Blog

FAQ

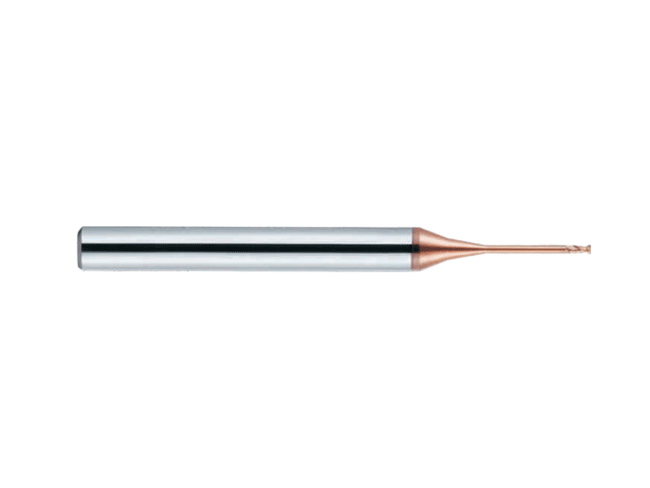

70° U-shaped 2-flute ball-end milling cutter made of tungsten steel for rough machining of hardened steel

In the machining industry, machining HRC65 When machining the following hardened steels, tool steels, and die steels, the requirements for cutting tools are often higher than those for ordinary steels: high chip evacuation is essential, cutting resistance is significant, and machining temperatures run high. Even a slight oversight can lead to issues such as chipping, tool breakage, and deep tool marks. Particularly during the roughing stage, cutting tools must possess strong chip-evacuation capabilities and high metal removal rates to ensure machining efficiency.

The tungsten steel we’re bringing you today. 70 degree You U Groove 2 End-mill cutter with blade head Featuring a higher-performance tool substrate paired with an optimized structural design, this tool is specifically developed for rough machining of hardened steels and the machining of complex curved surfaces. It is ideal for die and mold manufacturing shops, parts manufacturing companies, and... CNC An efficient tool for the machining workshop.

One, 70 Tungsten steel bar stock, specially designed for HRC65 Made from the following hardened steel

The superior the tool substrate, the more reliable the stability during cutting. This series features high hardness and high toughness. 70 Tungsten steel bar stock with: superior chipping resistance, enhanced wear resistance, higher thermal stability, and greater flexural strength.

Processing materials frequently searched by customers: HRC60 – 65 Hardened steel, various high-hardness tool steels (such as SKD11、D2、 Cr12 etc.), rough machining of mold steel cavities, high-strength martensitic stainless steel

The cutting tool maintains stability even under high-intensity cutting, reducing the number of tool changes and improving the overall processing efficiency of the operation.

II. You U The groove design ensures exceptionally smooth chip removal, making it the perfect choice for rough machining.

During rough machining, large cutting volumes generate abundant and hard chips. If chip removal capability is insufficient, it can easily lead to: tool overheating, edge burnout, chip jamming, tool collisions, abnormal tool marks, and a significant reduction in tool life.

This series adopts You U The large chip-groove design significantly enhances chip removal efficiency: The wider groove allows chips to flow out smoothly, reduces chip accumulation in the tool slot, lowers the temperature rise during machining, and minimizes cutting edge wear. It also supports higher feed rates and deeper cuts, thereby boosting metal removal rates. MRR )

It is particularly effective for roughing deep cavities, milling mold cavities, and large-scale rolling of steel parts.

Three, 2 Blade structure ensures smooth cutting and higher feed rates for greater stability.

Two-flute ball-nose end mills have long been regarded as the “efficiency leaders” among roughing tools, for the following reasons:

The two cutting edges make the groove wider, providing optimal chip removal capability.

Lower cutting resistance, lighter and faster tool.

More suitable for roughing with large cutting depths.

The tool has low vibration and is more durable.

For hardened steel, reducing cutting resistance. = Extend tool life.

4. Hemispherical blade tip, capable of machining various complex curved surfaces and cavity contours.

The greatest advantage of ball-end mills is their “strong capability for machining curved surfaces,” making them particularly well-suited for: molds. R Corner grooves, arc-transition surfaces, and curved cutting in deep cavities, 3D Contour machining, curved surface trimming, and chamfer transitions

The hemispherical cutter tip is less likely to chip than a sharp-cornered cutter, offering greater stability in continuous surface machining and producing more uniform tool marks.

5. Support non-standard customization to meet various processing conditions.

Lizhou Tools can be customized according to customers’ workpiece requirements: Special. R Value, special blade length, handle length, extended neck, slim handle, special groove or blade tip shape, custom coating, OEM/ODM Batch service

Whether it's deep cavity machining, long overhang machining, or complex mold structures, we can provide tailored tooling solutions.

Six: Why processing plants all love this product. 70 degree 2 blade You U Slotting ball-end mill?

From the customer's perspective, its advantages are very obvious:

Chip removal is smooth, chips are unlikely to get stuck, and the blade doesn't overheat.

Strong roughing capability, suitable for high feed rates and deep cuts.

Resistant to chipping, stable lifespan, and reduced tool change frequency.

Smooth cutting can also be maintained when machining hardened steel.

Surface machining finish is more stable.

Superior performance compared to traditional ball-end mills, with more cost-effective pricing.

Whether it's for molds, mechanical parts, or precision structural components, it can significantly enhance overall machining efficiency.

Recommended products