Blog

FAQ

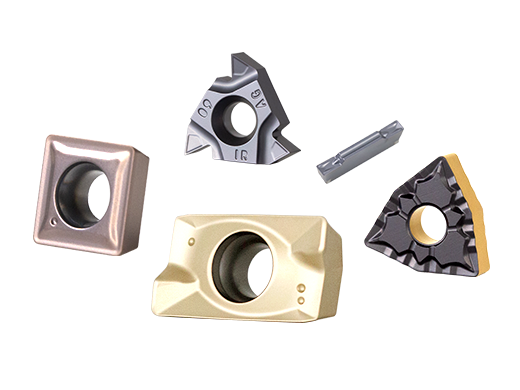

Processing blades: turning, cemented carbide and lathe blade exploration

Turning carbide inserts

Carbide inserts specifically designed for turning processes. The design of the tip angle and chip breaker is tailored to turning needs. Coatings often use high-temperature resistant coatings to adapt to the high-temperature environment of continuous cutting in turning.

Mainly used on lathes to process rotating metal workpieces.

For example, CVD coated rhombic inserts CNMG-MA series, suitable for rough machining of steel or cast iron. / precision machining

Carbide cutting tool inserts

A broad term for carbide inserts, encompassing various processing types, applicable to turning inserts, milling inserts, U drilling inserts, cutting and grooving, etc., all of which can be called carbide cutting tool inserts.

Diverse shape designs: triangular, square, round; edge treatments include sharp and chamfered types, varying according to processing needs. Types vary depending on processing needs

Can be used with various processing materials, such as stainless steel, titanium alloys, steel, cast iron, etc.

For example: milling uses APKT inserts, turning uses TNMX inserts

Metal lathe inserts

Inserts specifically for lathes; materials are not limited to carbide, although carbide is mainstream, but may also include high-speed steel, ceramics, or CBN Lathes are specifically designed, emphasizing compatibility with the lathe tool holder.

Processing objects: generally metallic materials (steel, aluminum, cast iron, etc.)

previous page

Recommended products