Product

FAQ

3-Flute Flat End Mill-Aluminum end mills

China Lizhou Hard Alloy Source Factory

Classification :

Carbide End Mill Featured Products

keyword:

lizhou

Carbide 3-Flute Flat End Mill for Aluminum – Precision Tool for High-Performance Machining

Introduction

Aluminum is one of the most widely used materials in industries ranging from aerospace and automotive to electronics and general manufacturing. Its softness, ductility, and high thermal conductivity make it a versatile choice but also introduce challenges during machining. Standard cutting tools often face issues such as built-up edge (BUE), chip welding, and poor surface finishes when working with aluminum.

To address these challenges, our company offers the Carbide 3-Flute Flat End Mill for Aluminum, engineered with superior carbide materials, optimized flute geometry, and advanced coatings. This tool is designed to deliver high-speed machining (HSM), excellent chip evacuation, and superior surface finishes

Order number | Basic dimensions (mm) | Drawing number | |||

D | d | H | L | ||

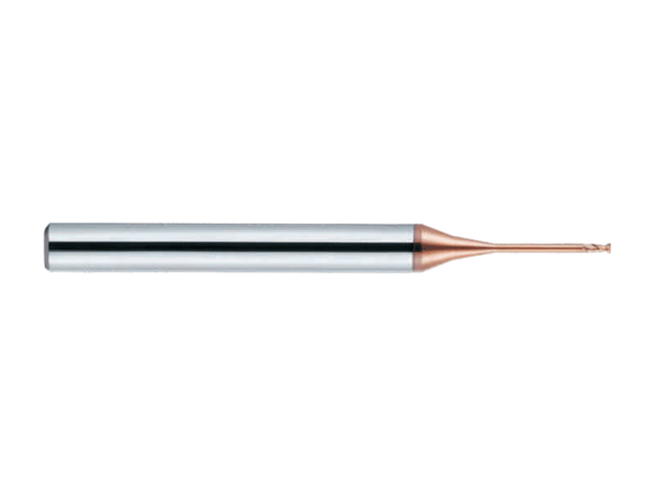

AL-3E-D1.0 | 1.0 | 4.0 | 3.0 | 50 | Fig 1 |

AL-3E-D2.0 | 2.0 | 4.0 | 6.0 | 50 | Fig 1 |

AL-3E-D3.0 | 3.0 | 6.0 | 9.0 | 50 | Fig 1 |

AL-3E-D4.0 | 4.0 | 6.0 | 12.0 | 50 | Fig 1 |

AL-3E-D6.0 | 6.0 | 6.0 | 18.0 | 60 | Fig 2 |

AL-3E-D8.0 | 8.0 | 8.0 | 20.0 | 60 | Fig 2 |

AL-3E-D10.0 | 10.0 | 10.0 | 30.0 | 75 | Fig 2 |

AL-3E-D12.0 | 12.0 | 12.0 | 32.0 | 75 | Fig 2 |

AL-3E-D16.0 | 16.0 | 16.0 | 45.0 | 100 | Fig 2 |

AL-3E-D20.0 | 20.0 | 20.0 | 45.0 | 100 | Fig 2 |

2. Recommended cutting parameters:

Workpiece Material | Aluminum alloy | Si ≤ 10% Silumin | ||

Diameter(mm) | Rotate speed(min) | Feed velocity(mm/min) | Rotate speed(min) | Feed velocity(mm/min) |

1 | 40000 | 800 | 40000 | 600 |

2 | 40000 | 1200 | 32000 | 900 |

3 | 26500 | 1800 | 21000 | 1300 |

4 | 20000 | 2000 | 16000 | 1500 |

6 | 13000 | 1500 | 10600 | 1200 |

8 | 10000 | 1650 | 8000 | 1390 |

10 | 8000 | 1900 | 6500 | 1500 |

12 | 6600 | 1950 | 5300 | 1550 |

16 | 5000 | 2000 | 4000 | 1600 |

20 | 4400 | 2000 | 3500 | 1600 |

Advantages of Carbide Tools

Before diving into the unique benefits of the 3-flute flat end mill for aluminum, it is essential to highlight why carbide tools are the industry standard:

Exceptional Hardness and Wear Resistance

Cemented carbide offers a much higher hardness level than HSS (high-speed steel), making it resistant to wear even under high cutting speeds.

Heat Resistance

Carbide maintains cutting performance at elevated temperatures, critical when machining aluminum at high spindle speeds.

Long Tool Life

Carbide tools generally last 5–10 times longer than conventional steel-based tools, reducing tooling costs over time.

Dimensional Stability

Carbide ensures precision tolerances, crucial for industries where accuracy is non-negotiable (e.g., aerospace parts, molds, and medical components).

Why Choose a 3-Flute Flat End Mill for Aluminum?

Unlike steel machining, aluminum machining requires specialized tool geometry. The 3-flute flat end mill strikes the perfect balance between chip evacuation, rigidity, and cutting efficiency.

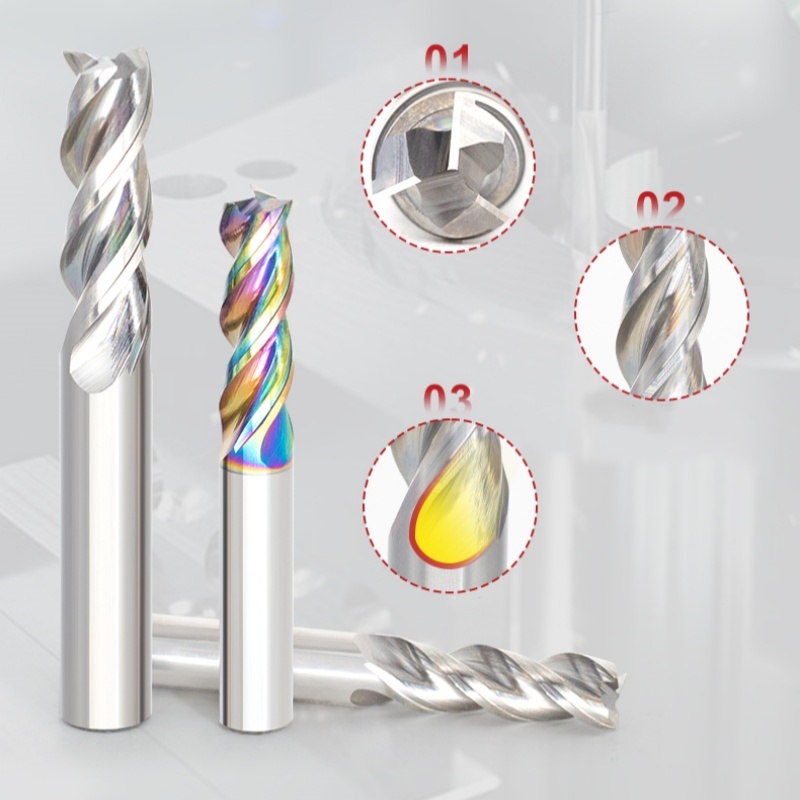

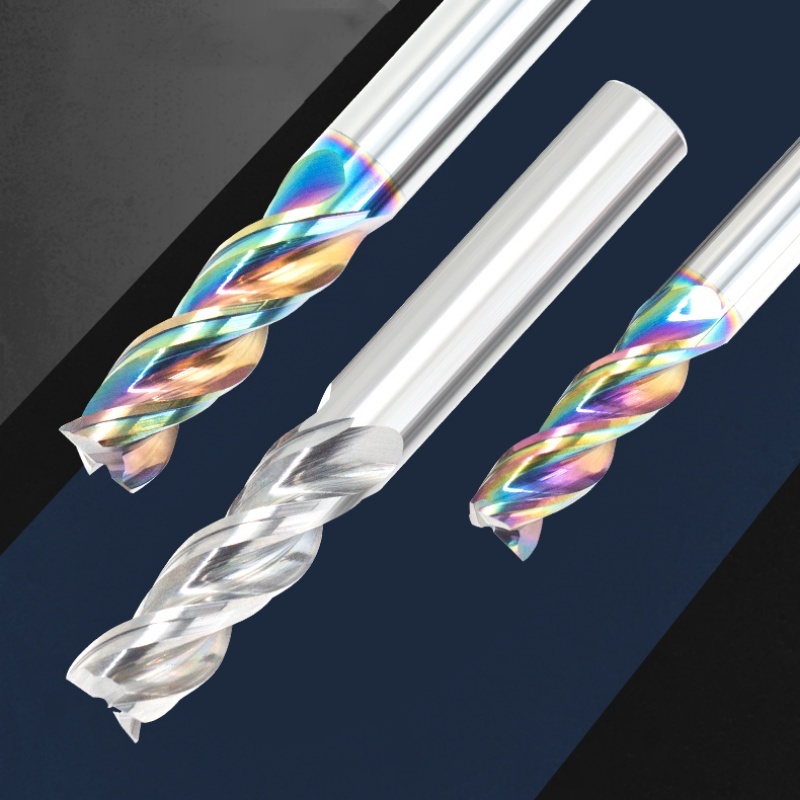

1. Optimized Flute Design

Three flutes provide more cutting edges than a 2-flute end mill, which increases feed rates.

Compared to a 4-flute tool, the 3-flute version leaves more space in the flute valley, improving chip evacuation and reducing clogging – a common problem with gummy aluminum.

2. High-Speed Machining Capability

Designed for CNC milling at very high spindle speeds (15,000–40,000 RPM).

Enables aggressive material removal without compromising surface finish.

3. Flat End Geometry

Creates sharp edges and perfect 90° walls and slots.

Ensures flat-bottom profiles for pocket milling, facing, and contouring in aluminum parts.

4. Superior Chip Evacuation

Wider flute spacing reduces chip re-cutting, minimizing tool wear.

Smooth flute polishing prevents chip adhesion to the cutting edge.

5. Coating Options

Uncoated carbide: Suitable for high-purity aluminum alloys.

ZrN (Zirconium Nitride) or DLC coatings: Reduce built-up edge and improve lubricity.

Application Scenarios

The Carbide 3-Flute Flat End Mill for Aluminum is versatile and widely used in industries requiring precision machining of aluminum alloys:

Aerospace Industry

Milling structural aluminum components such as frames, ribs, and skin panels.

High-speed contouring and pocketing operations.

Automotive Industry

Engine components, housings, and prototype molds.

Aluminum wheels, brackets, and gearbox housings.

Electronics and Semiconductors

Milling lightweight aluminum casings for laptops, smartphones, and electronic enclosures.

General Manufacturing

High-volume production of aluminum fixtures, plates, and industrial components.

Mold and Die Industry

Aluminum injection molds and prototype tooling.

Key Features and Benefits

1. High Material Removal Rate (MRR)

Achieve aggressive feed rates without chatter.

Suitable for both roughing and finishing operations.

2. Smooth Surface Finish

Eliminates burrs and reduces polishing time.

Ideal for applications demanding mirror-like finishes on aluminum parts.

3. Reduced Built-Up Edge (BUE)

Special flute geometry prevents aluminum from welding onto the cutting edge.

Coatings further reduce adhesion.

4. Extended Tool Life

High-quality carbide substrate withstands wear and deformation.

Reduces downtime and tooling costs.

5. Versatility in Cutting Strategies

Works for slotting, side milling, pocketing, and ramping.

Effective in both conventional machining and high-speed CNC applications.

Technical Considerations and Best Practices

To maximize the performance of carbide 3-flute end mills for aluminum, machinists should consider the following:

Cutting Speed & Feed Rate

Aluminum allows very high cutting speeds (300–1000 SFM).

Use higher feed per tooth compared to steel machining.

Coolant Application

Flood coolant or mist lubrication is recommended.

Reduces heat buildup and prevents aluminum welding on cutting edges.

Tool Holding

Use high-precision tool holders (hydraulic chucks, shrink-fit) for stability.

Reduces runout, ensuring dimensional accuracy.

Workholding

Secure aluminum workpieces firmly, as lightweight material can vibrate under aggressive cutting conditions.

Avoid Overloading

Proper step-over and depth of cut prevent tool breakage.

Recommended DOC: 0.5–1.5 times tool diameter depending on rigidity.

Technical Innovations & Patents

Our Carbide 3-Flute Flat End Mill for Aluminum integrates proprietary advancements:

Nano-grain carbide substrate for enhanced toughness and edge sharpness.

Mirror-polished flutes that reduce friction and improve chip evacuation.

ZrN & DLC coatings specifically tailored for aluminum, resisting built-up edge formation.

Optimized helix angle (35°–45°) to balance cutting force and chip clearance.

Optional through-tool coolant holes for high-speed machining centers.

These innovations not only improve productivity but also extend the cutting tool’s lifespan, making it a cost-effective solution for manufacturers.

Safety and Usage Precautions

Always inspect tools before use for cracks or wear

Ensure proper tool clamping to avoid vibarations

Follow recommended cutting parameteders to prevent premature failure

Use protective gear(gloves,goggles) when handling carbide tools.

Dispose of worn-out carbide tools properly , as they can often be recycled

Why Choose Our Company’s Carbide Tools?

As a professional carbide tool manufacturer, we specialize in designing, producing, and supplying precision cutting tools for global industries. Our competitive advantages include:

High-quality raw materials: Ultra-fine carbide powders and advanced sintering technology.

Customized solutions: Tailored flute geometry and coatings for specific applications.

Strict quality control: ISO-certified production with advanced inspection equipment.

Global reach: Supplying aerospace, automotive, and mold industries worldwide.

Conclusion

The Carbide 3-Flute Flat End Mill for Aluminum is a vital tool for manufacturers who demand speed, precision, and cost efficiency in aluminum machining. With its optimized design, superior carbide substrate, advanced coatings, and innovative technology, this end mill ensures excellent performance across diverse applications.

By choosing our carbide tools, customers benefit from longer tool life, reduced cycle times, and superior part quality, ultimately driving productivity and profitability in competitive industries.

Previous page

Next page

Use equipment

CNC machining centre

CNC machine tools

Carved machine

Factory Board

Factory Board

Factory Board

Factory Board

Factory Board

Recommended products

FAQ

2025-12-12

Lizhou Indexable U-Drill Series | High-Speed Drilling Solution for Large-Hole U-Drills

The Lizhou U-drill series is suitable for large-hole drilling in a variety of materials, including steel, stainless steel, alloy steel, and titanium alloys. It offers two structural types: square U-drills and peach-shaped U-drills. These drills combine rigidity, centering accuracy, and chip-removal efficiency, enabling multi-process machining that includes drilling, boring, and chamfering. Featuring high-quality carbide inserts and a stable tool body design, this series ensures more efficient batch drilling at lower costs.

2025-12-12

Lizhou Carbide Turning Inserts Series | Cemented Carbide CNC Turning Solutions

The Lizhou carbide turning blade series specializes in CNC turning applications using cemented carbide, covering common machining operations such as external cylindrical turning, end-face turning, roughing, and finishing. We offer diamond-shaped blades, square blades, triangular blades, peach-shaped blades, and peel-off blades, each tailored with specific grades and flute geometries for materials including cast iron, steel, stainless steel, high-hardness steel, and copper and aluminum. These blades help workshops enhance tool life and improve machining stability.

2025-12-12

Lizhou Threaded Blade Series | High-Precision, Stable Thread-Machining Solution

The Lizhou thread cutting blades are made from high-quality cemented carbide materials, combined with advanced coatings and precise tooth profile grinding, enabling them to meet the machining requirements of various thread standards. Whether working with steel, stainless steel, or high-temperature alloys, these blades maintain excellent wear resistance and cutting stability, making them ideal for mass production and thread machining applications that demand high consistency.

2025-12-12

Lizhou Solid Carbide End Mill Series | GX GG BS TS AL Milling Solutions

The Lizhou end-mill series covers a wide range of materials, including steel, stainless steel, quenched and tempered steel, aluminum alloys, and titanium alloys, and corresponds to five major carbide end-mill lines: GX, GG, BS, TS, and AL. Available in flat-end, round-nose, ball-nose, and multi-flute configurations, these end mills are suitable for roughing, finishing, and high-speed machining. Featuring an ultra-fine-grain matrix and comprehensive quality control throughout the entire manufacturing process, these tools deliver more stable tool life and smoother machining performance.