Product

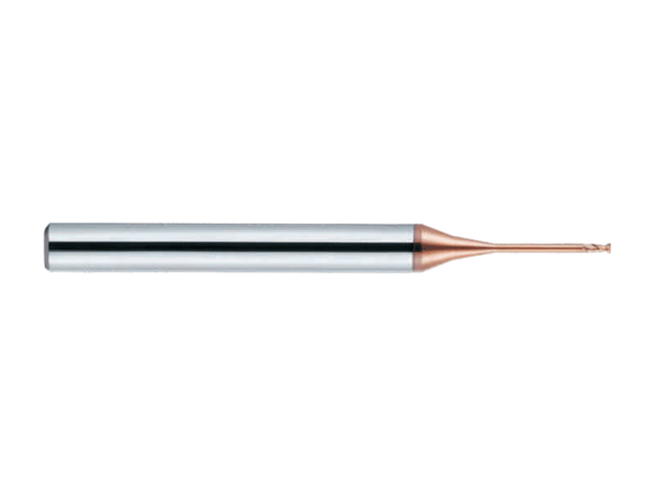

6-Flute Flat End Mill

China Lizhou Hard Alloy Source Factory

Blade count and type: 6 flute flat end mill

Product model (brand):MS-6E

Suitable for processing materials:Cast iron, steel, stainless steel

Classification :

Flat End Mill

keyword:

lizhou

Introduction

In modern machining, the demand for precision, speed, and durability continues to grow across industries such as aerospace, mold manufacturing, automotive, energy, and general engineering. Among the wide range of cutting tools available, carbide end mills have emerged as the standard for high-performance milling operations.

Within this family of tools, the carbide 6-flute flat end mill stands out as a reliable solution designed for heavy-duty, high-efficiency milling applications. Combining advanced carbide substrate technology with optimized geometry, the 6-flute end mill provides enhanced productivity, longer tool life, and superior surface finishes.

This article explores the advantages, applications, functions, features, precautions, and technical innovations behind the carbide 6-flute flat end mill.

Advantages of square end milling cutter as a Material

Carbide, also known as tungsten carbide (WC), is a hard material made by powder metallurgy. When used in cutting tools, it offers several unique advantages:

Extreme Hardness and Wear Resistance

Carbide has a hardness of approximately 90 HRA, significantly higher than high-speed steel (HSS). This ensures outstanding resistance against wear and deformation under extreme cutting conditions.

High Red Hardness

Carbide retains its hardness at elevated temperatures (up to 1000°C). This allows the 6-flute end mill to perform well in high-speed machining without losing cutting ability.

Excellent Tool Life

Due to its superior hardness and thermal stability, carbide tools generally last 5–10 times longer than HSS tools, reducing downtime and tool replacement costs.

Tight Dimensional Accuracy

Carbide tools allow precise machining with tolerances in the micrometer range, ensuring consistency in high-value manufacturing.

Why Choose a 6-Flute Flat End Mill?

The geometry of the cutting tool determines its suitability for different machining operations. Compared to 2-flute, 3-flute, or 4-flute end mills, the 6-flute flat end mill offers distinct advantages:

Higher Metal Removal Rate (MRR)

With six cutting edges engaged, the tool removes more material per revolution, enhancing machining efficiency.

Better Surface Finish

The additional flutes distribute cutting forces more evenly, reducing chatter and producing smoother surfaces.

Longer Tool Life

Cutting loads are shared across six edges instead of fewer flutes, which reduces tool wear and extends service life.

Optimized for Hard Materials

6-flute designs are particularly effective for machining hardened steels, titanium alloys, and superalloys, where higher rigidity and stability are required.

Improved Stability

The higher flute count reduces tool deflection, making it ideal for applications requiring dimensional precision.

Applications of the Carbide 6-Flute Flat End Mill

The 6-flute carbide flat end mill finds applications in multiple industries due to its versatility and robustness. Key application areas include:

Aerospace Industry

Machining titanium alloys, nickel-based superalloys, and aluminum parts.

Used for structural components requiring tight tolerances.

Automotive Manufacturing

Precision machining of engine components, transmission parts, and mold tools.

High-speed milling of hardened steels for dies and molds.

Mold & Die Industry

Used in roughing and finishing operations for injection molds and stamping dies.

Suitable for hardened steels (45–65 HRC).

General Engineering

Milling of stainless steel, cast iron, copper, and composite materials.

Fabrication of precision components in medical equipment and electronics.

Functions of the 6-Flute Flat End Mill

The carbide 6-flute flat end mill is designed for multiple milling operations:

Slotting – Creating accurate, flat-bottom slots.

Side Milling – Machining vertical or horizontal walls with precision.

Contour Milling – Following complex paths and 3D shapes.

Pocket Milling – Removing material within cavities.

Facing – Producing flat, smooth surfaces.

High-Efficiency Milling (HEM) – Removing material at high speeds while minimizing heat buildup.

Key Features

High-Performance Carbide Substrate

Manufactured with ultra-fine carbide particles to balance toughness and hardness.

Advanced Coatings (Optional)

TiAlN (Titanium Aluminum Nitride) for high-temperature resistance.

AlTiN (Aluminum Titanium Nitride) for excellent hardness and oxidation resistance.

DLC (Diamond-Like Coating) for non-ferrous applications.

Optimized Flute Design

Six flutes ensure smooth chip evacuation and reduced cutting forces.

Flat End Geometry

Enables sharp and clean bottom surfaces when slotting or pocketing.

Precision Manufacturing

Ground to exact tolerances with advanced CNC tool grinding equipment.

Precautions for Using Carbide 6-Flute End Mills

To maximize tool performance, users must follow certain precautions:

Machine Stability

Use rigid machines and fixtures to prevent chatter and tool breakage.

Correct Cutting Parameters

Use higher cutting speeds (Vc) compared to HSS tools.

Apply appropriate feed per tooth (fz) to avoid tool overload.

Coolant Usage

For steels and alloys, use coolant to reduce thermal stress.

For aluminum, apply minimum quantity lubrication (MQL) or air blast for chip evacuation.

Avoid Overloading

Do not use the 6-flute design for deep slotting in soft materials, as chips may clog the flutes.

Regular Inspection

Check for tool wear, edge chipping, or coating damage to maintain consistent machining quality.

Technical and Innovative Aspects

The development of carbide 6-flute end mills has evolved with technological advancements:

Nano-Grain Carbide

Ultra-fine carbide substrates improve toughness and reduce micro-chipping.

Advanced Coating Technologies

PVD and CVD coatings significantly increase wear resistance and extend tool life.

Variable Helix and Variable Pitch Designs

Reduce vibration and improve stability during high-speed milling.

Chipbreaker Geometries

Innovative flute geometries enhance chip evacuation in difficult-to-machine materials.

Patented Cooling Channels (Optional)

Some advanced designs feature internal coolant holes to deliver fluid directly to the cutting edge.

Conclusion

The carbide 6-flute flat end mill is a premium cutting tool designed to meet the demands of modern machining industries. With its durable carbide substrate, optimized geometry, and advanced coatings, it ensures long tool life, high productivity, and superior surface finishes.

From aerospace to automotive and mold manufacturing, this tool provides a competitive edge by delivering efficiency, accuracy, and reliability. By following best practices and using appropriate cutting parameters, manufacturers can maximize the performance of their 6-flute end mills and achieve significant cost savings.

Previous page

Next page

Use equipment

CNC machining centre

CNC machine tools

Carved machine

Factory Board

Factory Board

Factory Board

Factory Board

Factory Board

Recommended products

FAQ

2025-05-29

The naming conventions for turning inserts generally follow international standards (such as ISO standards). The model number consists of a series of letters and numbers, each character representing different geometric parameters or functional characteristics, such as the naming convention for the TNMG160404R-PV turning insert from Lizhou.

2025-05-26

What types of end mills are there?

Materials can be processed according to different types of end mills, categorized by the types of milling tools, including flat end mills, ball end mills, radius end mills, chamfer end mills, and end mills with chip breakers.

2025-05-23

PCD milling cutter is a polycrystalline diamond (PCD) milling cutter, which has a wide range of applications in the field of machining.

2025-05-08

End mill for machining aluminum materials

Many customers have told us that ordinary end mills frequently stick when machining aluminum, and the accumulation of chips affects the accuracy, so they always change the tools. LIZHOU editor suggests that coated end mills are not recommended for aluminum materials, because some coatings contain aluminum elements. Therefore, it is better to choose uncoated end mills when selecting end mills for machining aluminum materials.