Product

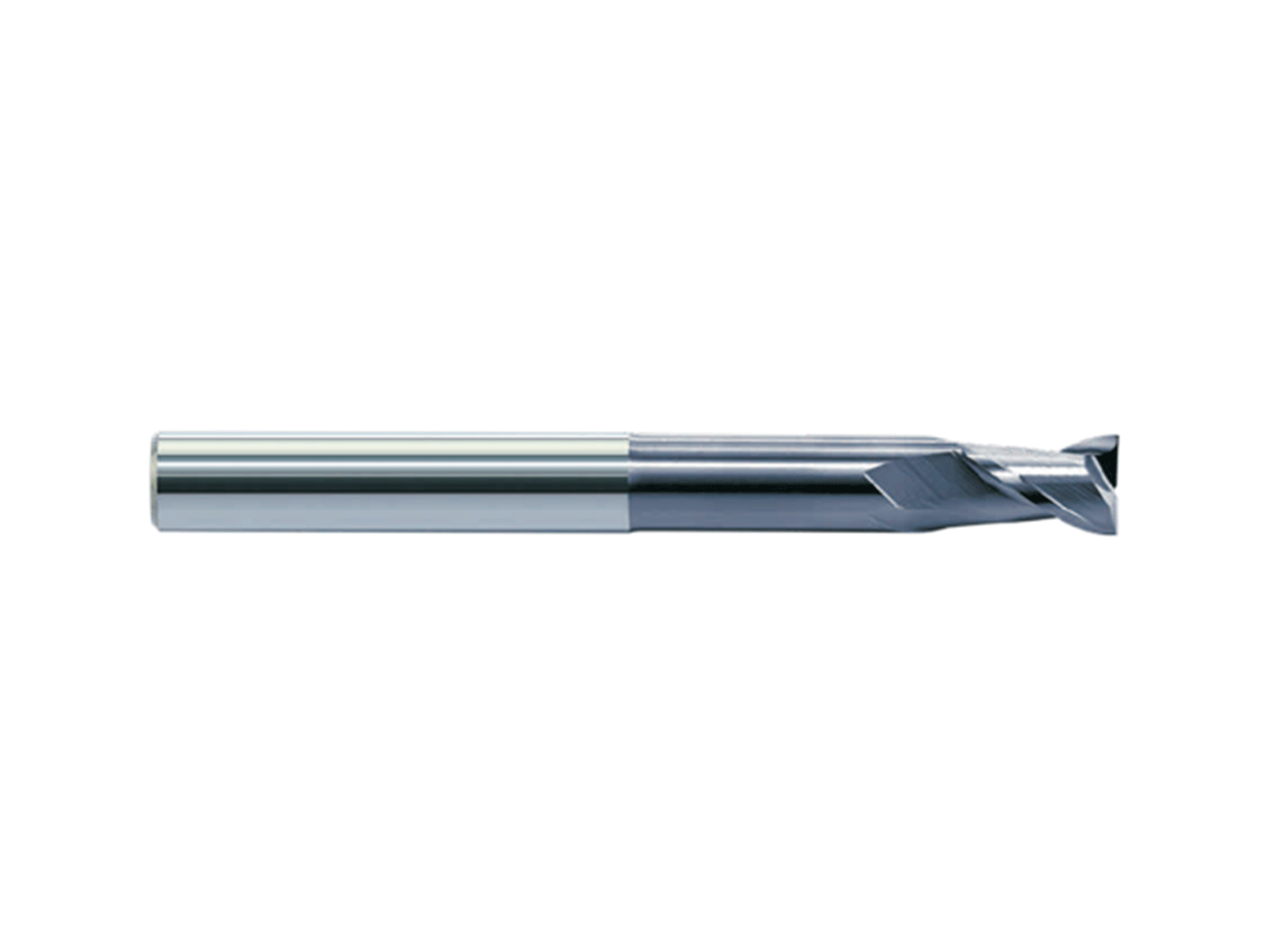

2-edge double-ended chamfering end mill

China Lizhou Hard Alloy Source Factory

Blade count and type: 2-edge double-ended chamfering end mill

Product model (brand):MS-2E

Suitable for processing materials:Cast iron, steel, stainless steel

Classification :

Chamfer End Mill

keyword:

lizhou

2-Edge Double-Ended Chamfering End Mill: Precision Carbide Tool for High-Performance Machining

Introduction

In the field of precision machining, chamfering plays a critical role in achieving smooth edges, enhancing assembly accuracy, and improving product aesthetics. Among the many chamfering tools available, the 2-Edge Double-Ended Chamfering End Mill has emerged as a top choice for manufacturers seeking efficiency, durability, and superior performance. Manufactured from premium tungsten carbide, this tool combines cutting-edge design with material advantages to meet the demands of modern industries such as aerospace, automotive, mold-making, and general metalworking.

This article explores in detail the advantages, applications, features, usage precautions, and technological innovations of the 2-Edge Double-Ended Chamfering End Mill, offering buyers and machining professionals valuable insights into why this tool should be their preferred solution for chamfering tasks.

Advantages of Carbide Tools in Chamfering Applications

The material of a cutting tool defines its durability, efficiency, and cost-effectiveness. Our 2-Edge Double-Ended Chamfering End Mill is manufactured from ultrafine-grain tungsten carbide, which delivers unmatched advantages compared to traditional high-speed steel (HSS) or coated alloy tools.

1. Exceptional Hardness and Wear Resistance

Carbide tools have a hardness level that is significantly higher than HSS, enabling them to withstand high-speed cutting and abrasive wear during prolonged operations. For chamfering, where the cutting edge continuously interacts with workpiece edges, this hardness translates to longer tool life and reduced replacement costs.

2. Superior Heat Resistance

During high-speed chamfering, cutting edges can reach extreme temperatures. Carbide retains its hardness even at elevated temperatures, minimizing edge deformation and ensuring consistent chamfer quality across extended runs.

3. High Precision and Surface Finish

The rigidity of carbide allows precise chamfer angles and smooth surfaces, essential for applications where parts must meet tight dimensional tolerances or require post-machining assembly.

4. Cost Efficiency with Double-Ended Design

Unlike single-ended chamfering tools, the double-ended configuration offers two cutting edges in one tool. When one edge becomes dull, operators can simply reverse the tool, effectively doubling tool life and reducing per-part machining costs。

Applications of 2-Edge Double-Ended Chamfering End Mill

The versatility of this tool makes it indispensable across a wide range of industries:

1. Aerospace Industry

Chamfering edges of lightweight aluminum or titanium parts.

Creating precise entry bevels to improve assembly of structural components.

Enhancing fatigue resistance by reducing stress concentration at sharp edges.

2. Automotive Industry

Deburring and chamfering engine components such as cylinder heads, valves, and crankshafts.

Ensuring smooth assembly of transmission and chassis parts.

Preparing components for welding or coating processes.

3. Mold and Die Making

Chamfering cavities and cores in hardened tool steel.

Improving mold release performance by smoothing sharp edges.

Ensuring consistent dimensions in high-volume plastic injection applications.

4. Precision Engineering & Electronics

Creating micro-chamfers on intricate parts.

Preparing edges for soldering or bonding in electronic device housings.

Enhancing product aesthetics with clean, burr-free edges.

5. General Metalworking

Ideal for chamfering steel, stainless steel, copper, brass, and aluminum alloys.

Used in deburring operations to prevent injury and ensure safety in handling parts.、

Functions and Benefits in Machining

The 2-Edge Double-Ended Chamfering End Mill is not only a tool for cutting—it improves efficiency and quality across the production process.

Chamfering: Produces accurate bevels on the edges of components for functional or decorative purposes.

Deburring: Eliminates sharp edges and burrs to improve safety and assembly compatibility.

Countersinking Preparation: Prepares holes for fasteners such as screws and bolts by creating the necessary angle.

Edge Strengthening: Removes stress concentrations, increasing the mechanical strength and fatigue resistance of parts.

Cost Optimization: Double-ended design lowers the cost-per-edge compared to traditional single-use tools.

Key Features of the 2-Edge Double-Ended Chamfering End Mill

Double-Ended Design

Provides two cutting edges in one tool.

Reduces tool change frequency, minimizing machine downtime.

2-Flute Geometry

Ensures excellent chip evacuation during cutting.

Reduces heat buildup, prolonging tool life.

Delivers smooth chamfer finishes, particularly in aluminum and non-ferrous metals.

Carbide Material

Offers hardness of 90+ HRA.

Performs reliably in high-speed machining (HSM) environments.

Versatile Cutting Angles

Available in common chamfering angles (30°, 45°, 60°, etc.) to meet diverse production needs.

Universal Application

Suitable for CNC machining centers, milling machines, and manual operations.

Usage Precautions

Although carbide chamfering tools deliver superior performance, following best practices ensures maximum efficiency and tool longevity:

Optimal Cutting Parameters

Use appropriate spindle speeds and feed rates according to material hardness.

Excessive speed may cause premature edge wear, while low speeds may reduce efficiency.

Workpiece Clamping

Ensure the workpiece is rigidly secured to prevent vibrations, which can lead to poor chamfer finish or tool chipping.

Coolant and Lubrication

For aluminum and copper, cutting fluids help prevent material adhesion.

For steels, flood cooling extends tool life by reducing heat.

Tool Handling

Avoid mechanical shock when installing the tool.

Always inspect edges for wear before reuse.

Angle Selection

Choose the correct chamfer angle based on assembly requirements and design specifications.

Technological and Innovative Aspects

Our carbide 2-Edge Double-Ended Chamfering End Mill integrates modern manufacturing technologies:

Micro-Grain Carbide Substrate

Improves fracture toughness and wear resistance.

Enables machining of hardened steels up to HRC 55.

Advanced CNC Grinding

Guarantees precise geometry and edge sharpness.

Provides consistent chamfer dimensions across batches.

Optional Coatings

TiAlN (Titanium Aluminum Nitride): High oxidation resistance for steel and stainless steel.

DLC (Diamond-Like Carbon): Ideal for non-ferrous metals, prevents built-up edge (BUE).

Uncoated version available for aluminum and soft metals.

Patented Double-Ended Design

Maximizes tool usage efficiency.

Reduces cost per chamfered edge, aligning with sustainable manufacturing practices.

Why Choose Our Carbide Chamfering End Mills?

Proven Quality: Manufactured under ISO- certified processes.

Customization:Available in multiple diameters,lengths,and chamfer angles.

Global compatibility:Designed for use in both metric and imperial machining systems.

R&D Driven: Continuous innovatian ensures our tools meet the evolving needs of precision industries.

Conclusion

The 2-Edge Double-Ended Chamfering End Mill stands out as a versatile, cost-efficient, and high-performance tool in modern machining. Its carbide construction, double-ended design, and precision engineering deliver superior durability and finish quality across a wide range of materials and applications.

By reducing production costs, extending tool life, and ensuring consistent chamfer quality, this tool represents a smart investment for manufacturers aiming to improve machining efficiency and product performance. Whether in aerospace, automotive, mold-making, or general engineering, our chamfering end mill is engineered to exceed expectations and provide sustainable value.

Use equipment

CNC machining centre

CNC machine tools

Carved machine

Factory Board

Factory Board

Factory Board

Factory Board

Factory Board

Recommended products

FAQ

2025-05-29

The naming conventions for turning inserts generally follow international standards (such as ISO standards). The model number consists of a series of letters and numbers, each character representing different geometric parameters or functional characteristics, such as the naming convention for the TNMG160404R-PV turning insert from Lizhou.

2025-05-26

What types of end mills are there?

Materials can be processed according to different types of end mills, categorized by the types of milling tools, including flat end mills, ball end mills, radius end mills, chamfer end mills, and end mills with chip breakers.

2025-05-23

PCD milling cutter is a polycrystalline diamond (PCD) milling cutter, which has a wide range of applications in the field of machining.

2025-05-08

End mill for machining aluminum materials

Many customers have told us that ordinary end mills frequently stick when machining aluminum, and the accumulation of chips affects the accuracy, so they always change the tools. LIZHOU editor suggests that coated end mills are not recommended for aluminum materials, because some coatings contain aluminum elements. Therefore, it is better to choose uncoated end mills when selecting end mills for machining aluminum materials.