Blog

FAQ

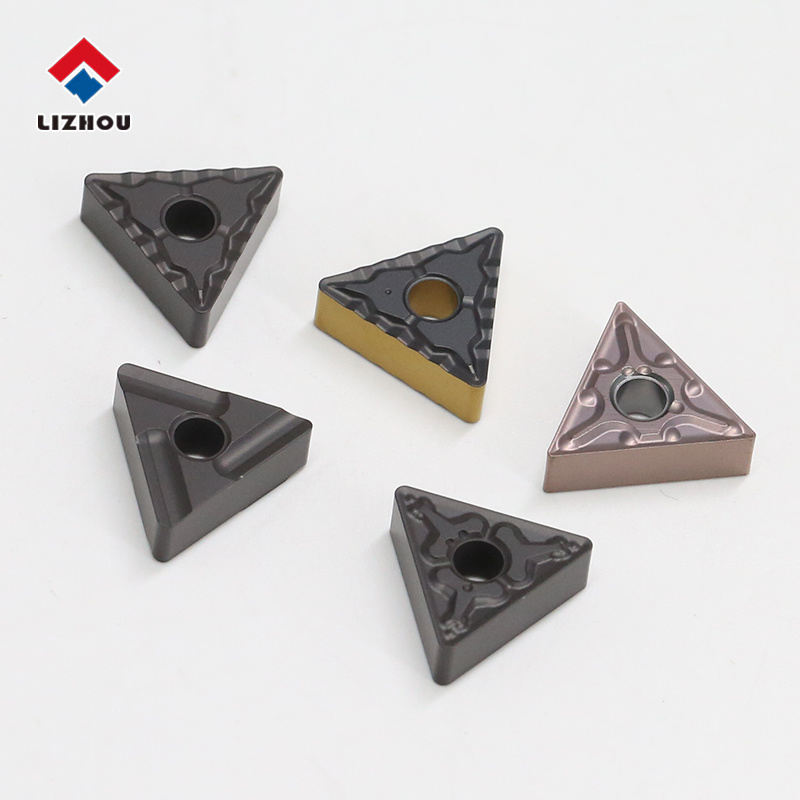

TNMG / TCMT Turning Inserts | General-Purpose CNC Turning

TNMG / TCMT Triangular turning inserts—a practical choice with strong versatility and high cost performance.

In modern machining, many processing problems are not caused by the machine tool or the program itself, but rather by the inappropriate selection of cutting inserts. Particularly in conventional turning operations such as external cylindrical turning, end-face turning, and step turning, if the cutting inserts lack sufficient versatility and have unstable tool life, tool changes will occur frequently, disrupting the machining rhythm.

Triangular turning insert TNMG and TCMT This type of insert is specifically designed for everyday, high-frequency turning applications and is considered a “standard model” in many workshops.

1. Why triangular carbide inserts have consistently been widely used.

The most distinctive feature of triangular carbide inserts is their three-sided cutting edge design.

In practical use, this means:

One blade has 3 Each cutting edge is usable.

After one cutting edge wears out, it can be repositioned for continued use.

The blade has a longer overall lifespan.

The cost per unit is lower.

Compared to single-blade or double-blade blades, triangular blades offer a significantly better value for money—this is precisely why... TNMG 、 TCMT An important reason why it has been widely used all along.

II. 60 °Equiangular structure—universal and easy to use.

TNMG / TCMT Adopted 60 ° Equiangular design strikes a relatively good balance between strength and sharpness.

From the perspective of the processing experience, the advantages of this structure are mainly reflected in:

The blade tip has moderate rigidity.

Not easy to chip.

The cutting process is relatively stable.

Suitable for a variety of materials and operating conditions.

Therefore, triangular carbide inserts are often used in general-purpose turning operations, and they are equally suitable for both rough turning and semi-finishing.

Three, TNMG With TCMT Focus of use

Although both are triangular turning inserts, ... TNMG and TCMT There are still structural differences, making them suitable for different processing habits.

TNMG

Negative structure

The blade is thick.

High impact resistance

More suitable for applications with heavier loads.

TCMT

Positive structure

Cutting is smoother and lighter.

Better chip removal performance

Surface quality is easier to control.

In actual production, many workshops, depending on the different processes, will... TNMG and TCMT Use them in combination with each other.

4. Multiple groove types available to meet a wider range of machining requirements.

To accommodate different materials and processing methods, TNMG / TCMT The series offers a variety of common groove types:

Flat type

General-purpose

TM Slot

43 Slot

PV Slot

MA Slot

MS Slot

HK Slot

By combining different flute geometries, it’s possible to adjust the requirements for chip evacuation, stability, and cutting smoothness—all within the same insert geometry—thus reducing the hassle of frequently changing insert grades.

5. The material has a wide range of applicability and is suitable for processing multiple varieties.

Another advantage of triangular turning inserts is their strong material adaptability, making them suitable for a wide range of common and difficult-to-machine materials.

Steel parts

Stainless steel

Hardened steel parts and hardened stainless steel

Cast iron

Titanium alloy

High-temperature alloy

For processing sites with a wide variety of materials and frequently changing operating conditions, this versatility is highly practical.

Six, R The choice of angle directly affects the machining results.

TNMG / TCMT Offer different cutting edges. R Commonly used corner specifications include:

R8:

The blade tip is more robust, making it suitable for rough turning and larger cutting volumes.

R4:

The blade is sharper, making it ideal for semi-finishing and operations that demand high surface quality.

Through R The adjustment of the angle allows for flexible trade-offs between efficiency and surface quality.

7. Common Application Scenarios

In actual machining, triangular turning inserts are commonly used for:

External cylindrical turning

Face turning

Step machining

Internal Boring

As a universal cutting insert, it can both handle the task of removing excess material and perform relatively fine machining operations.

8. From a usage perspective, what are its advantages?

According to feedback from the workshop, TNMG / TCMT The advantage of triangular carbide inserts doesn't lie in any single parameter standing out particularly; rather, it lies in:

Wide range of uses

Not picky about operating conditions

Chip removal direction

The blade is wear-resistant and not easy to chip.

Good value for money

For users who prioritize stable machining and cost control, these blades tend to be easier to use over the long term.

If you need a turning insert that is highly versatile, has a stable lifespan, and is suitable for a wide variety of materials, then... TNMG / TCMT The triangular turning insert is a mature and reliable choice.

By reasonably selecting the groove type and R The tool can meet a variety of machining requirements, from rough turning to semi-finishing, making the turning process smoother and more controllable.

Recommended products