Blog

FAQ

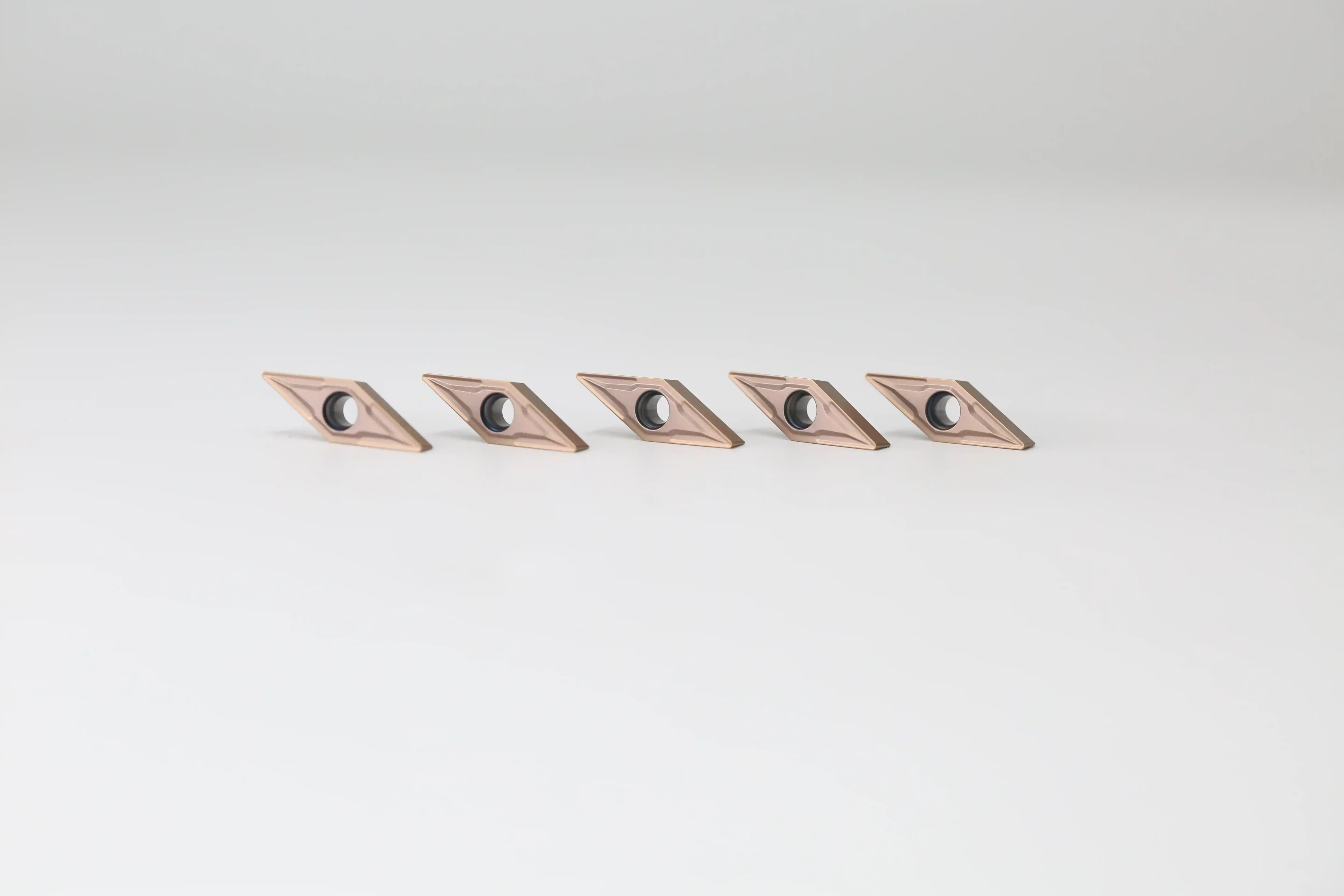

VCMT / VNMG 35° Diamond Turning Inserts | Precision Machining and Wear-Resistant Turning

35 °Rhombus Turning inserts ( VCMT / VNMG )—A practical choice that balances precision and durability.

In CNC turning, the geometric angles of the cutting insert, the form of the rake angle, and the groove design often directly determine the machining results.

Especially in the machining of external circles, internal holes, and end faces, improper blade selection can easily lead to issues such as vibration, noticeable tool marks, and a short tool life.

Laizhou's launch 35 ° Diamond turning insert VCMT With VNMG These two commonly used cutting tool types are specifically designed to meet different machining requirements. They can both satisfy the surface quality demands of precision finishing and also take into account the needs for wear resistance and stability, making them an extremely practical type of turning insert in the workshop.

One, 35 °The diamond-shaped structure is more suitable for precision turning and contour machining.

VCMT and VNMG Also belongs to 35 °Diamond-shaped turning insert.

Compared to 80 ° or 55 ° Diamond-shaped blade, 35 ° The advantage of a rhombus is:

The blade is sharper.

Easier to conform to the workpiece contour

Suitable for small cutting depths and small feed rates.

More friendly to contouring, chamfering, and end-face finishing.

Therefore, blades of this type are used very frequently in finishing and semi-finishing operations.

II. VCMT Positive rake angle design for smooth cutting and improved surface quality.

VCMT Adopting a positive rake angle design, the cutting edge is sharper, which in actual machining manifests as:

Low cutting resistance \ Chip removal is smooth. \ The cutting process is smoother. \ Less vibration \ High surface finish of the workpiece

This characteristic enables... VCMT More suitable for: Light cutting \ Finishing \ Low-feed machining method

Parts with high surface quality requirements

When machining ordinary steel parts and stainless steel, VCMT It can achieve a relatively ideal surface effect.

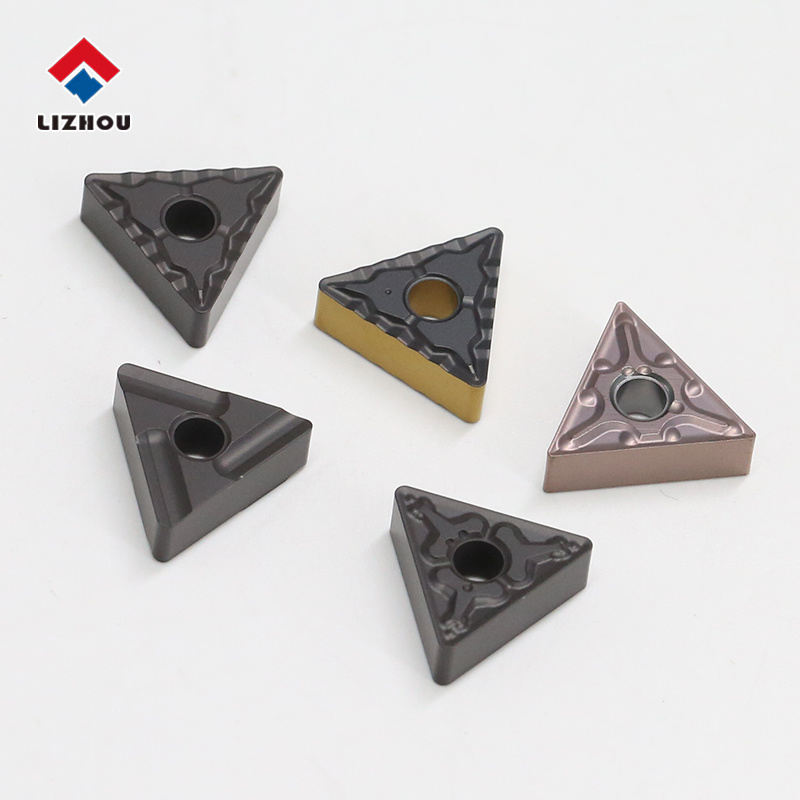

Three, VNMG Negative rake design for enhanced wear resistance and chipping resistance.

With VCMT Different, VNMG Adopting a negative rake angle design, the overall structure is stronger and the cutting edge is more durable.

Its main features include: excellent wear resistance, strong resistance to chipping, greater cutting force, and suitability for higher-load operating conditions.

Therefore, VNMG More suitable for:

Machining with high tool durability requirements, materials with good rigidity, and stable, continuous machining scenarios.

In applications involving the machining of hardened steel parts or where longer tool life is required, VNMG The advantage will become even more apparent.

Four, R Flexible angle selection balances smoothness and durability.

This series offers R4 and R8 Two specifications for tool tip radii:

R4:

The blade is sharper.

Better surface finish

Suitable for finishing

R8:

The blade tip has higher strength.

Better wear resistance

More suitable for longer, continuous machining.

Users can flexibly select the appropriate option based on their requirements for machining accuracy and service life. R Corner.

5. Multiple groove types available to suit different materials and operating conditions.

Lizhou this series 35 ° The diamond-shaped cutting tool offers a variety of groove types to choose from:

Universal groove type:

Suitable for conventional turning operations, with a wide range of applications.

MA Slot type:

Favors stable cutting and is suitable for medium-load machining.

MS Slot type:

Pays more attention to chip removal and cutting stability.

The design of different groove types enables the cutting blade to maintain a good machining condition in various turning operations, including external cylindrical turning, internal bore turning, and end-face turning.

6. The coatings are clearly distinguished, making selection more intuitive.

To make it easier for users to select the right model, this series also features distinctions in coating:

Gray-black universal coating:

Suitable for machining both ordinary steel parts and stainless steel, with a wide range of applications.

Bronze-colored hard coating:

More suitable for machining hardened steel parts and hardened stainless steel, with enhanced wear resistance.

This distinction makes it easier and faster for users to match materials in actual use.

7. High-quality tungsten steel matrix ensures long-term stability.

VCMT With VNMG The blades are all made from high-quality tungsten steel and feature:

High hardness, excellent wear resistance, stable cutting edge, and resistant to chipping even under high-speed cutting.

In common machining processes such as external cylindrical turning, internal bore turning, and end-face machining, it can maintain a long tool life and stable machining performance.

If you’re looking for a turning insert that balances fine finishing performance with durability, 35 ° Diamond-shaped VCMT and VNMG These are all very mature and reliable choices.

VCMT More focused on precision cutting and surface quality, VNMG It places greater emphasis on wear resistance and stability. By appropriately combining groove geometry, coating, and... R Angles can cover most turning machining scenarios.

Lizhou turning inserts—focused on practicality and stability—are worthy of long-term use in actual machining operations.

Recommended products