Product

DNMG-TM steel turning inserts

China Lizhou Hard Alloy Source Factory

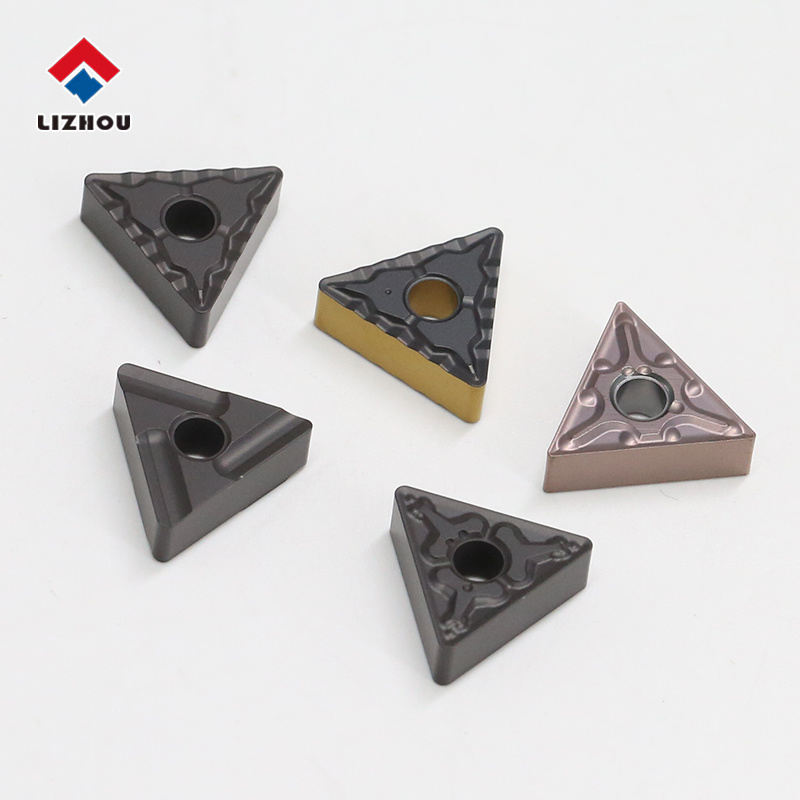

Product Name:Steel Turning Inserts

Coating : CVD

Brand number:LPC202

Classification :

Turning insert

keyword:

lizhou

DNMG150404-MA, DNMG150408-TM & DNMG150608-TM Carbide Turning Inserts – High-Performance Solutions for Modern Machining

Introduction

In the field of precision machining, the choice of cutting inserts plays a decisive role in productivity, tool life, and surface quality. Among the most versatile and widely used geometries are the DNMG carbide inserts, specifically DNMG150404-MA, DNMG150408-TM, and DNMG150608-TM. These inserts, engineered from advanced cemented carbide, deliver superior cutting performance across steel, stainless steel, and cast iron applications.

As a professional hard alloy manufacturer, our company develops these inserts using state-of-the-art powder metallurgy, nano-coating technologies, and advanced chip breaker designs. This article provides an in-depth analysis of their advantages, code meaning, dimensional parameters, application scenarios, features, precautions, and technical innovations.

Type | Basic Dimensions (mm) | Cutting Data | CVD | ||||||

I.C | S | D | R | Cutting Depth (mm) | Feed ( mm/tooth ) | LPC102 | LPC202 | LPC302 | |

DNMG 150404-TM | 12.70 | 4.76 | 5.16 | 0.4 | 0.60-4.00 | 0.15-0.30 |

| ⚪ |

|

DNMG150408-TM | 12.70 | 4.76 | 5.16 | 0.8 | 1.20-4.00 | 0.15-0.30 |

| ⚪ |

|

DNMG150412-TM | 12.70 | 4.76 | 5.16 | 1.2 | 1.80-4.00 | 0.15-0.30 |

| ⚪ |

|

DNMG150604-TM | 12.70 | 6.35 | 5.16 | 0.4 | 0.60-4.00 | 0.15-0.50 |

| ⚪ |

|

DNMG150608-TM | 12.70 | 6.35 | 5.16 | 0.8 | 1.20-4.00 | 0.20-0.50 |

| ⚪ |

|

DNMG150612-TM | 12.70 | 6.35 | 5.16 | 1.2 | 1.80-4.00 | 0.20-0.50 |

| ⚪ |

|

1. Advantages of DNMG Carbide Inserts

High Wear Resistance – Submicron carbide substrates paired with advanced PVD/CVD coatings extend tool life under high-speed conditions.

Versatility – DNMG inserts are suitable for both finishing and roughing operations, making them a go-to solution in turning.

Cost Efficiency – Multi-edged design allows multiple reindexings, reducing tooling costs.

Enhanced Stability – Negative-rake geometry provides rigidity, making it suitable for interrupted cutting and heavy-duty machining.

Consistent Surface Finish – Optimized chip breakers (MA, TM types) ensure smooth chip evacuation, minimizing vibration and tool chatter.

2. Decoding the Insert Code (ISO Standard)

Let’s break down the designation DNMG150404-MA as an example:

D – Insert shape: 55° diamond rhombic (versatile for profiling and turning).

N – Clearance angle: 0° (negative insert, strong cutting edge, suitable for heavy cutting).

M – Tolerance class: ±0.05 mm, ±0.13° (medium precision).

G – Insert type: Single-sided with hole and chipbreaker.

Numerical values:

15 – Inscribed circle (IC) ≈ 15.875 mm.

04 – Insert thickness ≈ 4.76 mm.

04 / 08 – Nose radius: 0.4 mm, 0.8 mm.

06 – Nose radius: 0.6 mm (for 150608).

Suffix (chipbreaker designation):

MA – Medium application chipbreaker, optimized for finishing to medium turning, with excellent chip control on steels and stainless steel.

TM – Tough machining chipbreaker, designed for medium to roughing operations, ideal for stainless steel and difficult-to-cut alloys.

3. Performance Analysis

(1) Cutting Geometry

DNMG inserts feature a 55° diamond shape with strong negative rake geometry.

Provides edge strength while maintaining versatility for turning, facing, and profiling.

(2) Substrate & Coating

CVD Coatings: TiCN + Al2O3 multilayer coatings for steel and cast iron, resisting crater wear.

PVD Coatings: TiAlN or AlTiN nano-coatings for stainless steel and high-temp alloys.

Submicron Carbide Substrate: Enhances toughness and prevents edge chipping.

(3) Machining Benefits

Excellent chip evacuation due to advanced chipbreaker design.

Long tool life under continuous and interrupted cuts.

Superior surface finish on steels and alloys due to stable cutting edge.

4. Application Scenarios

The DNMG150404-MA, DNMG150408-TM, and DNMG150608-TM inserts are widely applied in:

Automotive Industry – Machining engine blocks, crankshafts, and transmission components.

Aerospace Industry – Precision turning of nickel-based alloys, titanium, and stainless steels.

Energy Sector – Oilfield components, turbine housings, and valves.

General Engineering – Shafts, housings, and mold base finishing.

Heavy Industry – Large-diameter workpieces requiring stable cutting forces.

5. Key Features

High Rigidity – Negative rake geometry withstands higher cutting loads.

Flexible Use – Suitable for both roughing and finishing depending on chipbreaker design.

Multiple Cutting Edges – Indexable design provides cost-effective tool usage.

Optimized Chip Control – MA chipbreaker ensures smooth finishing, while TM provides stable roughing.

Surface Quality – Capable of achieving Ra < 1.6 µm on steels.

Reduced Downtime – Quick insert replacement increases machine uptime.

6. Differences Between MA and TM Chipbreaker

| Model | Chipbreaker Type | Best Application | Cutting Depth (ap) | Feed Rate (f) | Machining Benefit |

|---|---|---|---|---|---|

| DNMG150404-MA | Medium-Finishing | Finishing to medium | 0.2 – 2.0 mm | 0.05 – 0.25 mm/rev | Excellent chip evacuation, smooth surface |

| DNMG150408-TM | Tough Machining | Medium to roughing | 0.5 – 3.5 mm | 0.15 – 0.40 mm/rev | Strong edge for stable heavy cuts |

| DNMG150608-TM | Tough Machining | Medium to roughing | 0.8 – 4.0 mm | 0.20 – 0.45 mm/rev | Greater durability, longer tool life |

7. Precautions for Use

Tool Clamping – Ensure proper clamping torque to avoid insert movement.

Cutting Parameters – Select cutting speed and feed according to chipbreaker and material.

Coolant Use – Apply coolant for stainless steel to prevent built-up edge.

Avoid Shock Loads – While strong, inserts may fracture under extreme interrupted cuts without correct settings.

Edge Selection – Smaller nose radius (0.4 mm) for finishing, larger nose radius (0.8/0.6 mm) for roughing stability.

8. Technical & Patent Innovations

Our DNMG inserts incorporate several technological advancements:

Nano-Coating Layers – Improved adhesion, oxidation resistance, and wear life.

Grain Refinement Technology – Submicron WC grains provide better edge toughness.

Optimized Chipbreaker Design – Proprietary MA and TM geometries tested for different cutting conditions.

Cryogenic Post-Treatment – Enhances carbide matrix stability and prevents premature failure.

Green Manufacturing – Recycling of carbide scrap reduces environmental footprint.

9. Comparison with Other Inserts

DNMG vs CNMG – DNMG’s 55° angle is more versatile for profiling, while CNMG’s 80° angle is stronger for heavy roughing.

DNMG vs VNMG – DNMG provides stronger edge stability, VNMG offers better access in tight geometries.

DNMG vs TNMG – DNMG has higher precision in profiling; TNMG is more rigid for heavy machining.

10. Why Choose Our DNMG Inserts

Direct Manufacturer – Full control over carbide substrate, sintering, coating, and QC.

Tailored Grades – Custom carbide grades for steel, stainless, and superalloy applications.

OEM/ODM Service – Branding and private labeling for global distributors.

Competitive Pricing – Factory-direct solutions ensure cost savings.

International Standards – ISO-certified manufacturing processes.

Conclusion

The DNMG150404-MA, DNMG150408-TM, and DNMG150608-TM carbide turning inserts offer an outstanding combination of durability, versatility, and cutting efficiency. Whether used for finishing, medium machining, or heavy-duty roughing, these inserts deliver reliable performance across a wide range of materials.

As a professional hard alloy manufacturer, we are committed to delivering world-class carbide tooling solutions backed by patented technologies, advanced coating systems, and strict quality standards. By choosing our DNMG inserts, customers benefit from extended tool life, reduced machining costs, and superior surface finish quality.

Previous page

Next page

Use equipment

CNC machining centre

CNC machine tools

Carved machine

Factory Board

Factory Board

Factory Board

Factory Board

Factory Board

Recommended products

FAQ

2025-05-29

The naming conventions for turning inserts generally follow international standards (such as ISO standards). The model number consists of a series of letters and numbers, each character representing different geometric parameters or functional characteristics, such as the naming convention for the TNMG160404R-PV turning insert from Lizhou.

2025-05-26

What types of end mills are there?

Materials can be processed according to different types of end mills, categorized by the types of milling tools, including flat end mills, ball end mills, radius end mills, chamfer end mills, and end mills with chip breakers.

2025-05-23

PCD milling cutter is a polycrystalline diamond (PCD) milling cutter, which has a wide range of applications in the field of machining.

2025-05-08

End mill for machining aluminum materials

Many customers have told us that ordinary end mills frequently stick when machining aluminum, and the accumulation of chips affects the accuracy, so they always change the tools. LIZHOU editor suggests that coated end mills are not recommended for aluminum materials, because some coatings contain aluminum elements. Therefore, it is better to choose uncoated end mills when selecting end mills for machining aluminum materials.