Product

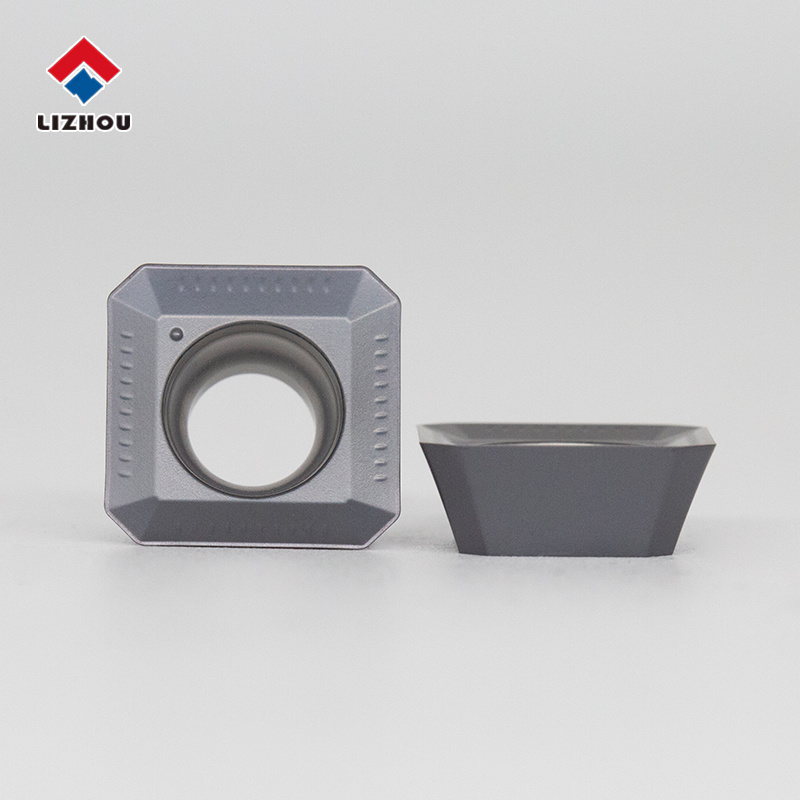

APMT1135/1604 milling insert

China Lizhou Hard Alloy Source Factory

Product Name: milling insert

Coating : PVD

Material:Tungsten steel

Classification :

Milling insert

keyword:

lizhou

APMT1135 Carbide Milling Insert – High-Performance Indexable Insert for Precision Machining

Introduction

In modern machining, efficiency, durability, and precision are the most important requirements for cutting tools. Carbide milling inserts play a vital role in industries such as automotive, aerospace, mold-making, and general engineering, where reliable and consistent cutting performance directly impacts production cost and product quality.

The APMT1135 carbide milling insert is one of the most commonly used indexable inserts worldwide, recognized for its versatility, long tool life, and excellent surface finish. Manufactured with advanced tungsten carbide substrates and PVD/CVD coatings, it offers superior cutting performance across a wide range of materials, from steels and stainless steels to cast iron and non-ferrous metals.

This article provides a detailed technical overview of the APMT1135, including code interpretation, performance benefits, applications, features, precautions, and innovations, to help engineers, buyers, and manufacturers understand why it is the right choice for high-performance machining.

Breaking Down the Code: APMT1135

Like all ISO-standardized inserts, the designation APMT1135 carries important information about its geometry and size:

A → Insert shape, typically 85° parallelogram, suitable for face milling and pocket milling.

P → Relief angle, usually 11°, ensuring low friction and better clearance.

M → Tolerance class, M = medium, balancing precision and general usability.

T → Clamping method and chipbreaker style, optimized for stable cutting.

11 → Insert length, approx. 11 mm, compact but efficient.

35 → Insert thickness/nose radius (varies by standard), often interpreted as 3.5 mm thickness or 0.35 mm nose radius depending on manufacturer.

Together, APMT1135 defines a versatile milling insert widely used in indexable end mills and face mills for medium to finishing operations.

Advantages of APMT1135 Carbide Inserts

The APMT1135 carbide insert offers multiple benefits over traditional high-speed steel (HSS) or uncoated tools:

High Hardness & Wear Resistance – Tungsten carbide provides extreme hardness for long tool life.

Thermal Stability – Excellent heat resistance allows cutting speeds up to 3–5 times higher than HSS.

Versatile Applications – Suitable for steels, stainless steels, cast iron, aluminum, and some superalloys.

Cost Efficiency – Indexable design allows insert replacement without changing the whole tool.

Consistent Performance – High-precision grinding ensures stable machining results.

Surface Finish Quality – Nose radius provides smoother surface finish in finishing operations.

Performance Benefits

The APMT1135 is engineered for medium to finishing milling applications, offering:

Reduced Cutting Forces – Optimized chipbreaker lowers tool pressure, improving tool life.

Excellent Chip Control – Prevents built-up edge and chip entanglement, especially in stainless steel.

High Material Removal Rate (MRR) – Enables higher productivity in CNC milling centers.

Improved Tool Stability – Insert geometry minimizes vibrations, enhancing dimensional accuracy.

Extended Tool Life – Multi-layer coatings protect against abrasion and oxidation.

Application Fields

The APMT1135 carbide insert finds wide use in industrial machining, including:

Automotive – Cylinder heads, transmission housings, and precision automotive parts.

Aerospace – Structural aluminum parts, titanium alloys, and heat-resistant materials.

Mold and Die Industry – Surface finishing of hardened steel molds.

General Engineering – Slotting, contouring, shoulder milling, and pocketing operations.

Stainless Steel Machining – Excellent chip evacuation reduces work-hardening.

Its adaptability makes it a go-to choice for CNC milling machines around the globe.

Key Features

85° Parallelogram Shape – Provides stable edge support.

11 mm Length – Compact, suitable for indexable end mills.

3.5 mm Thickness – Strong insert body for longer life.

Medium Tolerance (M) – Balances precision and versatility.

Advanced Coatings – CVD and PVD coatings ensure better tool life across different work materials.

Positive Rake Geometry – Smooth cutting with reduced energy consumption.

Precautions for Use

To maximize the performance of APMT1135 carbide inserts, follow these best practices:

Correct Cutting Parameters – Use manufacturer-recommended speeds and feeds.

Proper Clamping – Ensure the insert is seated correctly in the toolholder to avoid vibration.

Coolant Selection – Apply coolant for stainless steel and superalloys; dry machining can be used for cast iron.

Monitor Wear – Replace inserts when flank wear exceeds 0.3 mm or when chipping occurs.

Avoid Excessive Depth of Cut – Exceeding insert limits may cause premature tool failure.

Technical and Patent Innovations

Our APMT1135 inserts integrate cutting-edge innovations:

Nano-Layer Coatings – Improve heat resistance and reduce friction.

Optimized Chipbreaker Design – CAD-engineered for smooth chip flow.

Ultra-Fine Carbide Grain Substrate – Ensures balance between toughness and hardness.

Laser Edge Preparation – Uniform cutting edges reduce tool breakage.

Advanced Powder Metallurgy – Guarantees consistency in microstructure.

These innovations make the APMT1135 an ideal solution for demanding, high-precision industries.

Why Choose Our APMT1135?

As a professional carbide manufacturer, we deliver not only inserts but also:

Strict Quality Assurance – From carbide powder synthesis to final inspection.

OEM/ODM Services – Custom inserts available for specific machining needs.

Competitive Pricing – Direct factory supply for better cost efficiency.

Global Service – Trusted by clients in Asia, Europe, Africa, and the Americas.

Technical Support – Application guidance for best cutting performance.

By choosing our APMT1135, manufacturers benefit from higher efficiency, longer tool life, and reduced production costs.

Conclusion

The APMT1135 carbide milling insert is a versatile, reliable, and high-performance cutting solution for modern machining. With its optimized geometry, robust carbide substrate, and advanced coating technology, it ensures outstanding performance in medium and finishing milling applications across multiple industries.

Backed by our company’s expertise in carbide manufacturing, innovation in chipbreaker design, and strict quality control, the APMT1135 stands as a benchmark product in the carbide tooling market.

For manufacturers seeking to increase productivity, extend tool life, and improve machining quality, the APMT1135 is the trusted choice.

Previous page

Next page

Use equipment

CNC machining centre

CNC machine tools

Carved machine

Factory Board

Factory Board

Factory Board

Factory Board

Factory Board

Recommended products

FAQ

2025-05-29

The naming conventions for turning inserts generally follow international standards (such as ISO standards). The model number consists of a series of letters and numbers, each character representing different geometric parameters or functional characteristics, such as the naming convention for the TNMG160404R-PV turning insert from Lizhou.

2025-05-26

What types of end mills are there?

Materials can be processed according to different types of end mills, categorized by the types of milling tools, including flat end mills, ball end mills, radius end mills, chamfer end mills, and end mills with chip breakers.

2025-05-23

PCD milling cutter is a polycrystalline diamond (PCD) milling cutter, which has a wide range of applications in the field of machining.

2025-05-08

End mill for machining aluminum materials

Many customers have told us that ordinary end mills frequently stick when machining aluminum, and the accumulation of chips affects the accuracy, so they always change the tools. LIZHOU editor suggests that coated end mills are not recommended for aluminum materials, because some coatings contain aluminum elements. Therefore, it is better to choose uncoated end mills when selecting end mills for machining aluminum materials.