Blog

FAQ

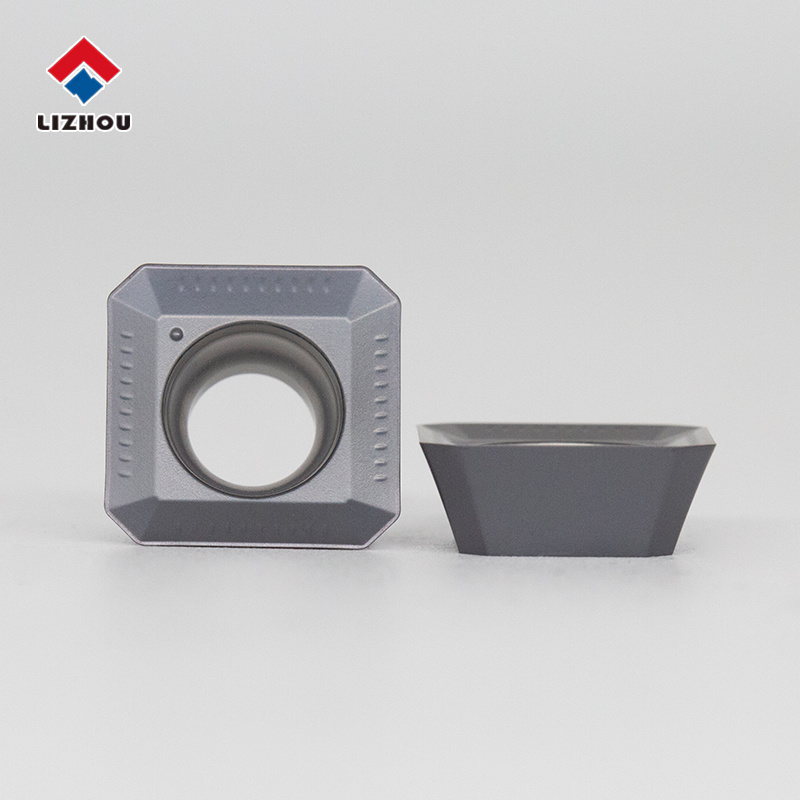

SNMU1305 Square Milling Insert | Double-Sided 8-Flute Heavy-Feed Milling

SNMU1305 Square milling inserts—stable milling inserts designed for heavy-duty cutting.

At Milling insert During machining, there is a particular type of working condition that is especially demanding—large cutting depth, high feed rate, hard materials, and long machining times.

In this situation, if the blade lacks sufficient rigidity, it can easily lead to chatter, chipping, and even compromise the stability of the machine tool. For this type of heavy-load machining scenario, SNMU The series of square milling inserts has always been a highly regarded model in workshops.

SNMU1305 This is one of our practical milling blades, specifically designed for gravity milling and emphasizing stability and durability.

Square-shaped design, double-sided usability—truly durable and cost-effective.

SNMU1305 Adopting a standard square blade design, each blade features... 4 A cutting edge.

More importantly, it features a double-sided design that allows either side to be used—meaning:

One blade, in total 8 Single cutting edge: Replace the blade only after the entire cutting edge has been fully worn out—this significantly reduces the cost per blade.

For users who require extensive milling and long, continuous machining operations, this structural design offers very obvious economic advantages.

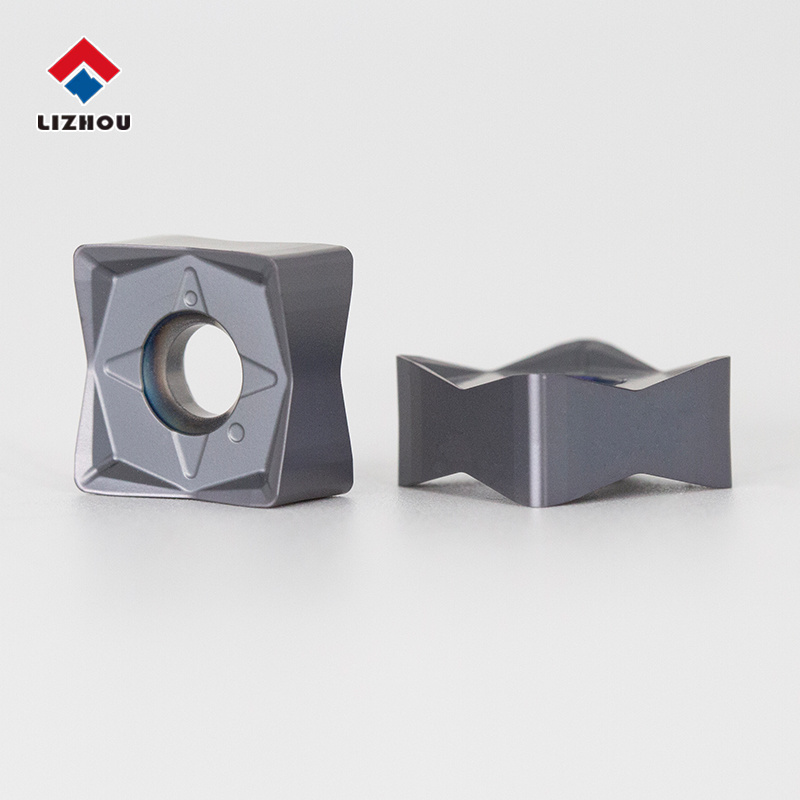

0 °Back rake design, high rigidity, specially designed for heavy cutting.

SNMU1305 Adopted 0 ° Back angle ( N Type) structure.

The biggest feature of this design is that the blade is thick and highly rigid.

In actual machining, the intuitive experience is that the cutting blade is less likely to chip, has strong impact resistance, remains stable even when cutting deeply, and the cutting process is less prone to “vibration.”

Therefore, this blade is ideally suited for heavy-duty machining operations such as gravity milling and high-feed milling.

Optimized chip-breaking groove, smooth chip evacuation, and less likelihood of chip accumulation.

During deep, heavy-duty milling, smooth chip removal is crucial.

SNMU1305 The chip-breaker groove structure has been optimized to make chips easier to break and discharge.

1. Chips don't easily get tangled.

2. Reduce the formation of built-up edges.

3. The blade edge is cleaner.

4. The processing procedure is more stable.

This is especially important when machining steel parts and stainless steel.

Even with deep cuts, the tool can be fed steadily, resulting in higher machining efficiency.

SNMU1305 This blade type is specifically designed for “heavy cutting.” In actual use:

Can withstand larger cutting depths.

The cutting process is smooth.

The machine tool load is more uniform.

More material removed per unit time.

If your machining goal is rapid planar milling and fast stock removal, these blades are more suitable than light-cutting models.

Applicable Material Range

SNMU1305 Commonly used for milling operations on the following materials: steel parts, stainless steel.

It is particularly suitable for applications involving materials with high strength and large machining allowances.

SNMU1305 What does it actually represent?

Here's the explanation broken down in the simplest possible way:

S : Indicates that the blade shape is square.

N : Indicates 0 ° Back rake angle (negative geometry, high rigidity)

M : Indicates manufacturing tolerance grade

You Indicates blade type and application method.

13 : Indicates the blade's size specification (edge length grade)

05 Indicates the blade thickness and dimensions related to the cutting edge.

EN-GM : Indicates the specific chip-breaker groove configuration.

LMP206 Indicates the applicable material and coating direction, suitable for machining steel and stainless steel parts.

By understanding these points, you’ll be able to more quickly determine whether this blade is suitable for your machining conditions.

What processing scenarios is it suitable for?

SNMU1305 Particularly suitable for: large-depth milling, heavy-load machining, face milling, and applications where stability is the top priority.

If you’re more concerned about stability, durability, and whether it can handle cutting, rather than pursuing extreme precision in finishing, this blade will be a better fit.

Recommended products