Product

HNMU face milling cutter

China Lizhou Hard Alloy Source Factory

Product Name: face milling cutter

Coating : CVD

Material:Tungsten steel

Classification :

Milling insert

keyword:

lizhou

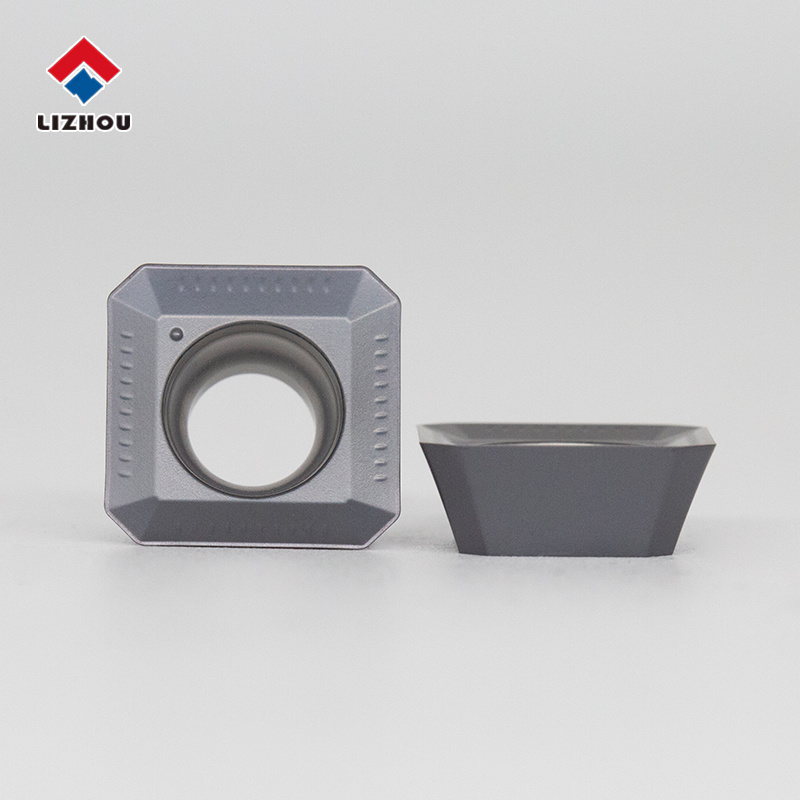

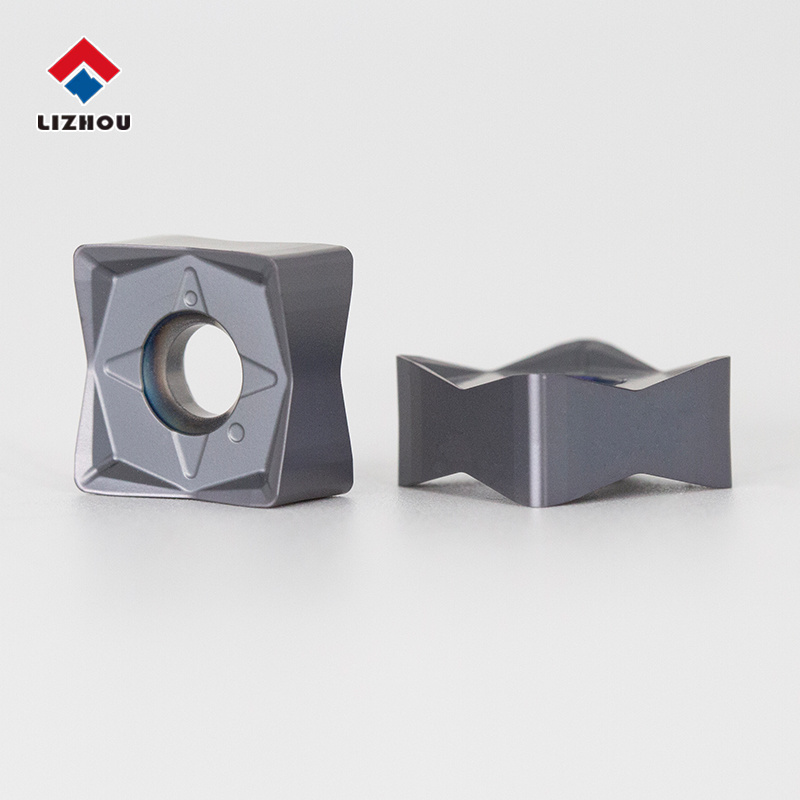

HNMU090612-PM Carbide Milling Insert: Comprehensive Product Introduction

Introduction

In the field of modern machining, precision, stability, and cost-effectiveness are the key factors that determine production efficiency. As industries such as aerospace, automotive, die and mold, and heavy machinery demand higher-quality cutting tools, advanced carbide inserts have become the backbone of metalworking. Among the many options available in the market, the HNMU090612-PM milling insert stands out as a versatile and high-performance solution.

Manufactured with premium-grade tungsten carbide and optimized through cutting-edge technology, this insert is designed to deliver exceptional wear resistance, toughness, and long service life. It is widely used for roughing and semi-finishing applications in steel, stainless steel, cast iron, and other challenging materials.

This article provides a detailed overview of the HNMU090612-PM insert, covering its advantages, performance analysis, design parameters, application scenarios, features, precautions, and technical innovations—making it an ideal reference for engineers, tool buyers, and machining professionals.

1. Advantages of Carbide Milling Inserts

Carbide inserts are preferred over traditional high-speed steel (HSS) tools for multiple reasons. The HNMU090612-PM insert embodies these advantages:

Superior Hardness and Wear Resistance

The insert is produced from fine-grain tungsten carbide, ensuring hardness levels above 90 HRA.

It resists abrasive wear even under high cutting speeds, maintaining sharp edges longer.

Excellent Heat Resistance

Carbide material withstands cutting temperatures exceeding 800°C, reducing tool deformation.

Coatings such as TiAlN or AlTiN enhance thermal stability.

High Productivity

The optimized PM (Positive Medium) geometry allows efficient chip evacuation, reducing cutting forces.

Higher feeds and speeds can be achieved without compromising surface quality.

Longer Tool Life

Compared with conventional inserts, the HNMU090612-PM lasts longer due to improved edge strength and wear resistance.

Versatility in Materials

Suitable for machining carbon steel, alloy steel, stainless steel, cast iron, and even hardened steels with the right grade.

2. Decoding the Insert Code: HNMU090612-PM

Each character in the product code provides valuable information about its design:

H → Insert shape (Hexagonal or special geometry, providing multi-edge usability).

N → Relief angle (0° relief, typically for heavy-duty milling with maximum edge support).

M → Tolerance class (Medium tolerance, ensuring interchangeability and cost balance).

U → Insert type (Special configuration suitable for milling applications).

09 → Insert size indicator (approximate inscribed circle in mm).

06 → Thickness (6 mm insert thickness for robust cutting stability).

12 → Cutting edge length (12 mm, suitable for medium to large engagement).

PM → Chipbreaker and geometry designation.

P: Designed for steel applications.

M: Medium cutting conditions (balanced between roughing and finishing).

Thus, the HNMU090612-PM is a hexagonal carbide insert, 9 mm IC, 6 mm thick, 12 mm edge length, with a steel-optimized medium geometry—perfect for versatile milling tasks.

3. Performance Analysis

The performance of the HNMU090612-PM insert can be evaluated across key machining parameters:

3.1 Cutting Efficiency

The sharp PM geometry reduces cutting forces, enabling higher feed rates.

Ensures smooth cutting with lower spindle load, prolonging machine life.

3.2 Surface Finish

Optimized edge preparation minimizes vibration and chatter.

Achieves surface roughness Ra 1.6–3.2 µm in semi-finishing operations.

3.3 Tool Life

Edge strength prevents premature breakage under interrupted cuts.

Coating layer resists built-up edge (BUE) formation, extending service life.

3.4 Chip Control

The PM chipbreaker is engineered for stable chip evacuation.

Reduces risks of chip jamming in high-volume machining.

3.5 Material Adaptability

Steel (P group): Excellent wear resistance at high speeds.

Stainless steel (M group): Maintains edge sharpness, reducing work hardening.

Cast iron (K group): Performs well under continuous cutting.

4. Application Scenarios

The HNMU090612-PM insert finds extensive use across industries:

General Milling of Steel Components

Automotive engine blocks, shafts, gears, and frames.

Die and Mold Industry

Roughing large cavities and semi-finishing precision surfaces.

Aerospace Machining

High-strength alloy steels and structural parts requiring stability.

Heavy Machinery Manufacturing

Components like housings, plates, and large steel parts.

Batch Production Environments

Consistent performance in CNC machining centers and conventional milling.

5. Key Features and Benefits

Multi-edge usability: Hexagonal geometry provides multiple cutting edges per insert, maximizing cost efficiency.

Stable clamping: Secure insert pocket design ensures rigidity during high-feed milling.

Optimized chipbreaker: PM geometry balances sharpness and toughness, reducing vibration.

Coating technology: TiAlN/AlTiN coatings enhance oxidation resistance.

Flexibility: Effective in roughing and semi-finishing, minimizing tool changes.

6. Precautions in Use

To ensure maximum performance and safety:

Correct Cutting Parameters

Recommended cutting speed: 150–280 m/min for steel, lower for stainless steel.

Feed per tooth: 0.1–0.25 mm depending on application.

Toolholder Compatibility

Use matching cutter bodies designed for HNMU inserts.

Ensure correct torque when tightening screws.

Coolant Application

Apply coolant for stainless steel and high-temp alloys to prevent thermal cracks.

Dry cutting is acceptable for cast iron.

Edge Usage Monitoring

Rotate insert edges systematically to maximize tool life.

Avoid running with dull edges to prevent damage to the cutter body.

Workpiece Setup

Ensure rigid clamping to avoid vibration-induced chipping.

7. Technical and Patent Innovations

The HNMU090612-PM benefits from several modern innovations in carbide tool design:

Advanced Powder Metallurgy

Uniform grain size improves toughness and reduces micro-cracks.

Nano-coating Technology

Coatings with nanolayer structures enhance wear and oxidation resistance.

Optimized Edge Preparation

Precision honing minimizes initial wear and increases insert stability.

Patent-Protected Chipbreaker Design

PM geometry balances chip curling and evacuation, enhancing productivity.

Environmentally Friendly Production

Advanced sintering techniques reduce carbon footprint while improving material density.

8. Why Choose HNMU090612-PM from Our Company?

As a professional carbide insert manufacturer, our strengths include:

Complete Product Range: Supporting a wide array of milling applications with inserts like APKT, RDMW, RPMW, and BLMP.

OEM & Customization: Ability to design inserts tailored to customer drawings or special machining requirements.

Strict Quality Control: From powder preparation to final inspection, ensuring consistency.

Competitive Pricing: Direct factory supply reduces costs for customers.

Global Market Support: Serving clients in automotive, aerospace, mold-making, and heavy industries worldwide.

Conclusion

The HNMU090612-PM carbide milling insert represents the perfect balance between strength, toughness, and cutting efficiency. With its multi-edge hexagonal design, optimized PM chipbreaker, premium carbide material, and advanced coating technology, it ensures high productivity and cost-effectiveness for manufacturers.

Whether you are machining steel, stainless steel, or cast iron, this insert delivers outstanding performance in roughing and semi-finishing applications. Backed by technical innovations and reliable quality control from our company, the HNMU090612-PM is the ideal solution for precision machining in today’s competitive industrial environment.

Previous page

Next page

Use equipment

CNC machining centre

CNC machine tools

Carved machine

Factory Board

Factory Board

Factory Board

Factory Board

Factory Board

Recommended products

FAQ

2025-05-29

The naming conventions for turning inserts generally follow international standards (such as ISO standards). The model number consists of a series of letters and numbers, each character representing different geometric parameters or functional characteristics, such as the naming convention for the TNMG160404R-PV turning insert from Lizhou.

2025-05-26

What types of end mills are there?

Materials can be processed according to different types of end mills, categorized by the types of milling tools, including flat end mills, ball end mills, radius end mills, chamfer end mills, and end mills with chip breakers.

2025-05-23

PCD milling cutter is a polycrystalline diamond (PCD) milling cutter, which has a wide range of applications in the field of machining.

2025-05-08

End mill for machining aluminum materials

Many customers have told us that ordinary end mills frequently stick when machining aluminum, and the accumulation of chips affects the accuracy, so they always change the tools. LIZHOU editor suggests that coated end mills are not recommended for aluminum materials, because some coatings contain aluminum elements. Therefore, it is better to choose uncoated end mills when selecting end mills for machining aluminum materials.