Blog

Customized solutions for carbide cutting blades used in processing aluminum alloys

Pursuing high efficiency, high surface finish, and burr-free machining of aluminum alloys? Are general-purpose blades not up to the task?

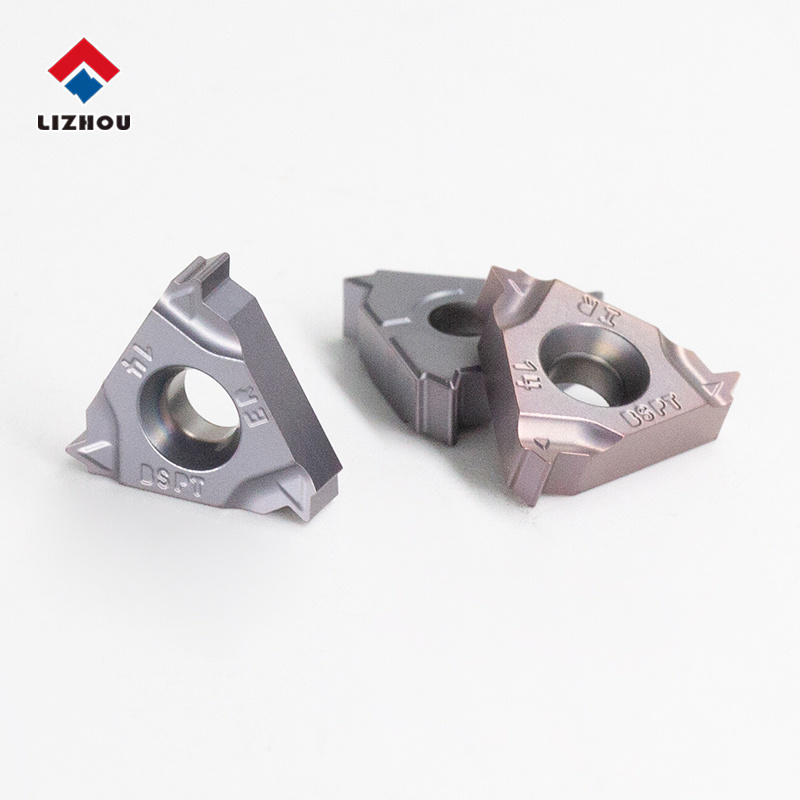

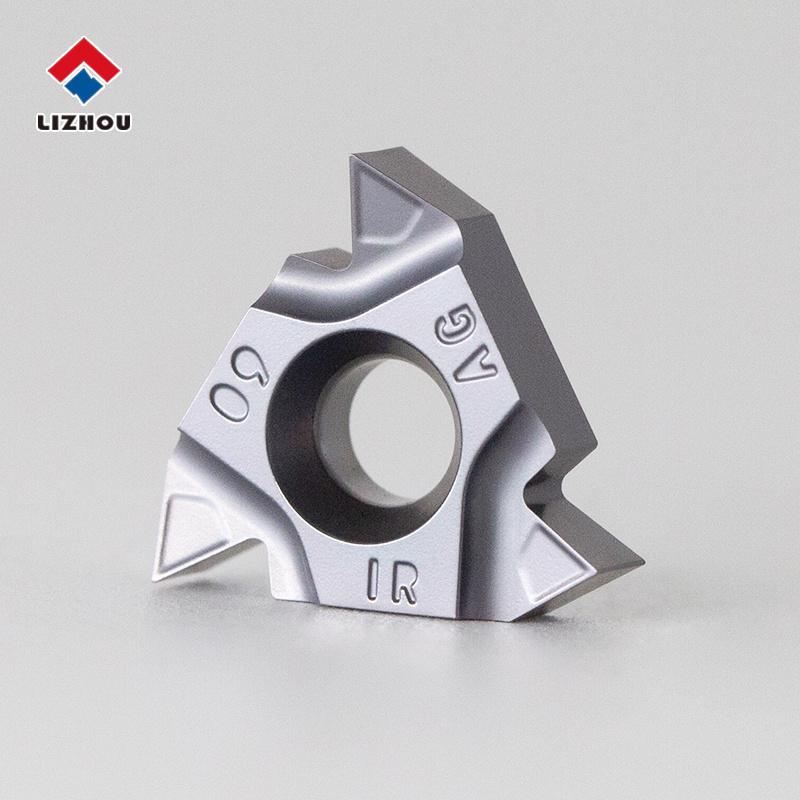

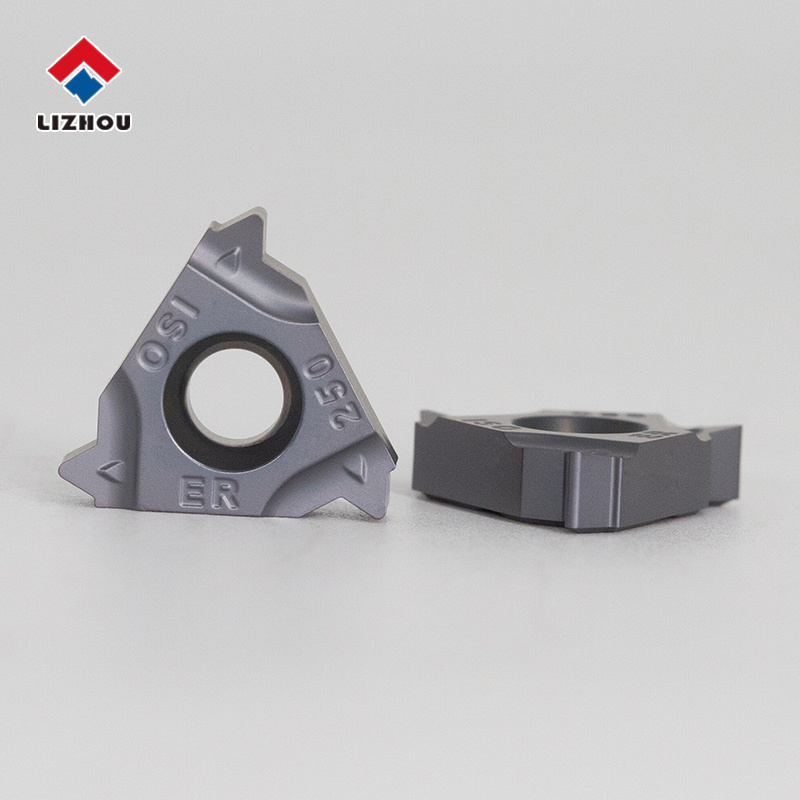

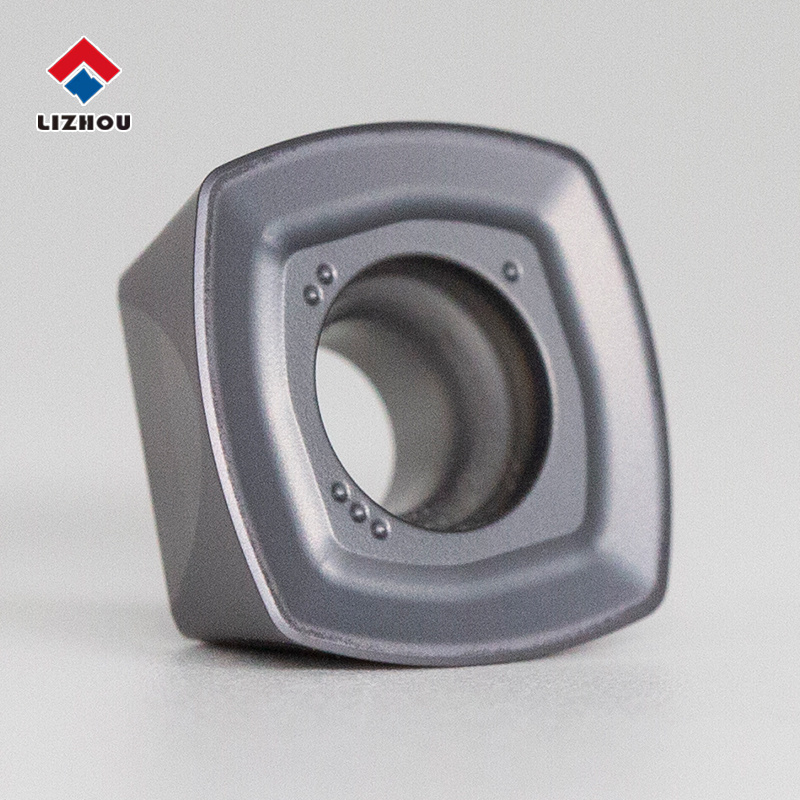

We provide professional cemented carbide turning blades customization services , specifically designed with optimized geometry for your specific aluminum alloy grade, workpiece shape, and machining requirements (roughing, finishing, grooving, threading)

Cemented carbide turning blades: The core tools driving modern manufacturing

Automotive Manufacturing: High-efficiency turning of engine blocks, transmission gear shafts, wheel hubs, and steering knuckles.

Aerospace: Precision machining of aircraft landing gear, engine components, and spacecraft structural parts (also applicable to titanium alloys and high-temperature alloys).

Mold Manufacturing: Precision machining of mold cores, cavities, guide posts, and bushings, ensuring high precision and surface finish.

General Machinery: Machining pump and valve housings, hydraulic components, transmission shafts, bearing seats, and various other rotary parts.

Energy Equipment: Turning turbine rotors, valves, and pipe fittings.

Superior Performance Stemming from Solid Quality: The Unique Advantages of Lizhou Customized Blades

Precise Matching: Geometric parameters and coatings are tailored to your specific working conditions , resulting in performance far exceeding that of general-purpose blades.

Ultimate Efficiency: Optimized design allows for higher cutting parameters (cutting speed Vc , feed rate f ), significantly reducing unit processing time.

Exceptional Durability: Selected substrate and enhanced coating technology (such as nano-composite coatings) provide superior wear resistance and increased tool life 30% and more.

Perfect Surface Finish: Sharp cutting edges combined with a dedicated chip breaker design ensure high surface finish and burr-free requirements in aluminum alloy machining.

Reliable and Stable: Strict process control ensures consistent performance of each blade, reducing tool changes and improving the stability of automated production lines.

Frequently Asked Questions on Turning Blade Applications (FAQ)

Q : Blade chipping prematurely?

A : Check clamping rigidity (ensure the tool holder is secure and free from vibration), verify that the cutting parameters are not too high (especially the feed rate), and confirm that the edge strength (blunting amount / burr) is suitable for the current working conditions (e.g., intermittent cutting requires a stronger cutting edge), and check for hard spots or sand inclusions in the workpiece.

Q : Severe tool sticking when machining aluminum alloys?

A : Prioritize the use of sharp cutting edge designs (large rake angle) and low-friction coatings (such as diamond coatings or special PVD coatings), ensure sufficient cooling (recommend high-quality emulsion or oil mist cooling), and appropriately increase the cutting speed.

Q : Chatter marks appear on the workpiece surface?

A : Increase the rigidity of the entire process system (check the machine tool, tool holder, and tool shank), appropriately reduce the cutting parameters (especially the depth of cut), select a positive rake angle and sharp cutting edge blade, and confirm that the nose radius is not too large.

Q : Chips wrap around the workpiece or tool?

A : Optimizing the chip breaker design is key! Provide your cutting parameters ( ap, f ) and material information, and we will customize a high-efficiency chip breaker type for you (such as wide V -shaped, raised platform type), and check whether the coolant effectively removes the chips.

Q : How to choose the most economical blade?

A : “ Cheapest ” does not equal “ Most economical ” 。Consider the comprehensive machining efficiency (unit cost), tool life, quality stability, and downtime for tool changes. Custom blades often achieve better overall economic benefits by improving performance and lifespan. 。

Stop letting general-purpose blades limit your production potential. With our professional customization capabilities, strong supply chain, and excellent price-performance ratio, we help you achieve a qualitative leap in the turning of aluminum alloys and other materials.

Recommended products