Blog

FAQ

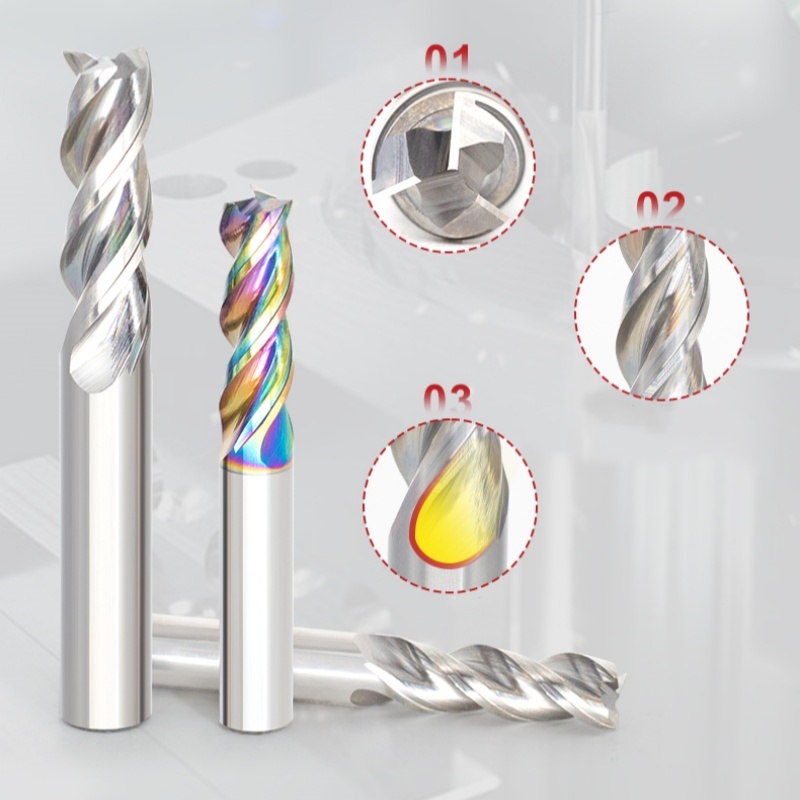

Lizhou High-Speed Steel End Mill: Precision Quenching, High-Efficiency Milling

As a manufacturer of cemented carbide tools deeply rooted in the cutting tool industry 32 years, Lizhou brand always adheres to the " Hard Quality, Soft Service ” as its core concept

It is not only known in the industry for its cemented carbide cutting tools, but also relies on high-performance high-speed steel end mill series to redefine the efficiency and reliability of precision machining.

Why choose Lizhou high-speed steel end mills?

1. Material Guarantee: Double Breakthrough in Hardness and Toughness

We use Cobalt-containing high-speed steel ( HSS-E,M42/M35 grade) base material. Through vacuum heat treatment and cryogenic technology, the hardness of the tool is stably maintained at HRC64-66,红硬性提升至 600℃ 。

Under continuous high-temperature cutting conditions, the cutting edge can still maintain excellent wear resistance, avoiding chipping caused by thermal softening.

2. Precise Cutting Edge Design: 0.01mm Ultimate Control

The helix angle of Lizhou end mills is optimized through CFD Computational Fluid Dynamics simulation and combined with 40°-45° rake angle design significantly improves chip removal efficiency and reduces the phenomenon of tool sticking during processing.

The runout of the cutting edge is strictly controlled within 0.01mm以内 It is especially suitable for the fine machining of cavities in difficult-to-machine materials such as die steel (such as SKD11、NAK80 ) and stainless steel ( SUS304、316L )

We use a five-axis CNC grinding machine to create a nano-level cutting edge, reducing cutting resistance 15% and achieving a surface roughness of Ra0.4μm 。

3. Full-Scenario Adaptability: 20+ models cover the entire roughing and finishing process

According to processing needs, Lizhou provides 2 edge, 3 edge, 4 edge flexible configuration schemes and recommends the following star models:

LZ-MS-4F ( 4 4-edge square end mill) Suitable for efficient fine machining of non-ferrous metals such as aluminum alloy and brass, with a speed of up to 8000rpm and an improved feed rate of 20%。

LZ-MS-2B ( 2 long-neck ball end mill) Specifically designed for deep cavity molds (depth-diameter ratio 5:1 ) TiN coating reduces frictional heat and extends service life by 3 times.

LZ-MS-R6 ( 6mm Round nose end mill) Optimized for stainless steel surface machining, 0.2mm tip radius accuracy avoids tool marks.

Lizhou Service: Full-Chain Empowerment from Products to Solutions

We practice " Hard Quality, Soft Service ” concept and provide you with:

√ 100% Full Inspection Quality Control Each tool undergoes three quality inspections before leaving the factory to ensure dimensional tolerance ≤±0.005mm 。

√ Non-standard Customization Supports 3-20mm customization of special sizes, special shapes, and coatings ( TiAlN/DLC ) 7 delivery within days.

√ Technical Response System A professional technical team provides selection guidance, cutting parameter optimization, and on-site problem diagnosis, 24 hours emergency response.

Choosing Lizhou high-speed steel end mills is not just choosing a tool, but also choosing 32 years of cemented carbide technology accumulation and millimeter-level precision commitment 。

Recommended Matching Scheme :

Roughing: MS-4BL -4R ( 4 4-edge round nose end mill) + High-pressure flushing of cutting fluid → Improved metal removal rate 30%

Finishing: MS-3E ( 3 4-edge ultra-precision end mill) + Minimum Quantity Lubrication ( MQL ) → Surface finish reaches mirror level

Recommended products