Product

FAQ

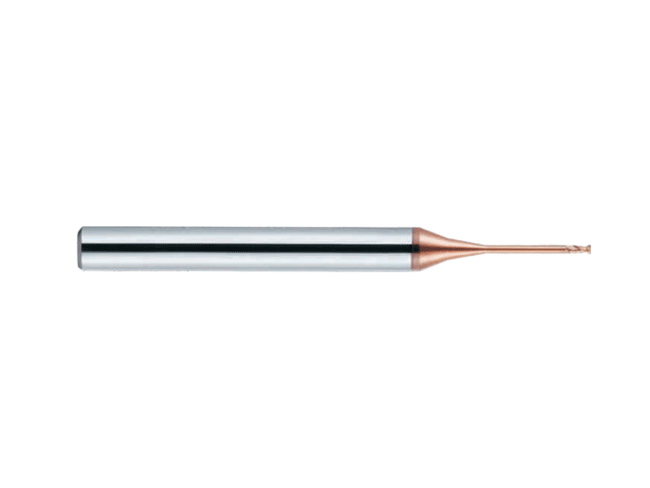

2-Flute Long Edge Ball End Mill

China Lizhou Hard Alloy Source Factory

Blade count and type: 2 flute ball nose end mill

Product model (brand):MS-2B

Suitable for processing materials:Cast iron, steel, stainless steel

Classification :

Carbide End Mill Featured Products

keyword:

lizhou

Carbide 2-Flute Long Neck Deep Groove Ball Nose End Mill: Precision Cutting for Complex Machining

Introduction

In modern CNC machining, the demand for precision, efficiency, and durability is higher than ever. Manufacturers working with molds, dies, aerospace parts, medical implants, and intricate components require tools that can handle deep grooves, complex contours, and high-performance cutting without compromising accuracy. This is where the Carbide 2-Flute Long Neck Deep Groove Ball Nose End Mill stands out.

As a professional carbide tool manufacturer, our company specializes in producing high-quality cutting tools designed for challenging machining applications. This specific tool is engineered to meet the needs of industries where accuracy, stability, and long tool life are critical. In this article, we will explore the advantages of carbide material, the applications, functions, and features of this end mill, as well as usage notes, innovative technologies, and patents that set our product apart.

Advantages of Carbide Material in End Mills

Carbide, or tungsten carbide (WC) cemented with cobalt, is one of the most widely used materials in high-performance cutting tools. Compared to high-speed steel (HSS) or other alloys, carbide offers multiple benefits:

Hardness and Wear Resistance

Carbide is significantly harder than HSS, maintaining cutting edges even under high-speed and heavy-duty machining conditions. This ensures longer tool life, reducing downtime and tooling costs.

Heat Resistance

Carbide end mills maintain stability at high cutting temperatures. When machining hard metals or long grooves, heat buildup is inevitable, but carbide resists thermal deformation, keeping cutting accuracy intact.

Superior Surface Finish

The hardness and sharpness of carbide cutting edges minimize burrs and deliver a smoother surface finish—essential for aerospace and mold-making industries.

Versatility

Carbide end mills can handle a wide range of materials: from aluminum and copper to hardened steels, titanium alloys, and composites. The 2-flute long neck deep groove ball nose end mill is especially effective for machining soft metals and difficult-to-reach areas.

Long-Term Cost Efficiency

While carbide tools are more expensive upfront than HSS, their longevity and performance reduce tool replacement frequency, providing better ROI for manufacturers.

Ball nose cutter

Product Overview: 2-Flute Long Neck Deep Groove Ball Nose End Mill

This tool is designed with precision engineering to solve challenges in machining deep cavities, narrow grooves, and complex 3D surfaces. The combination of ball nose geometry, long neck design, and 2-flute configuration makes it ideal for applications requiring both accuracy and accessibility.

Key Design Elements:

2-Flute Structure: Maximizes chip evacuation when cutting soft and sticky materials such as aluminum, copper, or plastics.

Ball Nose Tip: Enables contouring, profiling, and 3D surface machining with minimal tool marks.

Long Neck Design: Provides extended reach for deep grooves and pockets while avoiding tool interference.

Deep Groove Geometry: Specifically optimized for mold cavities, aerospace parts, and die-cutting operations.

Applications and Usage Scenarios

The Carbide 2-Flute Long Neck Deep Groove Ball Nose End Mill is widely used in industries that require precision contouring and deep cavity machining.

Mold and Die Industry

Used for machining deep cavities, mold bases, and fine details.

Perfect for 3D surface finishing and engraving in mold cores.

Aerospace Industry

Ideal for producing lightweight structural parts with deep ribs and grooves.

Handles materials like aluminum alloys, titanium, and Inconel efficiently.

Medical Device Manufacturing

Suitable for complex implants and instruments requiring precision contours.

Long neck and ball nose tip allow smooth finishing in small geometries.

Automotive Industry

Used for engine components, transmission molds, and die-casting cavities.

Ensures long-term tool stability under repetitive, high-speed machining.

General Precision Engineering

Engraving, 3D surface sculpting, and prototype machining.

Applicable for robotics, electronics, and energy sector components.

Functions and Roles of the Tool

The primary functions of the 2-Flute Long Neck Deep Groove Ball Nose End Mill include:

Deep Groove Machining: Its long reach design allows efficient machining of cavities and narrow channels without interference.

3D Surface Contouring: The ball nose geometry enables smooth finishing of curved and freeform surfaces.

Chip Evacuation: The 2-flute design ensures fast and efficient removal of chips, particularly important in aluminum machining.

Reduced Vibration: Carbide’s rigidity, combined with optimized tool geometry, minimizes tool chatter during long reach operations.

Precision Finishing: The smooth transition from roughing to finishing reduces secondary operations.

Features and Benefits

High-performance carbide substrate: manufactured from ultra -fine carbide for superior hardness and toughness

Polished flute surface: reduces friction and prevents chip adhesion,expecially when machining aluminum

Optimized Helix angle:enhances stability and cutting fluid penetration

Long Neck Geometry:Provides clearance for machining deep pockets while maintaining tool rigidity

Versatile Applications:suitable for roughing,Semi-finishing and finishing operations in aluminum,copper ,steels,and plastics

High Dimensional Accuracy:Tolerances within microns ensure precision machining of high-value parts.

Surface Treatment Options:Available with TiAIN,DLC,or diamond coatings for extended tool life in abrasive materials

Usage Notes and Best Practices

To maximize tool life and machining efficiency:

Select Proper Cutting Parameters

High spindle speed and low feed rate for aluminum.

Adjust speeds when working with harder alloys.

Use Appropriate Coolant

Apply mist or water-based coolant for chip evacuation and heat reduction.

Avoid dry machining in deep groove operations.

Maintain Stable Workholding

Use rigid fixtures to prevent vibration, especially in long neck machining.

Avoid Overloading

Limit axial depth of cut to prevent tool breakage.

Use step-down strategies for deep cavities.

Regular Tool Inspection

Check for edge wear, chipping, or breakage.

Replace tools before severe wear to maintain accuracy.

Technological and Patent Innovations

Our company integrates advanced R&D and patented manufacturing technologies into the production of carbide tools:

Nano-Coating Technology

Patented coating methods enhance wear resistance and reduce thermal stress.

Precision CNC Grinding

5-axis CNC grinding ensures consistent cutting edge sharpness and flute geometry.

Anti-Vibration Design

Proprietary flute and neck geometry minimizes chatter and improves stability in long reach machining.

High-Polished Cutting Edges

Prevents built-up edge (BUE) formation, critical for machining aluminum and copper alloys.

Customized Tool Engineering

We offer OEM/ODM customization based on client needs, including special flute designs, coatings, and sizes.

Why Choose Our Carbide End Mills?

Expertise in Carbide Manufacturing: As a dedicated carbide company, we control every step from powder metallurgy to tool grinding.

Global Standards Compliance: Our tools conform to ISO, DIN, and ANSI standards, ensuring compatibility worldwide.

Consistent Quality Assurance: Each tool undergoes rigorous inspection for accuracy, hardness, and coating thickness.

Industry-Focused Solutions: We provide tailored tools for aerospace, automotive, medical, and mold industries.

Conclusion

The Carbide 2-Flute Long Neck Deep Groove Ball Nose End Mill represents the perfect combination of material science, tool design, and precision engineering. Whether you are machining deep cavities in molds, sculpting complex aerospace parts, or creating precision medical implants, this tool ensures high performance, durability, and accuracy.

By choosing our carbide tools, you are investing in superior machining efficiency, reduced costs, and long-term reliability. As a trusted carbide manufacturer, we continue to push innovation forward—helping industries worldwide achieve precision at the highest level.

Previous page

Next page

Use equipment

CNC machining centre

CNC machine tools

Carved machine

Factory Board

Factory Board

Factory Board

Factory Board

Factory Board

Recommended products

FAQ

2025-12-12

Lizhou Indexable U-Drill Series | High-Speed Drilling Solution for Large-Hole U-Drills

The Lizhou U-drill series is suitable for large-hole drilling in a variety of materials, including steel, stainless steel, alloy steel, and titanium alloys. It offers two structural types: square U-drills and peach-shaped U-drills. These drills combine rigidity, centering accuracy, and chip-removal efficiency, enabling multi-process machining that includes drilling, boring, and chamfering. Featuring high-quality carbide inserts and a stable tool body design, this series ensures more efficient batch drilling at lower costs.

2025-12-12

Lizhou Carbide Turning Inserts Series | Cemented Carbide CNC Turning Solutions

The Lizhou carbide turning blade series specializes in CNC turning applications using cemented carbide, covering common machining operations such as external cylindrical turning, end-face turning, roughing, and finishing. We offer diamond-shaped blades, square blades, triangular blades, peach-shaped blades, and peel-off blades, each tailored with specific grades and flute geometries for materials including cast iron, steel, stainless steel, high-hardness steel, and copper and aluminum. These blades help workshops enhance tool life and improve machining stability.

2025-12-12

Lizhou Threaded Blade Series | High-Precision, Stable Thread-Machining Solution

The Lizhou thread cutting blades are made from high-quality cemented carbide materials, combined with advanced coatings and precise tooth profile grinding, enabling them to meet the machining requirements of various thread standards. Whether working with steel, stainless steel, or high-temperature alloys, these blades maintain excellent wear resistance and cutting stability, making them ideal for mass production and thread machining applications that demand high consistency.

2025-12-12

Lizhou Solid Carbide End Mill Series | GX GG BS TS AL Milling Solutions

The Lizhou end-mill series covers a wide range of materials, including steel, stainless steel, quenched and tempered steel, aluminum alloys, and titanium alloys, and corresponds to five major carbide end-mill lines: GX, GG, BS, TS, and AL. Available in flat-end, round-nose, ball-nose, and multi-flute configurations, these end mills are suitable for roughing, finishing, and high-speed machining. Featuring an ultra-fine-grain matrix and comprehensive quality control throughout the entire manufacturing process, these tools deliver more stable tool life and smoother machining performance.