Blog

Can tungsten carbide drills be used on aluminum?

1、 How to optimize the efficiency of slotting tools?

When cemented carbide blades are equipped with innovative geometric structures:

Aluminum chips are forcibly segmented (passive chip removal efficiency ↑40% )

Cutting vibration is actively suppressed by the asymmetric cutting edge

Cutting tip heat is acceleratedly exported by the internal cooling channel (temperature ↓45% )

2 Can carbide drills be used for aluminum?

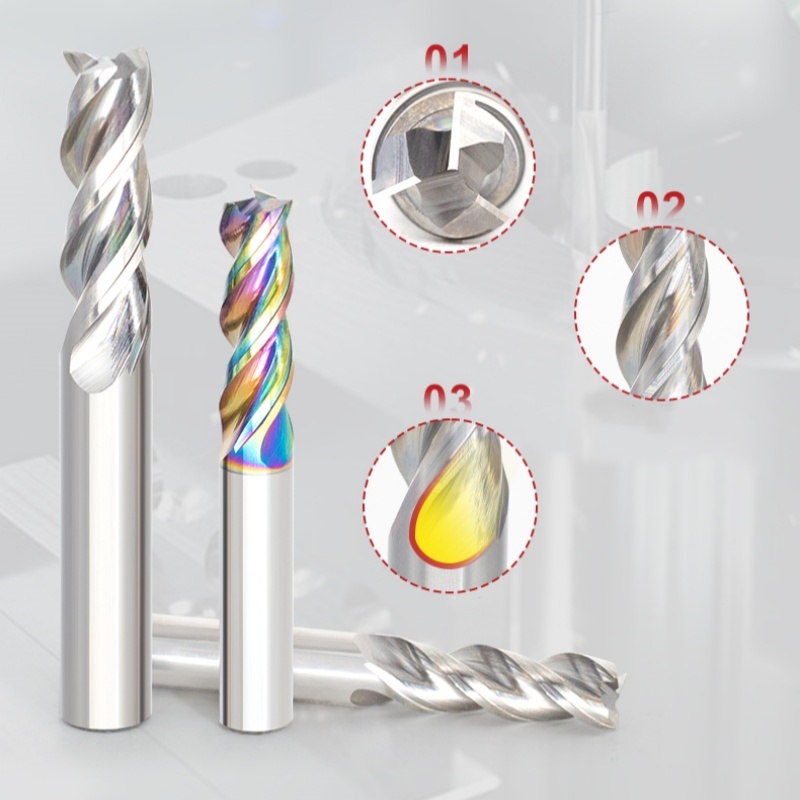

Sharp cutting edge Actively cuts the viscous aluminum chips, preventing built-up edge from damaging the workpiece

PVD Nano coating Passively reduces the friction coefficient and improves surface finish 50% Above

Large chip groove design Allows cutting fluid to fully penetrate, extending tool life.

3、 Recommended slotting blades :

Core Technology | Applicable Scenarios | |

|---|---|---|

SNMG120408-MD | Cobalt matrix + Magnetic coding layer ( 8% Co ) | Steel heavy load slotting, detection rate > 99% |

VCGT110302-RF | Tantalum wire RF marking, high temperature resistance 900℃ | Titanium alloy medical parts precision slotting |

4 New energy vehicle battery box processing cases :

Using ' Lizhou' VCGT110302 blades After:

Slotting efficiency actively improved 32% ( Vc=350m/min )

Tool debris 100% Is intercepted by the production line detector

Passive breakthrough in single blade processing capacity 1,500 Pieces

Slotting blades and blades for aluminum alloy processing are available from our Lizhou Cemented Carbide Co., Ltd. If you need recommendations for other models, please scan the code to join. ~

next page

Recommended products