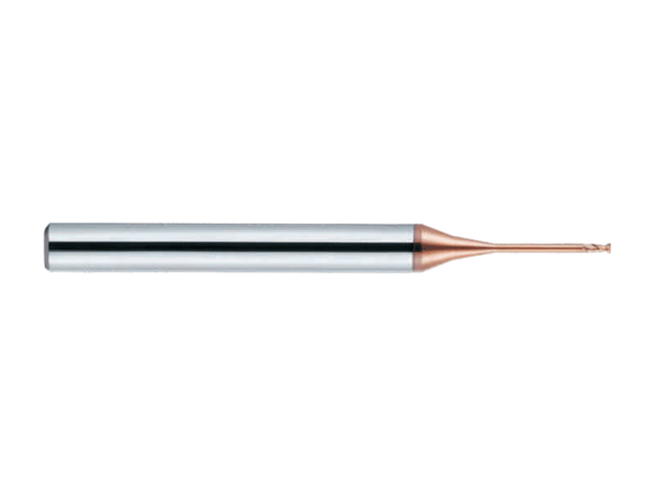

Product

4-Flute Flat End Mill

China Lizhou Hard Alloy Source Factory

Blade count and type: 4 insert flat head

Product model (brand):MS-4E

Suitable for processing materials:Cast iron, steel, stainless steel

Classification :

Carbide End Mill Featured Products

keyword:

lizhou

Carbide 3-Flute Flat End Mill: Comprehensive Guide, Applications, and Advantages

Introduction

In modern machining and precision manufacturing, carbide cutting tools have become the backbone of efficiency, accuracy, and durability. Among the many variants, the Carbide 3-Flute Flat End Mill stands out as a versatile and reliable tool designed for processing a wide range of materials, especially steels, stainless steels, aluminum alloys, titanium, and hardened materials.

As a professional carbide tooling manufacturer, our company specializes in developing high-performance solid carbide tools that combine innovation, precision engineering, and material science to meet the demands of industries such as aerospace, automotive, die and mold, and general machining.

This article provides a detailed introduction to the Carbide 3-Flute Flat End Mill, covering its advantages, usage scenarios, product features, innovative technologies, and best practices for achieving optimal machining performance.

Product detail drawing

1. What is a Carbide 3-Flute Flat End Mill?

1. What is a Carbide 3-Flute Flat End Mill?

A Carbide 3-Flute Flat End Mill is a solid carbide cutting tool designed with three helical cutting edges (flutes) and a flat cutting end. Unlike ball nose end mills, which produce curved surfaces, flat end mills are optimized for machining sharp-edged slots, pockets, contours, and flat-bottomed cavities.

Key characteristics:

Material: Made of fine-grain tungsten carbide with cobalt binder.

Flute count: Three flutes, balancing cutting edge strength and chip evacuation.

Cutting geometry: Flat end with sharp edges for precision milling.

Applications: Roughing, semi-finishing, and finishing of metals and non-metallic materials.

2. Advantages of Carbide 3-Flute Flat End Mill

2.1 Material Advantages of Solid Carbide

High hardness: Carbide tools are harder than HSS (High-Speed Steel), ensuring excellent wear resistance.

Heat resistance: Maintains hardness and cutting edge sharpness at high temperatures.

Longer tool life: Carbide end mills typically last 2–5 times longer than HSS tools.

Dimensional stability: Less tool deflection under heavy cutting loads, ensuring higher accuracy.

2.2 Performance Advantages of 3 Flutes

Optimized balance: Compared with 2-flute mills (good for aluminum) and 4-flute mills (good for steel), the 3-flute design provides a balance between chip clearance and cutting edge strength.

Efficient chip evacuation: Larger flute spaces than 4-flute tools allow smooth chip removal, reducing the risk of tool clogging.

Versatility: Performs well across a variety of materials, including steel and aluminum alloys.

Higher feed rates: More cutting edges engage the material compared with 2-flute mills, improving productivity.

2.3 Cutting Edge Benefits

Flat-bottom machining: Ensures accurate surface finish in pockets, slots, and shoulders.

Reduced chatter: Balanced cutting geometry lowers vibration and ensures stable milling performance.

Excellent surface finish: Capable of achieving high-quality surfaces with fewer secondary finishing operations.

3. Applications of Carbide 3-Flute Flat End Mill

The Carbide 3-Flute Flat End Mill is widely used in industries requiring high precision and efficiency.

3.1 Aerospace Industry

Machining titanium alloys, Inconel, and stainless steel for turbine blades, structural components, and aerospace fasteners.

Ensures high dimensional accuracy for complex geometries.

3.2 Automotive Industry

Milling engine components, transmission parts, molds for automotive plastics, and chassis structures.

Provides efficient material removal for both soft and hardened steels.

3.3 Mold & Die Industry

Tool and die machining for injection molds, stamping dies, and die-casting components.

Excellent for finishing flat surfaces and contour milling.

3.4 General Machining

Suitable for slotting, pocketing, contouring, and side milling.

Works on a variety of materials: carbon steel, stainless steel, aluminum, copper, and plastics.

4. Features of Carbide 3-Flute Flat End Mill

4.1 Design Features

Helical flute design: Enhances chip flow and reduces cutting resistance.

Sharp cutting edges: Achieve smooth and precise cutting.

Flat cutting end: Ideal for accurate depth machining with clean bottoms.

4.2 Coating Options

TiAlN (Titanium Aluminum Nitride): High heat resistance, excellent for stainless steel and hardened steel.

TiCN (Titanium Carbonitride): Lower friction and longer tool life in general steel machining.

DLC (Diamond-Like Carbon): Excellent for aluminum and non-ferrous alloys, reducing built-up edge formation.

4.3 Available Sizes

Diameter range: 1mm to 25mm (customization available).

Shank type: Straight shank, Weldon shank, or customized.

Length: Standard and extended versions for deep cavity milling.

5. Technical Innovations and Patents

Our carbide 3-flute end mills incorporate advanced R&D-driven innovations to deliver superior performance:

Nano-grain carbide substrate: Enhances toughness and resistance to edge chipping.

Advanced coating technologies: PVD and CVD coatings extend tool life by 50–200%.

Optimized helix angle: Reduces cutting forces and prevents vibration during high-speed machining.

Coolant-through design (optional): Internal coolant channels for improved chip evacuation and heat reduction.

Proprietary flute polishing technology: Prevents chip sticking and improves surface finish.

We continuously file patents for flute geometry design and cutting edge preparation to ensure our tools stay at the forefront of machining technology.

6. Best Practices and Usage Guidelines

6.1 Cutting Parameters

For Steel (35–55 HRC):

Cutting speed: 60–120 m/min

Feed rate: 0.03–0.10 mm/tooth

For Stainless Steel:

Cutting speed: 50–100 m/min

Feed rate: 0.02–0.08 mm/tooth

For Aluminum Alloys:

Cutting speed: 150–300 m/min

Feed rate: 0.05–0.20 mm/tooth

6.2 Usage Tips

Always use rigid clamping to prevent tool deflection.

Apply coolant when machining stainless steel or titanium to reduce tool wear.

For aluminum, use air blast or mist lubrication to prevent built-up edge.

Avoid overloading; follow recommended cutting parameters.

6.3 Maintenance Tips

Inspect cutting edges regularly for wear.

Store in a dry, dust-free environment.

Use tool presetters for accurate setup and longer tool life.

7. Why Choose Our Carbide 3-Flute Flat End Mill?

OEM & ODM service: We customize flute geometry, coatings, and dimensions for specific applications.

High precision manufacturing: Tolerances within ±0.005mm.

Cost-effectiveness: Competitive price-performance ratio compared with international brands.

Strict quality control: ISO-certified production with full traceability.

Global export experience: Trusted by clients across Europe, Southeast Asia, Africa, and South America.

Conclusion

The Carbide 3-Flute Flat End Mill is an essential tool for high-efficiency machining, offering superior performance across steels, stainless steels, aluminum, and exotic alloys. With the combined advantages of solid carbide material, optimized 3-flute design, advanced coatings, and precision engineering, it is the ideal solution for manufacturers seeking longer tool life, improved productivity, and consistent machining accuracy.

By integrating our technical innovations, R&D-driven designs, and strict quality standards, we provide carbide end mills that help our customers stay competitive in today’s demanding manufacturing landscape.

Whether you are in aerospace, automotive, mold & die, or general machining, our Carbide 3-Flute Flat End Mills are engineered to deliver efficiency, durability, and precision at every step of your production process.

Previous page

Next page

Use equipment

CNC machining centre

CNC machine tools

Carved machine

Factory Board

Factory Board

Factory Board

Factory Board

Factory Board

Recommended products

FAQ

2025-05-29

The naming conventions for turning inserts generally follow international standards (such as ISO standards). The model number consists of a series of letters and numbers, each character representing different geometric parameters or functional characteristics, such as the naming convention for the TNMG160404R-PV turning insert from Lizhou.

2025-05-26

What types of end mills are there?

Materials can be processed according to different types of end mills, categorized by the types of milling tools, including flat end mills, ball end mills, radius end mills, chamfer end mills, and end mills with chip breakers.

2025-05-23

PCD milling cutter is a polycrystalline diamond (PCD) milling cutter, which has a wide range of applications in the field of machining.

2025-05-08

End mill for machining aluminum materials

Many customers have told us that ordinary end mills frequently stick when machining aluminum, and the accumulation of chips affects the accuracy, so they always change the tools. LIZHOU editor suggests that coated end mills are not recommended for aluminum materials, because some coatings contain aluminum elements. Therefore, it is better to choose uncoated end mills when selecting end mills for machining aluminum materials.