Product

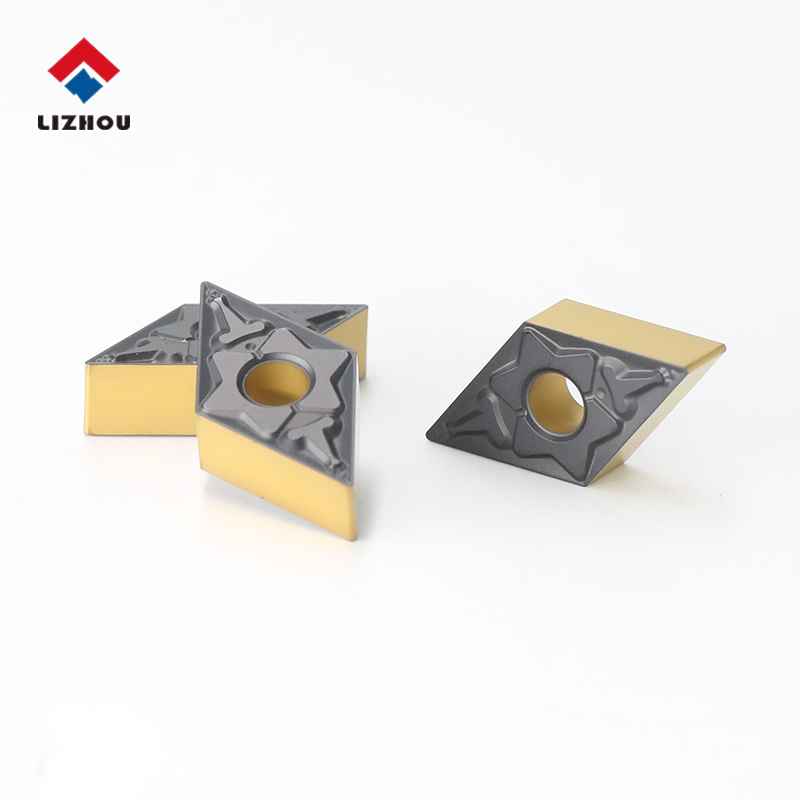

TCMT triangular turning insert

China Lizhou Hard Alloy Source Factory

Product Name:Triangular lathe tool

Coating : PVD

Brand number:LMP202

Classification :

Turning insert

keyword:

lizhou

TCMT Carbide Turning Inserts: TCMT090204, TCMT110204, TCMT16T304

As a leading carbide manufacturer, we provide world-class solutions for precision machining. Among our top-performing products are the TCMT series carbide turning inserts, including TCMT090204, TCMT110204, and TCMT16T304. These inserts are designed to deliver excellent wear resistance, cutting efficiency, and consistent surface quality, meeting the demands of industries such as automotive, aerospace, energy, and mold-making.

This article will cover a comprehensive product analysis, including:

The meaning of the TCMT code (letters and numbers)

Performance and advantages of carbide inserts

Dimensional parameters for each insert

Usage scenarios and functions

Key features and benefits

Cautions for use

Technical or patent innovations

By the end, you will understand why TCMT carbide inserts are among the most reliable choices for modern CNC machining and general turning operations.

Type | Basic Dimensions (mm) | Cutting Data | PVD | CVD | |||||

I.C | S | D | R | Cutting Depth (mm) | Feed Rate ( mm/tooth ) | LMP202 | LKC202 | LPC202 | |

TCMT 090204 | 5.56 | 2.38 | 2.50 | 0.4 | 0.6-1.5 | 0.03-0.15 | ⚪ |

|

|

TCMT 090208 | 5.56 | 2.38 | 2.50 | 0.8 | 0.6-1.5 | 0.05-0.15 | ⚪ |

|

|

TCMT 110204 | 6.35 | 2.38 | 2.80 | 0.4 | 0.80-2.00 | 0.05-0.20 | ⚪ |

|

|

TCMT 110208 | 6.35 | 2.38 | 2.80 | 0.8 | 0.80-2.50 | 0.07-0.20 | ⚪ |

|

|

TCMT 16T304 | 9.525 | 3.97 | 4.40 | 0.4 | 1.00-3.00 | 0.07-0.25 | ⚪ |

|

|

TCMT 16T308 | 9.525 | 3.97 | 4.40 | 0.8 | 1.00-3.00 | 0.09-0.25 | ⚪ |

|

|

1. Understanding the TCMT Insert Designation

Each TCMT code follows the ISO turning insert designation system:

T – Insert shape: Triangle (60° corner)

C – Relief angle: 7° clearance (ensures sharp cutting edge)

M – Tolerance class: Medium tolerance, balancing precision and cost

T – Type of chipbreaker / clamping hole style

Numbers (090204, 110204, 16T304) – Indicate size, thickness, and corner radius

Examples:

TCMT090204

09 = Cutting edge length (~9mm)

02 = Insert thickness (~2.38mm)

04 = Nose radius (0.4mm)

TCMT110204

11 = Cutting edge length (~11mm)

02 = Insert thickness (~2.38mm)

04 = Nose radius (0.4mm)

TCMT16T304

16 = Cutting edge length (~16mm)

T3 = Insert thickness (~3.97mm)

04 = Nose radius (0.4mm)

This naming system allows machinists to select the exact insert for their operation, ensuring compatibility with toolholders and turning machines.

2. Advantages of Carbide TCMT Inserts

Being a hard alloy (cemented carbide) manufacturer, our TCMT inserts are produced with high-performance tungsten carbide substrates and advanced coatings (CVD and PVD). Key benefits include:

High Hardness & Wear Resistance

Carbide hardness above 90 HRA ensures resistance against abrasive wear.

Thermal Stability

Coatings like TiN, TiCN, Al₂O₃, TiAlN protect the cutting edge under high temperatures.

Edge Sharpness

Positive rake angle improves sharpness, making TCMT inserts ideal for precision turning.

Excellent Surface Finish

Low cutting forces and good chip evacuation lead to superior surface quality.

Versatility

Works effectively on steel, stainless steel, cast iron, aluminum, copper alloys, and non-ferrous metals.

Cost Efficiency

Multi-edge design maximizes tool utilization and reduces cost per component.

3. Dimensional and Geometric Parameters

TCMT090204

Size: 9mm edge length

Thickness: ~2.38mm

Nose radius: 0.4mm

Application: Small workpieces, precision finishing

TCMT110204

Size: 11mm edge length

Thickness: ~2.38mm

Nose radius: 0.4mm

Application: General-purpose turning, medium-sized components

TCMT16T304

Size: 16mm edge length

Thickness: ~3.97mm

Nose radius: 0.4mm

Application: Larger components, roughing and semi-finishing

4. Usage Scenarios

Automotive Industry

Shafts, gears, brake systems, and precision engine parts.

Aerospace Industry

Lightweight alloys, titanium, and nickel-based superalloys.

Energy Sector

Turbine parts, oil & gas equipment, and power plant components.

General Engineering

Shafts, sleeves, pipes, and custom precision parts.

Mold and Die

Precision cutting of hardened steels in mold applications.

5. Functions and Roles

Turning Operations: External turning, facing, profiling, and contouring.

Material Flexibility: Effective on both soft alloys (aluminum, brass) and hard-to-cut materials (stainless steel, heat-resistant alloys).

Chip Control: Advanced chipbreaker designs minimize built-up edge.

Surface Accuracy: Ensures tight tolerances and fine finishes.

6. Features and Benefits

Positive Rake Angle: Reduces cutting forces, lowers power consumption.

Sharp Cutting Edge: Ideal for fine turning and finishing.

Wide Compatibility: Fits ISO-standard toolholders.

Multi-Coating Options: CVD and PVD coatings for optimized material performance.

High Productivity: Stable cutting at high speeds and feeds.

7. Cautions for Use

Correct Holder Selection

Match TCMT inserts with compatible ISO toolholders.

Cutting Parameters

Adjust cutting speed, feed, and depth according to workpiece material.

Coolant Application

Use coolant for stainless steel and heat-resistant alloys to extend tool life.

Indexing and Rotation

Replace or rotate inserts before excessive wear occurs.

Avoid Overloading

Excessive feed or depth of cut may cause premature edge chipping.

8. Technical and Patent Innovations

Our TCMT inserts incorporate proprietary technologies to enhance performance:

Nano-Layer Coating Technology

Multi-layer coatings improve wear and oxidation resistance.

Fine-Grain Carbide Substrates

Provides balance between hardness and toughness.

Advanced Chipbreaker Designs

Special geometries for smooth chip evacuation and stable cutting.

Customized Grades

Different carbide grades available for steel, stainless steel, cast iron, and non-ferrous metals.

9. Why Choose Our TCMT Inserts?

Direct Manufacturer Advantage: Lower costs and consistent quality.

Tailored Solutions: Inserts can be customized with coatings and chipbreaker geometries.

ISO Certified: Compliant with international standards.

Proven Global Applications: Widely used across Asia, Europe, and the Americas.

High ROI: Long tool life reduces downtime and costs.

Previous page

Next page

Use equipment

CNC machining centre

CNC machine tools

Carved machine

Factory Board

Factory Board

Factory Board

Factory Board

Factory Board

Recommended products

FAQ

2025-05-29

The naming conventions for turning inserts generally follow international standards (such as ISO standards). The model number consists of a series of letters and numbers, each character representing different geometric parameters or functional characteristics, such as the naming convention for the TNMG160404R-PV turning insert from Lizhou.

2025-05-26

What types of end mills are there?

Materials can be processed according to different types of end mills, categorized by the types of milling tools, including flat end mills, ball end mills, radius end mills, chamfer end mills, and end mills with chip breakers.

2025-05-23

PCD milling cutter is a polycrystalline diamond (PCD) milling cutter, which has a wide range of applications in the field of machining.

2025-05-08

End mill for machining aluminum materials

Many customers have told us that ordinary end mills frequently stick when machining aluminum, and the accumulation of chips affects the accuracy, so they always change the tools. LIZHOU editor suggests that coated end mills are not recommended for aluminum materials, because some coatings contain aluminum elements. Therefore, it is better to choose uncoated end mills when selecting end mills for machining aluminum materials.