Product

JDMT fast feed milling cutter

China Lizhou Hard Alloy Source Factory

Product Name: Fast feed milling cutter

Coating : PVD

Material:Tungsten steel

Classification :

Milling insert

keyword:

lizhou

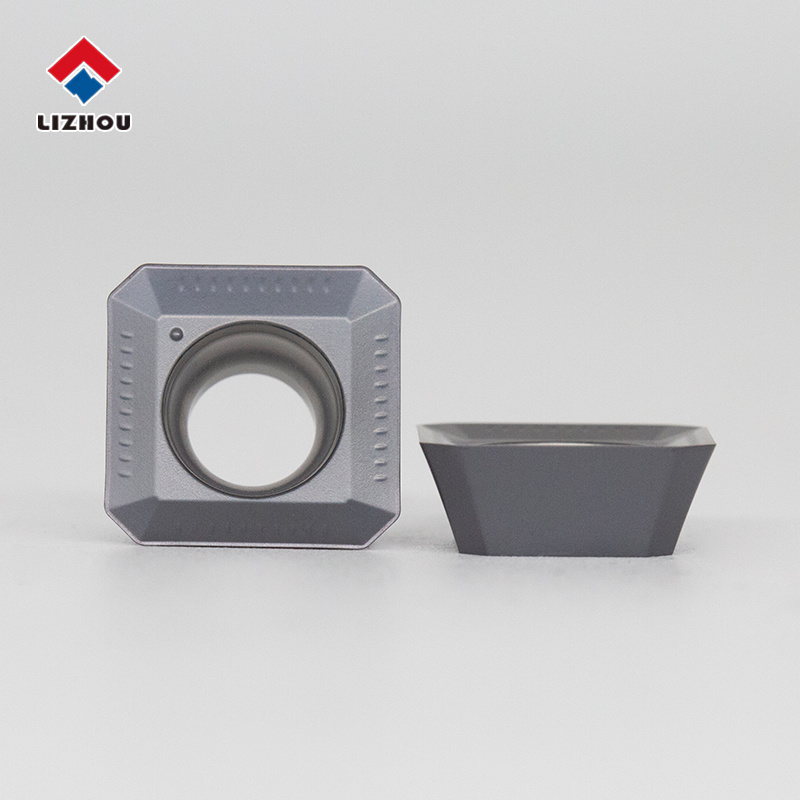

JDMT070204R Carbide Milling Insert – Precision, Performance, and Innovation

Introduction

In modern machining industries, the demand for high-efficiency, precision-driven, and durable cutting tools is greater than ever. From automotive and aerospace to mold-making and general engineering, manufacturers rely on inserts that can withstand challenging conditions, deliver consistent accuracy, and maximize tool life.

The JDMT070204R carbide milling insert is designed to meet these exacting requirements. Manufactured with advanced carbide technology, it offers superior wear resistance, optimized chip evacuation, and reliable cutting stability. In this article, we will explore in detail the performance advantages, technical specifications, applications, features, precautions, and potential innovations associated with the JDMT070204R insert, while also analyzing its alphanumeric code for deeper understanding.

Understanding the Designation: JDMT070204R

The alphanumeric code JDMT070204R follows ISO industry standards, providing essential insights into the insert’s geometry and design.

J – Indicates the insert shape (commonly referring to an 85° parallelogram design for specialized milling applications).

D – Stands for relief angle or clearance angle, typically 15°, which ensures optimized contact and reduces friction during cutting.

M – Represents the tolerance class, typically "M" meaning medium precision suitable for both finishing and general milling operations.

T – Describes the type of chipbreaker or cutting geometry, often optimized for chip evacuation in milling.

07 – The insert’s cutting edge length in millimeters (approx. 7 mm), compact yet effective for fine-to-medium milling.

02 – Denotes the insert thickness (approx. 2.4 mm), balancing rigidity with cutting sharpness.

04 – Specifies the corner radius (0.4 mm), ideal for achieving smoother surface finishes without excessive cutting forces.

R – Indicates right-hand cutting direction.

This nomenclature reveals that the JDMT070204R insert is engineered for precision milling, providing versatility across different operations.

Advantages of Carbide Technology

The JDMT070204R is manufactured from high-performance tungsten carbide substrate, enhanced with multi-layer PVD or CVD coatings depending on the target application. The advantages of this carbide foundation include:

High Hardness and Wear Resistance – Ensures excellent performance under high-speed cutting and abrasive conditions.

Thermal Stability – Withstands temperatures above 1000°C, crucial for dry or semi-dry machining.

Toughness Balance – Carbide substrate resists chipping and fracture under interrupted cuts.

Extended Tool Life – Reduced downtime for tool changes, improving machining efficiency.

Versatility – Suitable for steel, stainless steel, cast iron, and some non-ferrous metals.

Performance Analysis of JDMT070204R

1. Cutting Efficiency

The sharp edge preparation and optimized geometry minimize cutting forces, allowing higher feed rates without sacrificing accuracy.

2. Surface Finish

With its 0.4 mm corner radius, the JDMT070204R provides smooth and consistent surface finishes, making it suitable for semi-finishing and finishing passes.

3. Chip Evacuation

The T-type chipbreaker design enhances chip curling and evacuation, reducing the risk of chip re-welding and workpiece damage.

4. Stability

Its medium tolerance class balances flexibility and accuracy, ensuring stable performance in both roughing and finishing.

5. Cost-Effectiveness

Durability combined with reduced machine downtime translates into lower cost per component for manufacturers.

Applications of JDMT070204R

The JDMT070204R carbide milling insert is suitable for a wide range of industrial machining scenarios:

Automotive Manufacturing – Engine blocks, transmission housings, and structural parts.

Aerospace Components – Aluminum alloys, titanium parts, and high-strength steels.

Mold and Die Industry – Precision surface milling of hardened steels.

General Engineering – Suitable for slotting, pocket milling, and contouring.

Stainless Steel Processing – Chipbreaker design prevents work hardening issues.

Its adaptability allows it to serve both CNC machining centers and manual milling setups.

Key Features

85° Shape: Provides strength at the cutting edge, reducing risk of fracture.

Multi-Layer Coating: Enhances tool life and resistance to built-up edge.

High Edge Sharpness: Reduces cutting forces, ideal for precision machining.

Optimized Corner Radius: Balances strength with finishing quality.

Right-Hand Cutting: Standard for most milling machines, ensuring compatibility.

Precautions for Use

To achieve maximum performance and longevity, the following guidelines should be observed:

Correct Cutting Parameters – Match spindle speed, feed per tooth, and depth of cut with recommended values for carbide inserts.

Stable Clamping – Ensure the insert is properly seated in the milling cutter pocket to prevent vibration or breakage.

Appropriate Coolant Use – Apply coolant for stainless steel and heat-resistant alloys, while dry cutting is possible for cast iron.

Regular Inspection – Replace inserts showing wear land or micro-chipping to maintain surface quality.

Avoid Overloading – Do not exceed the insert’s designed cutting depth to prevent premature failure.

Technical or Patent Innovations

Our carbide inserts, including the JDMT070204R, incorporate cutting-edge innovations:

Nano-Coating Technology – Advanced PVD coatings with nano-layer structures for improved adhesion and reduced wear.

Edge Preparation Technology – Micro-honing for better cutting stability and longer edge life.

Optimized Chipbreaker Geometry – Engineered through CAD/CAE simulations for better chip flow in high-speed milling.

Heat-Resistant Substrates – Specially sintered carbide compositions offering resilience under dry and high-speed conditions.

These innovations make JDMT070204R a competitive and reliable choice for manufacturers aiming for higher productivity.

Why Choose JDMT070204R from Our Company?

As a professional carbide manufacturer, our company offers not only inserts like the JDMT070204R but also customized cutting solutions to meet diverse customer requirements. By controlling the entire production chain — from carbide powder preparation to precision grinding and coating — we ensure consistent quality, competitive pricing, and global support.

Conclusion

The JDMT070204R carbide milling insert represents the perfect combination of strength, precision, and innovation. With its carefully engineered geometry, carbide toughness, and advanced coatings, it offers manufacturers the ability to machine a variety of materials with high efficiency and accuracy.

Whether applied in automotive, aerospace, mold-making, or general engineering, the JDMT070204R delivers cost-effective machining solutions while ensuring reliability and long tool life. For companies seeking to stay competitive in today’s demanding manufacturing landscape, this insert is a proven solution.

Previous page

Next page

Use equipment

CNC machining centre

CNC machine tools

Carved machine

Factory Board

Factory Board

Factory Board

Factory Board

Factory Board

Recommended products

FAQ

2025-05-29

The naming conventions for turning inserts generally follow international standards (such as ISO standards). The model number consists of a series of letters and numbers, each character representing different geometric parameters or functional characteristics, such as the naming convention for the TNMG160404R-PV turning insert from Lizhou.

2025-05-26

What types of end mills are there?

Materials can be processed according to different types of end mills, categorized by the types of milling tools, including flat end mills, ball end mills, radius end mills, chamfer end mills, and end mills with chip breakers.

2025-05-23

PCD milling cutter is a polycrystalline diamond (PCD) milling cutter, which has a wide range of applications in the field of machining.

2025-05-08

End mill for machining aluminum materials

Many customers have told us that ordinary end mills frequently stick when machining aluminum, and the accumulation of chips affects the accuracy, so they always change the tools. LIZHOU editor suggests that coated end mills are not recommended for aluminum materials, because some coatings contain aluminum elements. Therefore, it is better to choose uncoated end mills when selecting end mills for machining aluminum materials.