Product

Threaded insert- R type

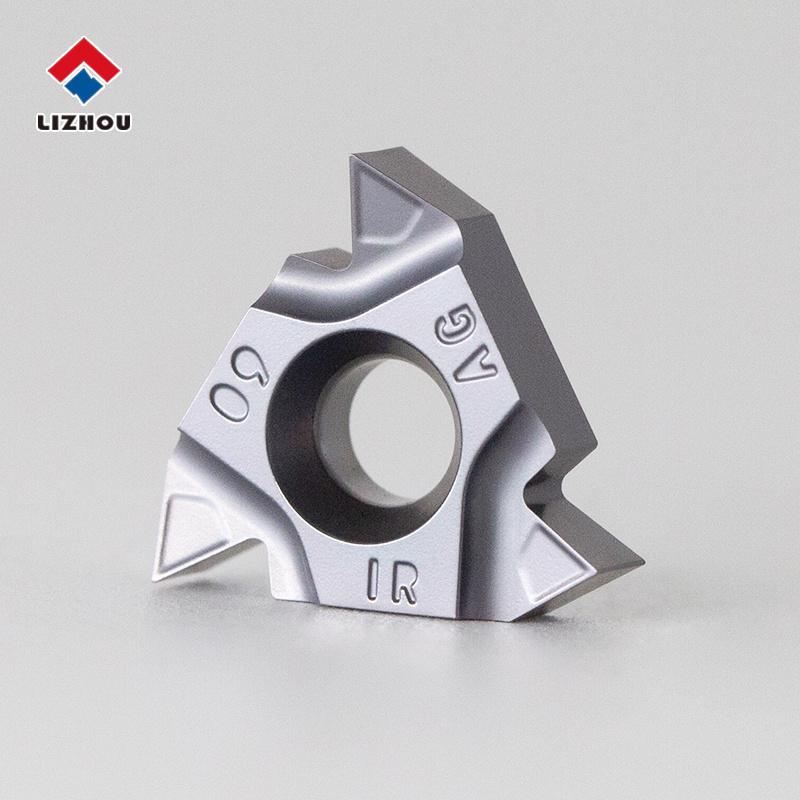

China Lizhou Hard Alloy Source Factory

Product Name:Therading inserts

Thread Type:External thread

Coating : PVD

Classification :

Threading insert

keyword:

lizhou

Threaded Insert – R Type: Precision Carbide Threading Solutions from Lizhou

Introduction

In modern machining, precision threading remains one of the most critical operations, determining the strength, compatibility, and sealing performance of assembled components. For industries ranging from automotive and aerospace to oil & gas, energy, and general manufacturing, the reliability of threaded joints cannot be compromised. To address these challenges, Lizhou, a professional carbide manufacturer, offers the Threaded Insert – R Type.

This product is part of our advanced carbide threading insert portfolio, engineered for efficiency, accuracy, and durability. It combines the inherent advantages of cemented carbide with specialized geometry (R type) to achieve superior threading results across a wide variety of materials.

This article provides a comprehensive introduction to the Threaded Insert – R Type, covering its carbide performance advantages, design parameters, geometry meaning, applications, role, features, safety considerations, and technical innovations—all aligned with global machining standards and Google SEO intent.

Type | External thread | Basic dimensions (mm) | PVD | ||||

Pitch | I.C | S | D | LPP203 | LMP203 | ||

16ER1.00ISO | 1.0 | 9.525 | 3.52 | 4.0 |

| √ | |

16ER1.50ISO | 1.5 | 9.525 | 3.52 | 4.0 |

| √ | |

16ER2.00ISO | 2.0 | 9.525 | 3.52 | 4.0 |

| √ | |

16ER2.50ISO | 2.5 | 9.525 | 3.52 | 4.0 |

| √ | |

16ER3.00ISO | 3.0 | 9.525 | 3.52 | 4.0 |

| √ | |

Type | Internal thread | Basic dimensions (mm) | PVD | ||||

Pitch | I.C | S | D | LPP203 | LMP203 | ||

16IR1.00ISO | 1.0 | 9.525 | 3.52 | 4.0 |

| √ | |

16IR1.50ISO | 1.5 | 9.525 | 3.52 | 4.0 |

| √ | |

16IR2.00ISO | 2.0 | 9.525 | 3.52 | 4.0 |

| √ | |

16IR2.50ISO | 2.5 | 9.525 | 3.52 | 4.0 |

| √ | |

16IR3.00ISO | 3.0 | 9.525 | 3.52 | 4.0 |

| √ | |

1. Advantages of Carbide Threading Inserts

At the core of Lizhou’s threaded inserts is cemented carbide, a material renowned for its exceptional hardness, wear resistance, and thermal stability. Compared with HSS (High-Speed Steel) or traditional tooling, carbide threading inserts deliver:

Extended Tool Life – The high hardness of carbide ensures resistance against flank wear and crater wear, even in high-volume production.

High Cutting Speed Compatibility – Carbide inserts allow higher cutting speeds and feeds, reducing cycle time.

Superior Heat Resistance – Cemented carbide maintains its strength at elevated temperatures, crucial for threading difficult-to-machine alloys.

Dimensional Stability – Consistent thread accuracy is maintained over long production runs.

Versatility Across Materials – Effective on steels, stainless steels, cast iron, non-ferrous metals, and superalloys.

These properties make carbide threading inserts indispensable in industries where precision and productivity must coexist.

External thread

2. Decoding the “R Type” Designation

Threading inserts are classified according to geometry codes, which determine cutting edge profile, chip evacuation, and application suitability.

“R Type” generally refers to a general-purpose round-shaped or radius-modified insert geometry optimized for threading. It emphasizes strength of the cutting edge, enabling:

Reduced risk of chipping in tough materials.

Stable performance in interrupted cuts.

Balanced cutting forces for smooth thread formation.

In Lizhou’s catalog, R Type represents inserts designed with reinforced cutting edge radii, making them ideal for machining materials where tool breakage risk is higher, such as stainless steel or titanium alloys.

3. Dimensional Parameters and Standards

Threaded Insert – R Type follows ISO, ANSI, and custom threading standards to ensure compatibility with global threading applications. The parameters typically include:

IC (Inscribed Circle): Defines the insert size, e.g., 9.525 mm or 12.7 mm.

S (Thickness): Insert thickness for rigidity and stability.

D (Cutting Edge Length): Determines maximum thread depth.

Pitch Compatibility: Depending on insert type, can cover fine, medium, and coarse pitches.

Thread Angle (α°): Common thread profiles include 60° (metric/UN) and 55° (Whitworth/BSP).

Each R Type insert is manufactured with tight tolerances, ensuring thread accuracy and interchangeability with leading CNC toolholders.

4. Application Scenarios

Lizhou’s Threaded Insert – R Type is engineered for a broad spectrum of applications:

Oil & Gas – Threading of pipes, couplings, and connectors requiring leak-proof joints.

Automotive – Precision fasteners, engine parts, and transmission components.

Aerospace – Titanium and nickel-based alloys threaded with high reliability.

General Machinery – Shafts, bolts, nuts, and custom threaded parts.

Energy Sector – Threading turbine housings, valves, and large-diameter components.

Whether for internal threads (IR type) or external threads (ER type), Lizhou’s R Type insert ensures reliable performance in both small-batch and mass production.

5. Functional Role and Benefits

The Threaded Insert – R Type serves a crucial role in modern CNC lathes and turning centers:

Thread Cutting Precision – Produces consistent profiles conforming to ISO/ANSI standards.

Reduced Downtime – Quick indexing with multi-corner inserts reduces machine stoppages.

Surface Finish Optimization – R geometry ensures smoother thread flanks and crests.

Chip Control – Designed to evacuate chips efficiently, preventing damage to threads.

Cost Efficiency – Longer tool life reduces insert consumption and overall cost per thread.

6. Key Features

High-Quality Carbide Substrate – Optimized for toughness and wear resistance.

Advanced PVD/CVD Coatings – TiAlN, AlTiN, or multilayer coatings enhance heat resistance.

R Geometry Reinforcement – Prevents micro-chipping, ensures durability in hard alloys.

Multi-Corner Design – Maximizes usable cutting edges per insert.

Compatibility – Fits standard toolholders for threading, reducing investment costs.

7. Precautions and Best Practices

To maximize performance of Threaded Insert – R Type, consider the following:

Correct Holder and Clamping – Use rigid, vibration-free setups.

Appropriate Cutting Parameters – Match cutting speed and feed to material hardness.

Coolant Use – Employ high-pressure coolant when threading stainless steel or titanium to reduce heat.

Threading Depth per Pass – Avoid excessive depth per pass; use multiple shallow cuts for accuracy.

Insert Inspection – Monitor for flank wear, crater wear, and edge chipping.

8. Technological Innovation and Patents

Lizhou integrates R&D-driven improvements into its threaded insert production:

Nanostructured Coatings – Proprietary multilayer coating for extended tool life.

Chipbreaker Design – Optimized micro-geometry reduces cutting forces.

Carbide Grain Control – Fine-grain carbide enhances toughness without sacrificing hardness.

Patent-Protected Edge Radii – Specialized R-type radii geometry improves edge stability.

Sustainability – Inserts manufactured with eco-friendly sintering and recycling programs.

These innovations ensure that Lizhou’s products are competitive with global leaders in cutting tool technology.

9. Why Choose Lizhou?

As a professional carbide manufacturer, Lizhou provides more than just inserts—we deliver solutions:

Customization – Inserts tailored to customer-specific threading needs.

Consistency – Strict quality control in every production batch.

Global Standards – Compliance with ISO, ANSI, API, and DIN thread requirements.

After-Sales Support – Technical guidance and troubleshooting for customers worldwide.

Conclusion

The Threaded Insert – R Type by Lizhou embodies the perfect balance of material science, precision engineering, and application-driven design. By combining the robustness of carbide substrates, advanced R geometry reinforcement, and innovative coatings, it addresses the needs of industries where reliable and accurate threading is essential.

From oil & gas pipes to aerospace fasteners, Lizhou’s R Type threaded insert delivers performance, durability, and cost efficiency—backed by a manufacturer committed to continuous innovation and global customer support.

For companies seeking precision, reliability, and productivity in threading operations, the Threaded Insert – R Type is the solution of choice.

Previous page

Next page

Use equipment

CNC machining centre

CNC machine tools

Carved machine

Factory Board

Factory Board

Factory Board

Factory Board

Factory Board

Recommended products

FAQ

2025-05-29

The naming conventions for turning inserts generally follow international standards (such as ISO standards). The model number consists of a series of letters and numbers, each character representing different geometric parameters or functional characteristics, such as the naming convention for the TNMG160404R-PV turning insert from Lizhou.

2025-05-26

What types of end mills are there?

Materials can be processed according to different types of end mills, categorized by the types of milling tools, including flat end mills, ball end mills, radius end mills, chamfer end mills, and end mills with chip breakers.

2025-05-23

PCD milling cutter is a polycrystalline diamond (PCD) milling cutter, which has a wide range of applications in the field of machining.

2025-05-08

End mill for machining aluminum materials

Many customers have told us that ordinary end mills frequently stick when machining aluminum, and the accumulation of chips affects the accuracy, so they always change the tools. LIZHOU editor suggests that coated end mills are not recommended for aluminum materials, because some coatings contain aluminum elements. Therefore, it is better to choose uncoated end mills when selecting end mills for machining aluminum materials.