Blog

FAQ

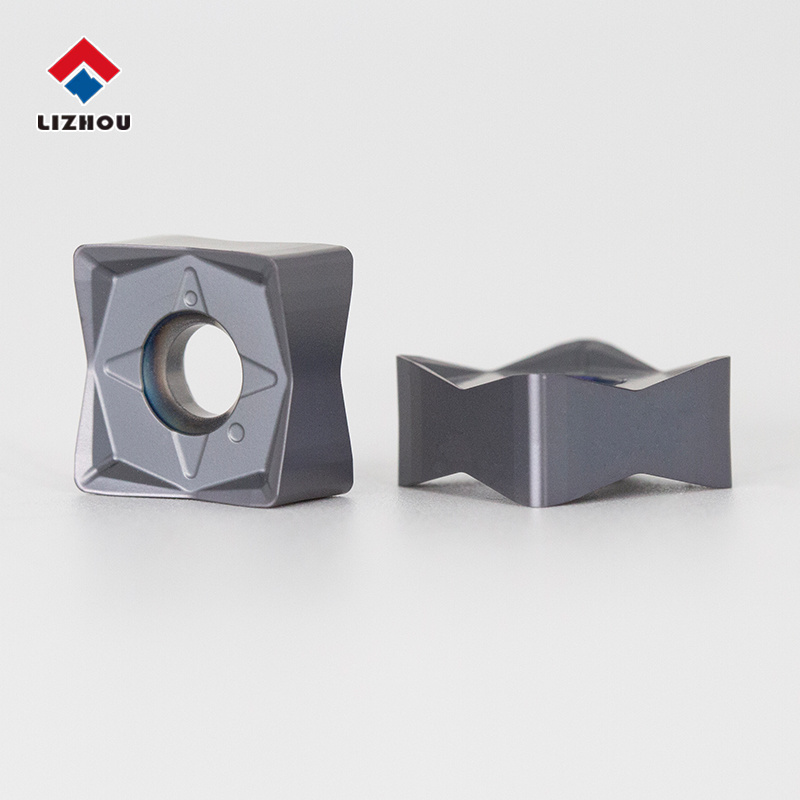

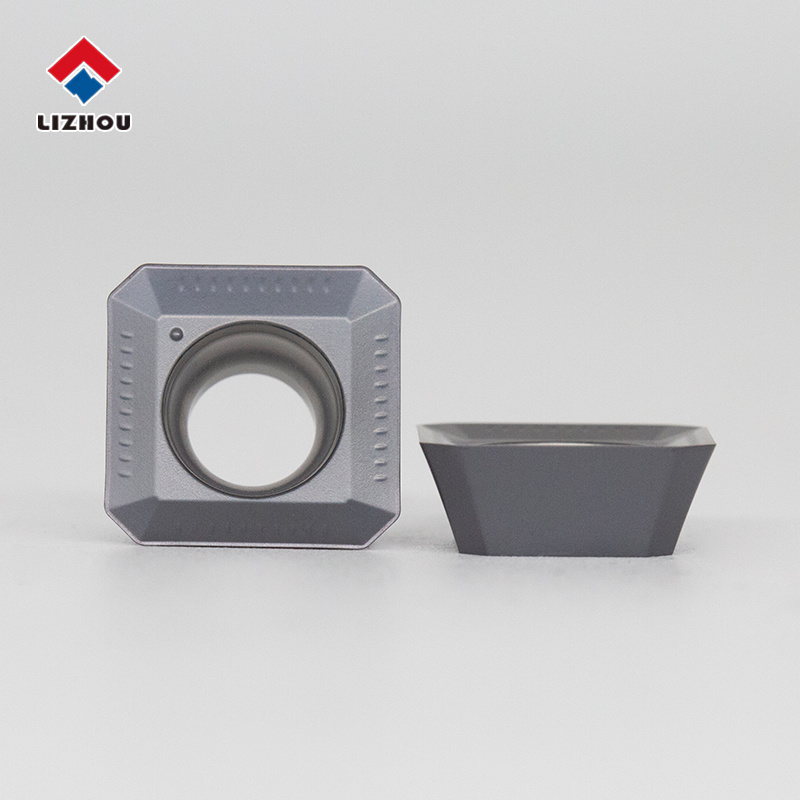

SEKT1204 Square Milling Cutter Inserts | Ideal for Machining Steel and Stainless Steel—Durable and Wear-Resistant

SEKT1204 Square milling insert—a versatile, durable, and hassle-free milling insert.

At Milling insert During processing, what many people really care about boils down to just three key points: Is the blade cutting smoothly? Is it durable? And is the cost high?

If a milling cutter blade keeps chipping, has an unsightly surface finish, and needs to be replaced frequently, no matter how impressive the parameters may seem, it’ll never be hassle-free to use.

SEKT1204 The square milling insert is a model that’s relatively “easy to use” in actual machining operations, and many users who process steel parts and stainless steel tend to stick with it for the long term.

A single knife, there is. 4 A sharper edge, lasts longer.

SEKT1204 It is a indexable milling insert, and one insert has... 4 A single cutting edge.

Simply put: Once you’ve sharpened it here, you can keep turning it and it’ll still be usable; a single blade can last several uses, requiring fewer blade changes and lowering the cost per use. This is especially noticeable when processing in large batches.

Cutting is smooth and light, and doesn't put stress on the machine tool.

This blade features 20 ° The back rake angle is designed to minimize cutting resistance, making the tool feel smooth and effortless during operation. It’s less likely to cause chip buildup, places fewer demands on the machine tool, and is particularly well-suited for semi-finishing steel and stainless steel parts—offering both high speed and excellent stability.

The blade is sharp, and the surface feels pleasant to the touch.

Many people using milling inserts are most concerned about surface roughening and chaotic tool marks.

SEKT1204 It performs quite well in this regard: the blade is relatively sharp, the cut surface is fairly smooth, and the finish is easy to control.

For workpieces that will undergo further processing later, this makes it easy to proceed to the next step.

It’s not easy to break, so you can feel confident when using it. During milling, there’ll always be some degree of impact.

SEKT1204 The selected tungsten carbide matrix is relatively robust, and coupled with an appropriate coating, it offers excellent wear resistance, is less prone to sudden chipping, and ensures stable performance during continuous machining.

No need to keep staring at the tool change—work feels more reliable and steady.

A single knife can handle quite a few tasks.

This square milling cutter blade has a wide range of applications and is versatile:

Planar milling: Fast and stable surface finishing.

Square-shoulder milling: Clean right-angle steps

Contour milling: The contour transition is relatively smooth.

It’s perfect for users who want “one knife to do more things.”

How is it different from other milling inserts?

Let me briefly explain the difference:

The blade is more robust than the light-cutting one.

The blade with higher feed rate is better for surface control.

Doesn't pursue extreme speed, but is stable and easy to use.

It’s the kind that’s not flashy but reliable.

Who is it suitable for?

SEKT1204 Particularly suitable for: users who process steel parts, stainless steel, perform semi-finishing operations, engage in mass production, and prefer fewer tool changes and less maintenance.

If you’re looking for a milling cutter blade that’s easy to use, reliable, and cost-effective, this is a solid choice.

SEKT1204 The square milling insert isn't one of those products that boasts exaggerated specs, but in actual machining, it’s reliable, durable, and hassle-free to use.

Lizhou devotes more attention to the blade’s materials and stability precisely so that you’ll encounter fewer problems and produce more work during machining.

Recommended products