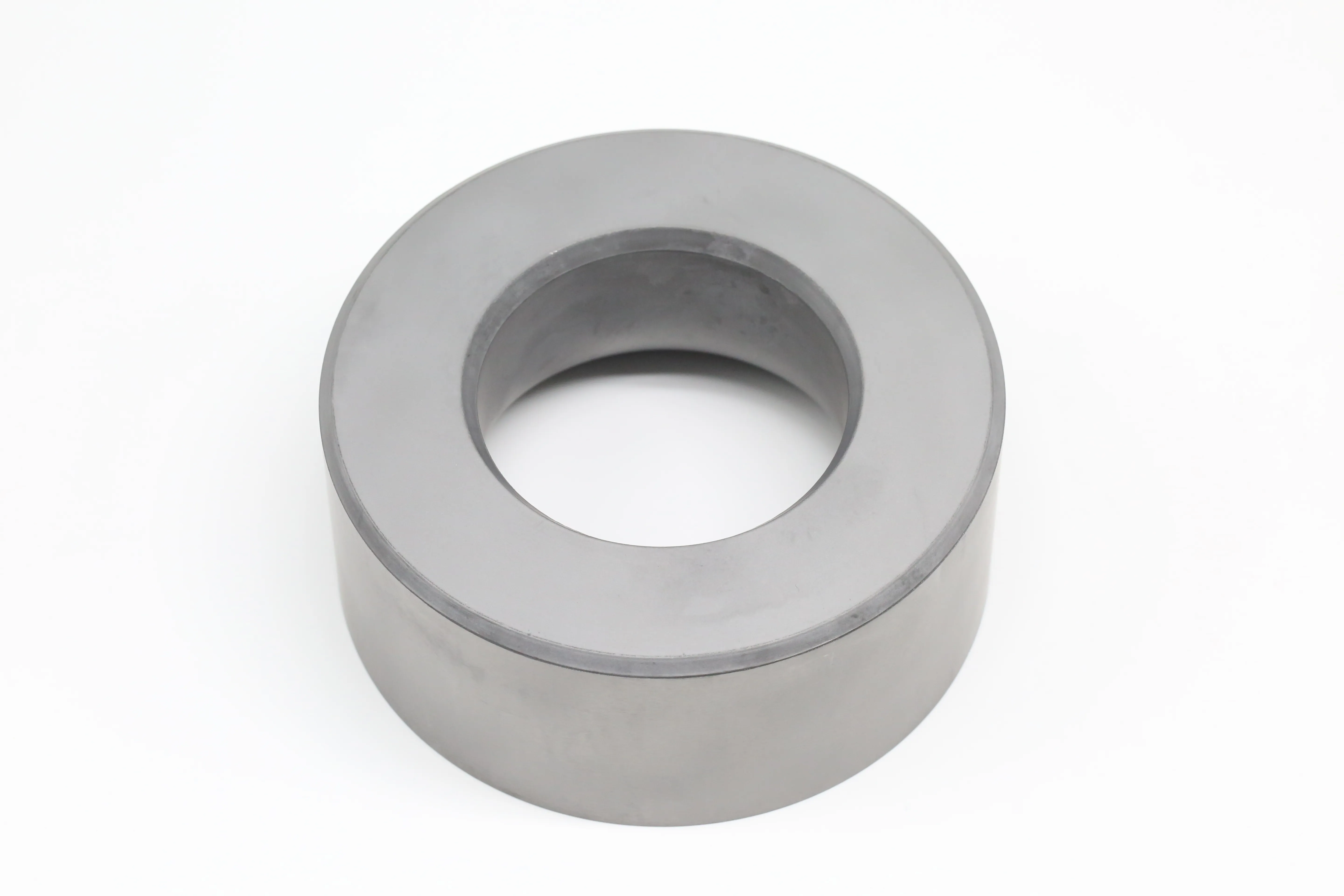

Hard alloy wire drawing die

China Lizhou Hard Alloy Source Factory

Classification :

Carbide Wire Drawing Die

keyword:

lizhou

Lizhou cemented carbide manufactures cemented carbide wire drawing dies. The tolerances of diameter and aperture can be controlled very small, and the aperture tolerance can be controlled within ±0.1 mm.

The inner diameter profile of the wire drawing die is very important. It determines the tension required to compress the metal wire and affects the residual stress of the metal wire after drawing.

As a professional cemented carbide manufacturer, we provide high-quality wire drawing dies to prevent the precision drawing of metal wires. Our products are made of high-hardness cemented carbide, with excellent wear resistance, ultra-long service life and high precision, providing a stable and efficient solution for your production.

Cemented Carbide Wire Drawing Die Size Table

Size |

Tolerance |

Size |

Tolerance |

> 16.0~24.0 |

0-0.50 |

||

≥ 0.4~0.6 |

0-0.08 |

> 24.0~32.0 |

0-0.60 |

> 0.6~3.0 |

0-0.18 |

> 32.0~40.0 |

0-0.80 |

> 3.0~6.0 |

0-0.25 |

> 40.0~55.0 |

0-1.20 |

> 6.0~9.0 |

0-0.30 |

> 55.0~90.0 |

0-1.50 |

> 9.0~16.0 |

> 90

|

0-2.0 |

|

|

|

|

|

Outer diameter unit: mm

Size |

Tolerance |

Size |

Tolerance |

≤ 10

|

± 0.15

|

> 35~40 |

± 0.40

|

> 10~16 |

± 0.2

|

> 40~45 |

± 0.50

|

> 16~30 |

± 0.3

|

> 45~50 |

± 0.60

|

> 30~35 |

± 0.4

|

> 50

|

± 1.3%D |

Product Applications

Metal wire manufacturing: effective processing of stainless steel wire, copper wire, aluminum wire, welding wire, etc.

Cable industry: precision drawing of cables, wires and communication lines

Fastener and spring manufacturing: producing high-strength wire to improve product stability

Aerospace and automotive industries: used for high-precision alloy wire drawing to ensure product quality

Use equipment

CNC machining centre

CNC machine tools

Carved machine

Factory Board

Factory Board

Factory Board

Factory Board

Factory Board

Recommended products

FAQ

2025-12-12

Lizhou Indexable U-Drill Series | High-Speed Drilling Solution for Large-Hole U-Drills

The Lizhou U-drill series is suitable for large-hole drilling in a variety of materials, including steel, stainless steel, alloy steel, and titanium alloys. It offers two structural types: square U-drills and peach-shaped U-drills. These drills combine rigidity, centering accuracy, and chip-removal efficiency, enabling multi-process machining that includes drilling, boring, and chamfering. Featuring high-quality carbide inserts and a stable tool body design, this series ensures more efficient batch drilling at lower costs.

2025-12-12

Lizhou Carbide Turning Inserts Series | Cemented Carbide CNC Turning Solutions

The Lizhou carbide turning blade series specializes in CNC turning applications using cemented carbide, covering common machining operations such as external cylindrical turning, end-face turning, roughing, and finishing. We offer diamond-shaped blades, square blades, triangular blades, peach-shaped blades, and peel-off blades, each tailored with specific grades and flute geometries for materials including cast iron, steel, stainless steel, high-hardness steel, and copper and aluminum. These blades help workshops enhance tool life and improve machining stability.

2025-12-12

Lizhou Threaded Blade Series | High-Precision, Stable Thread-Machining Solution

The Lizhou thread cutting blades are made from high-quality cemented carbide materials, combined with advanced coatings and precise tooth profile grinding, enabling them to meet the machining requirements of various thread standards. Whether working with steel, stainless steel, or high-temperature alloys, these blades maintain excellent wear resistance and cutting stability, making them ideal for mass production and thread machining applications that demand high consistency.

2025-12-12

Lizhou Solid Carbide End Mill Series | GX GG BS TS AL Milling Solutions

The Lizhou end-mill series covers a wide range of materials, including steel, stainless steel, quenched and tempered steel, aluminum alloys, and titanium alloys, and corresponds to five major carbide end-mill lines: GX, GG, BS, TS, and AL. Available in flat-end, round-nose, ball-nose, and multi-flute configurations, these end mills are suitable for roughing, finishing, and high-speed machining. Featuring an ultra-fine-grain matrix and comprehensive quality control throughout the entire manufacturing process, these tools deliver more stable tool life and smoother machining performance.